Key points

- The Industrial Revolution, which took place between 1750 - 1900, was a period of great change in Britain.

- There were huge technological advances which had an impact on every aspect of life.

- These technological advances were happening while the British Empire was growing.

- Not all of these changes were positive. Conditions in factories and coal mines in particular were dangerous and difficult.

Video about the Industrial Revolution

Andrew Marr: Three hundred years ago, something new appeared above the surface of the planet, a thick oily spectre, hanging in the air, for longer than the cooking smoke from any town or city and larger than a forest fire or a volcano.

The Industrial Revolution was the biggest story to happen to mankind since we invented farming, and that dirty smear of smoke spread across north America, much of Europe, China, Japan. But it first billowed into the air over a modestly sized little island, which called itself, rather immodestly, Great Britain.

The engine for all of this was – the engine. Steam engines burned up the buried energy of millennia captured in coal and used it to create immediate power.

What a moment! Through all of history, one thing had never changed. There was a fixed limit on the amount of power that humans could use: their own muscles, a few animals, the odd windmill and waterwheel. But soon steam engines would be doing as much work in Britain as forty million people flat out.

Why did this happen in Britain? Was it because the British were uniquely clever? No.

Was it because the country seemed to be half built on coal? Not really.

It was because the British had developed a new political system which limited monarchy, gave everybody legal rights, allowed the free flow of ideas and ensured that British geniuses owned their ideas, so they could make a buck.

Manufacturing before the 1800s

Most manufacturing of textiles took place in the home. This was called the domestic systemThe method used to produce goods in the home before 1700. Usually making products by hand, with basic machinery. and was labour intensive. Production was small-scale and goods were normally sold in local markets. But Britain was also a leading European wool producer. The textiles made in Britain were often sold in Europe or sent to India and the American colonies.

From the mid-1700s onwards, machinery started to be developed to speed up the production process and to produce on a larger scale, also referred to as the factory systemThe method of goods being made mainly by machinery, in a factory. The main role of workers was to supervise and operate the equipment.. This period is known as the Industrial Revolution, although some historians say this term is misleading, as change took place over a long period of time and so shouldn’t be called a revolution.

What developments led to the Industrial Revolution?

New developments in technology and transport were integral to the industrial revolution.

The British Empire

By the mid-1700s, Britain was becoming the world’s most powerful empire. Some historians have argued that Britain’s empire and its global trading contributed to the Industrial Revolution. For example, the population of Britain’s North American colonies was growing rapidly, and they bought a lot of goods that were manufactured in Britain, creating a larger market for these goods. Money that was made from the slave trade was used to build railways in Britain. The wealth generated by the empire encouraged industrialisation in Britain.

Technology

In 1778, James Watt and Matthew Boulton invented a steam engine that could efficiently power factory machinery.

Coal was burned to heat water to make steam. This led to a huge increase in the demand for coal. Factories were opened near to supplies of water and coal so they could power their machinery. Coal mines were opened in the north of England, the Midlands and south Wales. But conditions in coal mines were dangerous. There was a risk of tunnels collapsing and poisonous or explosive gas in the mines. Steam-powered mills could produce more textiles quicker, so factory owners could look to sell their products to a wider market, both in Britain and abroad. This prompted improvements in transport.

Transport

There were huge transport changes in the 1700s and 1800s.

- Roads: Before the 1700s roads were often muddy tracks, and impassable in bad weather in the winter. Horses and carts were used to transport goods by road. From the 1700s, Turnpike TrustsGroups of people who paid to maintain or improve roads, then charge people a toll to use them. had been set up and they set up toll roads. They charged people to use roads and made improvements with the money raised. John Macadam invented tarmac in the 1820s which meant roads started to improve and were easier to use in all weather.

- Canals: In 1759, the Duke of Bridgewater paid for a canal to be dug to bring coal to his mills in Manchester. Canals were a way of transporting a large amount of goods at once using waterways. Far more goods could be transported in one journey on the canals than by road.

- Railways: The most significant transport development in the 1800s was the invention of the railway. In 1829, George Stephenson entered a competition to design a locomotiveAn engine that powers a train along a railway.. His design, named ‘the Rocket’, won the competition. He went on to design and build the Liverpool-Manchester railway, which reduced journey times from four hours by road to just two hours by train.

- The development of the railway meant the cost of transporting goods was cheaper and easier, further adding to the growth of factories.

Case study: Richard Arkwright

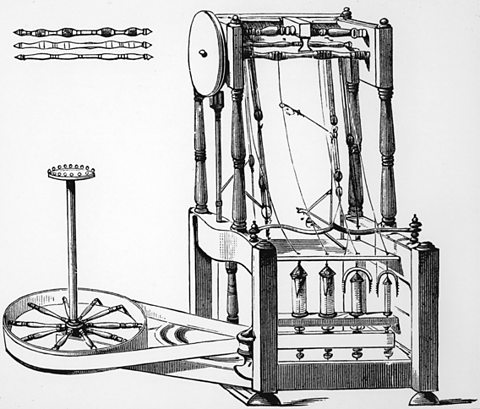

In 1764, James Hargreaves invented the Spinning JennyA machine to spin yarn or thread on more than one spindle at a time. Invented by James Hargreaves in 1764.. This was a breakthrough in the production of cloth as it could produce eight times as much material as a single spinning wheelA household machine operated by foot, that uses a spindle to spin yarn or thread that can be used to make fabrics..

Richard Arkwright was a wig maker. While travelling the country he saw the benefits of the Spinning Jenny. In 1767, he came up with his own spinning machine, called the water frame. This new machine was powered by water and was able to spin 128 threads at a time, making it much faster than the Spinning Jenny. The threads were also much stronger.

Arkwright opened a factory in Cromford in Derbyshire, and built houses near the factory for workers to live in. This was the beginning of a shift in which more British people moved from rural to urban areas to find work. Arkwright’s water frame revolutionised factory life as the machine did not have to be operated by skilled workers. It is an example of the shift away from small production to continuous mass manufacturing.

Game - mill owners

Play a History Detectives mission exploring the treatment of people that worked in the mills.

You can also play the full game.

Factory workers

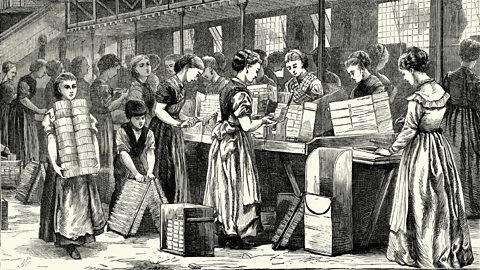

In the 1800s, it became common to employ women and children to work in factories. Before the Industrial Revolution, all but the wealthiest women worked. However, this work was normally in the home or the fields, and often took place alongside the rest of the family. As factories spread across the Midlands, North West and Scottish Lowlands, many offered job opportunities to women, particularly textile factories. In these areas, young women could earn high wages, which gave them more independence than previous generations experienced. It could be difficult to combine working in a factory with caring for young children; some women would leave young children in the care of female relatives or take them to work with them. To find out more about women's lives in the 19th century, read this guide.

Children were cheap to employ and their small hands were able to effectively operate the machinery. Unfortunately, the conditions in the factories were very dangerous. For example:

- Days were long. Children often had to work 12-14-hour shifts, six days a week.

- There was very little safety equipment, so children could be seriously injured or killed by the fast-moving machinery.

- Pay was low. Child workers received an average of 3 shillings (36p) a week.

- If children were tired and started to work slowly, there were strict punishments. Children were often beaten, or even had their ears nailed to a piece of wood.

Game - working conditions

Play a History Detectives mission exploring the dangers to children working in the mills.

You can also play the full game.

Improvements to factory work

Over time, there were changes to the way workers in factories were treated. Individual factory owners started to make improvements.

Robert Owen owned a cotton factory in New Lanark. He introduced an eight-hour working day for his workers and provided a free education for all employees.

There were eventually key changes in the law that improved factory conditions.

- 1819 Factory Act: This banned factories from employing children under nine years of age and set a maximum of 12 hours work a day for nine- to 16-year-olds.

- 1833 Factory commission: This was an investigation into the conditions workers faced, which was headed by Michael Sadler and also known as the Sadler Report. It found there were some good examples of workers being well looked after, but they heard many accounts of horrific treatment. Many workers faced physical deformities due to the nature of their work, risked disease and received poor education. This commission led to another Factory Act in 1833.

- 1833 Factory Act: This banned children of any age working before 5:30am or after 8:30pm, introduced an hour-long lunch break, made education a right for all children and introduced a factory inspection system to check that the conditions were being improved.

- 1901 Factory Act: This banned factories employing children under 12 years of age and made further rules around safety equipment. For example, all factories required fire exits.

What do you think life was like in factories before the 1833 Factory Act?

Life could be very tough for children who worked in factories. They worked exhausting, long hours and the factories could be dangerous places to be. Many children suffered life-changing injuries from the machines and awful working conditions. Employers often beat children for working slowly or arriving late.

Game - parliament and the mills

Play a History Detectives mission exploring how parliament dealt with the conditions for children in the mills.

You can also play the full game.

The growth of cities

From 1700 to 1900, there was big shift in people living in villages to moving into towns and cities for work. In 1801 a censusA national survey that counts the population of a country. was completed. The data from this shows the growth in city sizes and it can be compared with modern cities.

| City | Population in 1801 | Population in 1901 | Population in 2011 |

|---|---|---|---|

| London | 959,000 | 6,339,500 | 9,787,426 |

| Manchester | 90,000 | 543,900 | 2,553,379 |

| Liverpool | 80,000 | 702,200 | 864,122 |

| Birmingham | 74,000 | 522,200 | 1,085,810 |

Homes for factory workers were often built by the factory owners and were of poor quality. They were cramped and families often lived in the same room. Some even had to live in damp cellars. sanitationAccessibility of clean drinking water and hygienic waste disposal. was poor and disease was common. There were several choleraA waterborne disease that was spread through contaminated water. It caused severe diarrhoea and sometimes death. outbreaks in the 1800s due to poor quality water supply. A Public Health Act was passed in 1875, which set out standards for local authorities to improve water supply, sewage and said every town should appoint a medical officer.

Test your knowledge

Where next?

History Detectives game. gameHistory Detectives game

Analyse and evaluate evidence to uncover some of history’s burning questions in this game