Single-use plastics are taking over in supermarkets and almost everywhere else. Plastic is infamous for polluting the planet, as it can take up to 450 years to decompose. Other materials of today also come from energy-intensive manufacturing processes. They are formed by high-energy extraction methods. It is clear that the current industries are contributing to carbon emissions and non-biodegradable waste. As the world is being taken over by waste and pollution, we need alternative materials. Advancements in science and a keen interest in natural materials has started a chain of action. New materials like hemp, algae, seaweed, and mycelium are replacing plastics. These radical ideas challenge everything we know about the materials we are accustomed to. How can mycelium become part of the circular economy?

What is Mycelium?

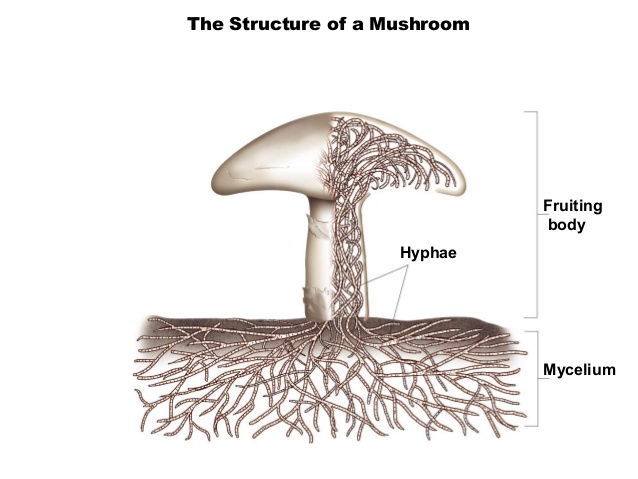

Mycelium is the vegetative part of the fungus. It is a part of the widely popular food source- mushroom. While mushroom is the flowering part of fungi, mycelium is the living root-like structure. It is found in and on soil and other substrates. Mycelium plays a pivotal role in decomposing biomass and returning nutrients back into the soil. They are the digestive systems of the natural world! Mycelium releases enzymes to break down matter and grows into a dense network of hyphae. After forming this network, mycelium transitions into growing mushrooms. Mushrooms bear spores, which are the means of reproduction. Mycelium also captures and stores carbon in the soil.

Scientists have looked for solutions in fungi for years. Fungi have found application in antibiotics, fermentation, and as a food source. Attempts are being made to look at fungi beyond food and medicine. The unique ability of mycelium to grow fibers rapidly is being applied in the field of biofabrication. Mycelium can be used as a material for packaging, vegan leather, building blocks, insulation, and food. It is available all over the world to become a brilliant base material. Moreover, companies like Ecovative are handling plastic pollution along with the issue of agricultural waste. Mycelium binds well with lignocellulose compounds to form a lightweight material. This compound is abundant in corn stalk, hemp, flax, woodchips, sawdust, cork, cereal grains, coffee grounds, and rice husks. Hence, agricultural waste is used as a substrate to grow mycelium.

Benefits of mycelium as a material

- Mycelium is available limitlessly and can be reproduced in a lab environment.

- The process is based on the growth of materials, rather than on extraction.

- The process uses much less electricity or the burning of fossil fuels. The carbon emissions are reduced by 90%.

- The manufacturing uses agricultural byproducts from farms, thus eliminating waste.

- The pulping process consumes 40% less energy and 90% less water than chemical pulping used for polystyrene.

- The material is non-toxic.

- It is lightweight, yet strong.

- The material is flexible and can take any shape that is desired. All products can be custom-made.

- It has high shock-absorbing properties.

- It has very low thermal conductivity, making it an ideal insulator.

- The products will only succumb to extreme temperatures or moisture.

- They are 100% compostable and disintegrate in 30-90 days.

- They are bio-contributing. The product nourishes the soil once it is no longer needed.

- Some companies even design their packaging in a way to provide it a second life like a bowl, coaster, or vase.

How does mycelium turn into a product?

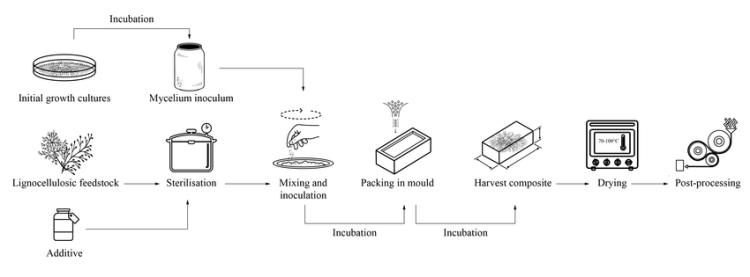

A mold is either 3D printed, hand-made, or vacuum formed. There are different molds depending on what needs to be packed. A mixture of agricultural waste, fungal spores, and water is added to the mold. The mixture is crushed into a process called enzyme pulping. This mixture is placed in growth chambers that mimic the conditions of natural soil. Mycelium grows at a temperature of 25-27 degrees celsius, 60-65% humidity, and complete darkness. The mycelium feeds on and binds with the organic waste. It grows within the mold, taking the mold’s shape.The next step is to intervene before mycelium can build mushrooms. This is done by controlling temperature, carbon dioxide, humidity, and airflow. The whole process takes about a week. It takes 5 days to form and 2 days to dry. After getting dried, it is ready to be used as durable product. It can be composted and used as a fertilizer after it has served its purpose.

Mycelium Packaging

Mycelium packaging has been developed to be used as an alternative to petroleum-based foam packaging. Styrofoam can take 20 to 500 years to decompose, often ending up in landfills and oceans. A New York-based company called Ecovative has been on this mission since 2004. The company boasts 23 patents for different techniques and methods to grow mycelium. They have developed the ‘Aerial Mycelium farming’ technology where the aerial mycelium grows up instead of mixing with the substrate. They are currently experimenting with different strains of mycelium to make materials that are water-absorbent, flame retardant, or dielectric. MycoComposite is their patented biomaterial. Dell, Ikea, and other set-ups have started using this packaging for their products. “Our packaging is a nutrient, not a pollutant. You can put it right in your garden”, says co-founder Eben Bayer.

Apart from using a renewable material, the company tries to choose other ways to reduce carbon emissions. The agricultural byproducts are sourced within 200 miles (320 kilometers) of their facility. This saves considerable energy on transportation. Plastic molds are used as growth trays. The company uses PETG for the growth trays instead of PET. The trays are softer and more pliable, allowing them to be reused easily. Their largest chamber can produce up to 200,000 pounds of mycelium per year.

Mycelium Vegan ‘Leather‘

In 2013, a company called MycoWorks used compressed mycelium to make leather. The scientists and engineers at Bolt Threads have created another leather alternative named Mylo. The material can be tanned and dyed to take any color or texture. It is being used to create bags, footwear, and clothes. Mylo is free of chemicals such as chromium and DMFa, which are found in synthetic leather. This product has been incorporated by Stella McCartney. Her company launched the world’s first garments made from Mylo in March (2021). Mylo has also been used by Adidas as they debuted the first shoe made from mycelium in April(2021). Forager hides by Ecovative are aerial mycelium turned into leather. Mycelium leather grows in 9 days!

Furniture made of Mycelium

Designer and furniture maker Sebastian Cox and researcher and designer Ninela Ivanova created ‘eco furniture’ out of mycelium and discarded willow wood. The furniture highlights the ancient relationship between wood and fungus. The stools were accompanied by lampshades also grown from mycelium. The molds were made off thin wooden strips.

Mycotecture

Mycologist Philip Ross coined the term ‘mycotecture’ in 2008 to describe the art of designing and building with mycelium. His installation was made of bricks and stacked as an arch. The bricks were made of Ganoderma lucidum (or Reishi) cultures. He collaborated with artist and writer Sophia Wang to start the company MycoWorks in 2013. Biocycler is a portable machine that produces mycelium bricks. Mycelium is used along with cellulose-based waste from construction sites. It is a fireproof material and can reach a higher hardness than concrete at the same weight. It is waterproof and mold-proof. NASA is considering mycotecture as a viable option to building houses on other planets!

The Living, an Autodesk studio headed by “biotect” David Benjamin, is using bio-computing, bio-sensing, and bio-manufacturing to harness living organisms for architecture. In 2014, they assembled 10,000 bricks to form a 13m-tall tower which was completely composted after serving as a public space for three months. This Hy-Fi tower used bricks made of mycelium to self-populate in rectangular molds.A similar use of mycelium is seen in the Growing Pavilion designed by Company New Heroes and Krown-design. Mycelium happens to capture carbon dioxide (about twice its weight!). In this case, it grew on hemp waste substrate and filled up 6 feet tall and 3 feet wide molds. Thus, the building material is reducing pollution along with having no carbon footprint. It also acts as an insulator.

Insulation Panel

BIOHM, a UK-based company is replacing toxic insulation boards with insulation panels made out of mycelium. It outperforms petroleum-based materials in thermal and acoustic insulation. The manufacturing process is carbon negative, sequestering at least 16 tonnes of carbon per month. Initial testing demonstrates that mycelium releases significantly less heat and smoke during burning. It provides excellent acoustic insulation. Tests have shown an acoustic absorption of at least 75% at 1000Hz (the typical frequency of road traffic noise).

Conclusion

Mycelium is a game-changer for current industries. The material is easily available, easy to grow, and has a variety of use cases most of which remain largely unexplored. The processes need to be more standardized in order to adopt mycelium as a go-to biomaterial. To this end, some companies (including Ecovative) supply do it yourself (DIY) kits in an attempt to open-source the material. They are willing to provide raw materials so that people can create their own products. While it will take years before mycelium can replace mainstream materials, it has potential like no other. It is less labor-intensive than hemp and more accessible than seaweed or algae.

These prototypes give hope that the products and buildings around us can in turn be healthy contributors to the biosphere. This is an inspiration and a wake-up call. As this material is still at a nascent stage, individuals and companies could collaborate with people already working with mycelium. A chain reaction can be started through workshops as well. People should feel encouraged to grow their own mycelium sculptural forms. They can experiment with mycelium from different mushroom species. This way, mycelium could show up in the mainstream markets and become part of day-to-day life.

2 thoughts on “Can Mycelium be the new biomaterial?”