TensionRite® Belt Frequency Meter - Applied Industrial Technologies

TensionRite® Belt Frequency Meter - Applied Industrial Technologies

TensionRite® Belt Frequency Meter - Applied Industrial Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

pT oe wn es r i otnrRa intse m ®<br />

i Bs es li ot n f Pr Re OqDuUeCnT cS y M etensionrite t e r<br />

®<br />

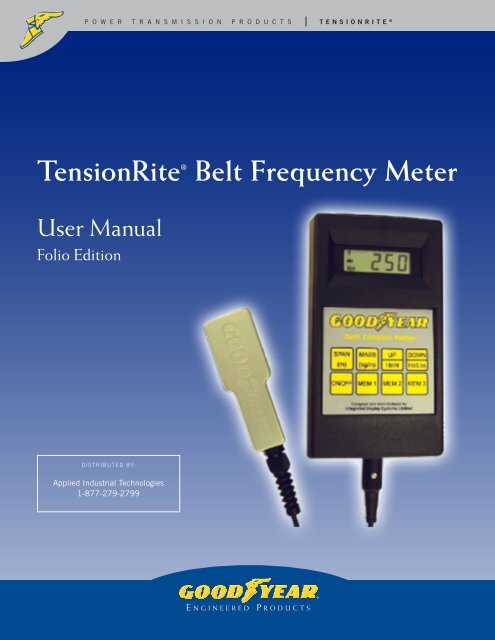

TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong><br />

User Manual<br />

Folio Edition<br />

Distributed By:<br />

<strong>Applied</strong> <strong>Industrial</strong> <strong>Technologies</strong><br />

1-877-279-2799<br />

1

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

Table of Contents<br />

SECTION<br />

PAGE<br />

1.0 Safety Tips...................................................... 3<br />

2.0 Device Description........................................... 4<br />

3.0 Quick Start...................................................... 5<br />

4.0 Functions<br />

4.1 Keys...................................................... 6<br />

4.2 Audio/Visual Display............................... 8<br />

4.3 Optical Sensor........................................ 9<br />

4.4 Battery Condition.................................... 10<br />

4.5 Charging Batteries.................................. 11<br />

5.0 Setup & Use Procedure.................................... 12<br />

6.0 Operating Tips................................................. 14<br />

7.0 <strong>Meter</strong> Range.................................................... 15<br />

8.0 Calibration<br />

8.1 Spot Check............................................ 16<br />

8.2 Annual Certification................................ 17<br />

9.0 Technical Specifications................................... 18<br />

10.0 Useful Formulas & Conversions......................... 19<br />

Appendix<br />

1.0 <strong>Belt</strong> Mass Constants............................... 20<br />

2.0 Theory of Operation................................ 23<br />

3.0 FAQ’s.................................................... 24<br />

4.0 Tensioning Tables................................... 28<br />

5.0 Limited Warranty.................................... 30<br />

2

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

1.0 GENERAL SAFETY TIPS<br />

SAFETY FIRST – Read and understand this manual before operating the<br />

TensionRite ® <strong>Meter</strong>.<br />

• Do not drop meter or subject either meter or optical sensor to other sharp impact.<br />

• Do not put water, solvents (including cleaning solutions) or any other liquid on the<br />

unit. Clean meter and sensor with a dry cotton cloth.<br />

• Do not pull on sensor cord. Disconnect sensor from meter by grasping the connector<br />

grip only.<br />

• Do not leave the unit in places that are humid, hot, dust filled or in direct sunlight.<br />

Hint: When the TensionRite ® <strong>Meter</strong> is not to be used for a while, remove the<br />

batteries and store unit in the case provided.<br />

• Do not use your TensionRite ® <strong>Meter</strong> in any explosive environment.<br />

• Do not disassemble or attempt to modify either the meter or the sensing head.<br />

LOCK OUT – TAG OUT<br />

Switch off and isolate any belt drive system prior to taking tension measurements or<br />

attempting any other installation work.<br />

3

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

2.0 Device Description<br />

LED<br />

Aiming<br />

Beam<br />

Display<br />

Window<br />

see Section 4.2<br />

Key Pad<br />

see Section 4.1<br />

Optical Sensor<br />

see Section 4.3<br />

Cable<br />

Plug-in<br />

The TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> from Goodyear Engineered Products is a two<br />

component system consisting of a hand-held meter attached to an optical sensor via<br />

an electronic cable. The sensor uses an infrared beam to detect the vibration of a belt<br />

strand and sends a signal to the meter. (The sensor includes an LED that produces an<br />

orange light beam to help aim the invisible infra-red ray). Comparing this input to the<br />

vibration of a quartz crystal, the meter computes the natural frequency of the belt. The<br />

result is shown in the display window as hertz (oscillations per second). The internal<br />

programming of the meter is also able to report the belt tension in units of force (either<br />

newtons or pounds-force) provided the operator has entered the belt mass and span<br />

length using the manually operated key pad.<br />

The meter operates on four “AA” batteries. Battery life is approximately 20 hours. The<br />

battery compartment is accessible at the back of the meter.<br />

An abridged manual, a tuning fork for checking calibration and a storage case are<br />

included with the complete kit.<br />

4

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

3.0 Quick Start<br />

Following these simple steps will allow you to measure the vibration frequency of the<br />

belt. This value is independent of span or mass values but is very useful as an index for<br />

belt system maintenance, sometimes the only number you will need. For example, the<br />

MAXIMIZER drive analysis program gives tensioning targets in Hz as well as in force<br />

units (newtons and pounds-force).<br />

For tensioning results in units of force, follow the procedures defined in Section 5.0.<br />

5

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

4.0 Functions<br />

4.1 Keys<br />

ON/OFF<br />

SPAN<br />

(m)<br />

MASS<br />

(kg/m)<br />

This key switches the meter on or off. If the meter is on and sits idle for<br />

more than 3 minutes, it automatically switches off to preserve battery life.<br />

When the meter is first switched on a battery check is made. See Section<br />

4.4 for a description of the visual and audible low battery signal.<br />

This key is used to enter the belt span length. Hold down the span key and<br />

use the UP or DOWN keys to set the belt span in meters. Releasing the<br />

span key results in an audible beep to indicate the setting has been<br />

accepted. Pressing a MEM(ory) key immediately after releasing the SPAN<br />

key will load the span constant just entered into the appropriate memory<br />

register. Pressing the SPAN key alone shows the current setting.<br />

This key is used to enter the belt mass. Hold down the mass key and use<br />

the UP or DOWN keys to set the belt mass in kilograms/meter (kg/m)).<br />

Releasing the mass key results in an audible beep indicating that the<br />

setting has been accepted. Pressing a MEM(ory) key immediately after<br />

releasing the MASS key will load the mass constant just entered into the<br />

appropriate memory register. Pressing the MASS key alone displays the<br />

current setting.<br />

Important Note:<br />

<strong>Belt</strong> span and belt mass are required entries if tension results in force units (newtons or<br />

pounds-force) are desired. Entries must be in SI units (meters and kg/meter).<br />

UP<br />

(Hz/N)<br />

This key has two functions. The first is to increase either the SPAN or<br />

MASS parameters when used in conjunction with those keys. The second<br />

use is to toggle between the Hz and the newton measurement modes. If<br />

this key is pressed while either the SPAN or MASS keys are being held<br />

down, the number shown in the display window will increase in value. If<br />

only this key is pressed, the display will automatically toggle between<br />

frequency and newtons. The calculation of the force in newtons will be<br />

based upon the mass and span constants currently in the active register.<br />

6

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

DOWN<br />

(Hz/Lbs)<br />

This key has two functions. The first is to decrease either the SPAN or<br />

MASS parameters when used in conjunction with those keys. The second<br />

use is to toggle between the Hz and the pounds-force measurement modes.<br />

If this key is pressed while either the SPAN or MASS keys are being held<br />

down, the number shown in the display window will decrease in value.<br />

If only this key is pressed, the display will automatically toggle between<br />

frequency and pounds. The calculation of the force in pounds will be based<br />

upon the mass and span constants currently in the active register.<br />

MEM 1<br />

MEM 2<br />

MEM 3<br />

The memory keys allow up to three sets of belt parameters to be stored<br />

in the meter registry. Pressing the MEM 1 key recalls the first set of belt<br />

parameters and likewise for MEM 2 and MEM 3. To store the belt<br />

parameters to a key, the belt span and mass parameters must first be<br />

entered and then immediately after release of either the SPAN or MASS<br />

keys the selected MEM key should be pressed. Two beeps indicate that<br />

the parameters have been successfully assigned to the key.<br />

To use the stored span and mass constants simply press the desired<br />

MEM(ory) key prior to taking a measurement. To check if you have the<br />

correct values you may press the SPAN or MASS keys and the current<br />

constant will show in the display window.<br />

7

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

4.0 Functions<br />

4.2 Audio/Visual Display<br />

The TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> is an interactive tool. It provides<br />

both visual and audible communication with the operator. Each signal or<br />

combination of signals has meaning. While all these signals are discussed<br />

in other sections of this manual, here will be presented a compilation of all<br />

the available signals.<br />

Generally visual signals alone give measurement results while audible<br />

signals, either alone or in combination with a visual signal, indicate some<br />

operational step.<br />

VISUAL MEASUREMENT RESULTS<br />

Hz<br />

lbs<br />

N<br />

lbs<br />

N<br />

Hz<br />

000<br />

000<br />

000<br />

Tension displayed in newtons<br />

<strong>Frequency</strong> mode, results displayed as hertz (cycles/sec).<br />

Tension displayed in pounds-force.<br />

A dark oval will appear to indicate the units associated with the number<br />

displayed.<br />

AUDIBLE SIGNALS<br />

Signal when means<br />

One beep Upon release of “Span” key Input accepted<br />

Upon release of “Mass” key<br />

Input accepted<br />

While sensor is aimed at vibrating belt Measurement taken<br />

Two beeps Upon pushing “memory” key after Span data has been stored<br />

releasing “Span” key<br />

Upon pushing “memory” key after Mass data has been stored<br />

releasing “Mass” key<br />

Four beeps Combined with “000” newton display Newton result is out of range<br />

Combined with “000” pound display Pound result is out of range<br />

After pushing “On” key and combined Low battery condition<br />

with “zero” countdown<br />

8

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

4.0 Functions<br />

4.3 Optical Sensor<br />

The sensor uses an invisible infrared beam to detect vibrations of the belt.<br />

A narrow angle orange LED generated beam is provided to guide the aiming<br />

of the sensor.<br />

The very best signal from the belt is seen<br />

when the sensor is held perpendicular to<br />

the belt at the center of the span and at<br />

a 3/8” (9.5mm) distance. It is also a good<br />

practice to orient the long edge of the<br />

sensor head parallel to the centerline of<br />

the belt. This helps to reduce the effect<br />

of any divergence between the aiming<br />

beam and the infrared sensing beam.<br />

When physical restrictions are present, it is possible to get useable readings<br />

with the sensor at up to 2” distance from the belt and/or tipped up to 45<br />

degrees from perpendicular.<br />

It is possible to take measurements from<br />

the edge of the belt. The toothed side of<br />

a belt is equally acceptable as a target<br />

for the sensor.<br />

The sensor LED’s should be kept clean by wiping with a soft cotton cloth.<br />

Solvents are never to be used.<br />

9

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

4.0 Functions<br />

4.4 Battery Condition<br />

When the TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> is first switched on, a<br />

battery condition check is automatically performed. A low battery condition<br />

is signaled both visually and audibly. The display window will flash an array<br />

of zeros, starting with four and progressing to only one. There will be an<br />

audible signal of four “beeps” as the display changes.<br />

N<br />

Hz<br />

lbs<br />

N<br />

Hz<br />

lbs<br />

N<br />

Hz<br />

lbs<br />

N<br />

Hz<br />

lbs<br />

0000<br />

000<br />

00<br />

0<br />

BEEP<br />

BEEP<br />

BEEP<br />

BEEP<br />

Low<br />

Battery<br />

Signal<br />

If these signals are seen and heard, batteries should be replaced. Batteries<br />

are accessed through the removable cover on back of meter. New batteries<br />

should be inserted within 30 seconds of removal of old batteries. Taking<br />

longer risks loss of any data stored by the memory keys.<br />

Batteries are expected to provide approximately 20 hours of continuous<br />

operation before replacement is required.<br />

Dispose of old batteries in an environmentally sensitive manner as prescribed<br />

by the battery manufacturer. In no case should the batteries be disposed of<br />

in open flame.<br />

10

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

4.0 Functions<br />

4.5 Charging Batteries<br />

— IMPORTANT —<br />

Do not charge batteries with the sensor head attached to the meter. Do<br />

not attempt to use the meter while batteries are being charged. Damage<br />

to the optical sensor could result.<br />

The TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> is compatible with user supplied<br />

rechargeable batteries and recharging unit. A convenient 3.5mm, positive<br />

center charging socket is located on the bottom end of the meter body<br />

adjacent to the sensor cable plug-in port.<br />

• Batteries – 1300 mAH minimum (user supplied)<br />

• Charging unit – 12 to 15 volt DC output (user supplied)<br />

• Connection – 3.5mm O.D. positive tip mini plug/socket<br />

The built-in circuit of the meter controls the charging current, automatically<br />

providing a fast and a trickle charge. Charging current is internally limited<br />

to 100 mA. Charging time is typically 12-14 hours for a full charge.<br />

You may turn the unit on while charging. The meter’s software will then<br />

signal that the batteries are charging. The display window will flash an<br />

array of zeros, starting with only one and progressing to four. There will<br />

be an audible signal of four “beeps” as the display changes.<br />

Alternatively, a separate battery charging station may be utilized. Using two<br />

sets of batteries, one set in use with the meter, the other set in the charging<br />

station would ensure freshly charged batteries were always available. Again,<br />

batteries should have a minimum rating of 1300 mAH.<br />

11

MEM 3<br />

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

ON/OFF<br />

5.0 Setup & Use Procedure<br />

SPAN<br />

(m)<br />

1. Plug sensor head into meter body.<br />

This is a keyed plug. Line it up,<br />

do not use force!<br />

ON/OFF<br />

MASS<br />

(kg/m)<br />

SPAN<br />

2. Turn unit on by pressing<br />

(m)<br />

ON/OFF<br />

ON/OFF<br />

3. Load span and mass data or recall previously loaded data.<br />

To load span data simply hold down<br />

(kg/m)<br />

UP<br />

DOWN<br />

while using or to set the number.<br />

(Hz/N)<br />

(Hz/Lbs)<br />

When the correct number appears in the display window, simply release the<br />

(Hz/Lbs)<br />

(kg/m) MASS<br />

SPAN key. The unit will beep once to acknowledge acceptance of this setting.<br />

To load mass data simply hold down<br />

DOWN<br />

(Hz/Lbs)<br />

MASS<br />

DOWN<br />

(Hz/Lbs)<br />

UP<br />

SPAN ON/OFF<br />

while using or to set the number.<br />

(Hz/N)<br />

(m)<br />

DOWN<br />

MASS<br />

MEM<br />

DOWN<br />

1<br />

(Hz/Lbs)<br />

SPAN<br />

(m)<br />

SPAN<br />

(m)<br />

(kg/m)<br />

MASS<br />

(kg/m)<br />

MEM 2<br />

When the correct number appears MEM 1 in the display window, simply release the<br />

MASS key. The unit will beep once to acknowledge acceptance of this setting.<br />

UP<br />

(Hz/N)<br />

To save individual MEM 1entries into MEM 3memory, 2 press the appropriate memory key<br />

UP<br />

(Hz/N)<br />

MEM 1<br />

, MEM 2 or<br />

MEM 3<br />

MEM 1<br />

UP<br />

(Hz/N)<br />

as soon MEM 2as the MEM span 3 or mass keys have been released. The meter will beep<br />

twice to acknowledge the entry MEM 2 into memory.<br />

12

MEM 1<br />

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

MEM 1<br />

MEM 2<br />

To recall stored span and mass data simply press , MEM 2 or<br />

MEM 1<br />

MEM 3<br />

according to where you previously entered the values.<br />

MEM 2<br />

MEM 3<br />

4. Aim sensor at center of selected<br />

belt span. (Best ON/OFF practice is to orient<br />

sensor with the long edge parallel to<br />

the belt centerline as shown. Best<br />

gap is approximately ½˝.) Tap or<br />

pluck the belt. Tapping the belt with<br />

SPAN<br />

the handle of a small tool such as a<br />

(m)<br />

screwdriver is a good way to make<br />

the belt vibrate. The meter will beep<br />

once to indicate that a measurement<br />

was taken.<br />

MEM 3<br />

MASS<br />

(kg/m)<br />

5. Display window will show frequency results.<br />

Hz<br />

lbs<br />

97.4<br />

UP<br />

6. Press to toggle results to newtons.<br />

(Hz/N)<br />

N<br />

lbs<br />

0225<br />

DOWN<br />

7. Press to toggle results to pounds ƒ .<br />

(Hz/Lbs)<br />

N<br />

Hz<br />

0050<br />

NOTE: Pressing either toggle a second time will return display to the Hz value.<br />

8. Readjust belt tension and repeat measurement until target tension results are attained.<br />

MEM 1<br />

13

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

6.0 Operating Tips<br />

Here are some procedures and “best” practices that may ease use or help increase<br />

the reliability of your belt tensioning efforts.<br />

LOCK OUT - TAG OUT<br />

• Take your tension reading as close to the center of the selected span as is practical.<br />

• Use the longest belt span that can be readily accessed. Minimum useable span length<br />

is equal to 20 times the belt tooth pitch for synchronous belts and 30 times the belt<br />

top width for “V” configuration belts. Using too short a span yields indicated tensions<br />

that may be much higher than actual belt tension due to effects of belt stiffness.<br />

• When possible, orient the sensor head with the long edge of the sensor parallel to<br />

the centerline of the belt. This tends to eliminate any non-reading condition due to<br />

aiming error.<br />

• On new installations, hand rotate the system at least one full revolution of the belt to<br />

seat and normalize the components.<br />

• If the top surface of the belt is not accessible, try to beam the sensor against the edge<br />

of the belt. The inside surface of the belt is equally acceptable.<br />

• The meter will not give a measurement for a belt under extremely low tension. Simply<br />

increase the drive tensioning until the meter responds. The meter will beep to indicate<br />

that a reading has been taken.<br />

• It is a good practice to take three successive readings. This will show the consistency<br />

of your methods. If the readings vary by more than 10%, reassess your measurement<br />

technique.<br />

• Taking multiple readings at different belt orientations may help you identify problems<br />

with other drive components. Tension excursions are indicative of component problems<br />

such as a bent shaft, poorly mounted sprocket or pulley or an irregular pulley groove.<br />

• The TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> will measure vibration frequency (Hz) of all<br />

style belts, even belts from manufacturers other than Goodyear Engineered Products.<br />

Tension values will also be computed provided you input the appropriate span and<br />

mass constants.<br />

• When tensioning an array of multiple V-belts, use a single belt toward the center<br />

of the array. Banded belts (Torque Team ® , etc.) are to be treated as a single unit with<br />

the mass constant calculated as a multiple of the single belt value (see “<strong>Belt</strong> Mass<br />

Constants”).<br />

14

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

7.0 <strong>Meter</strong> Range<br />

The TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> is capable of measuring belt vibration frequencies<br />

between 10Hz and 400Hz.<br />

If the measured frequency is below 10Hz, the meter will display “10.00” briefly and then<br />

change to “000.0”. If the measured frequency is above 400Hz, the meter will display<br />

“400” briefly and then change to “000”.<br />

If these limits are exceeded on a multi-shaft (three or more shafts) system it may be<br />

possible to get valid measurements by selecting a different belt span for measurement.<br />

If the measured frequency is below 10Hz choose an available shorter span. If the<br />

measured frequency is above 400HZ choose a longer span if available.<br />

It is possible to have a frequency reading that is within the meter’s range but the<br />

calculated force numbers are beyond the meter’s range. The meter is capable of<br />

calculating belt tensions up to 9,990 newtons and 2,200 pounds-force. When these<br />

limits are exceeded the meter will react as follows.<br />

Hz<br />

lbs<br />

000<br />

N<br />

000<br />

Hz<br />

BEEP<br />

BEEP<br />

BEEP<br />

A“000” newton reading accompanied by four<br />

“beeps” indicates the result is out of range.<br />

A“000” pound reading accompanied by four<br />

“beeps” indicates the result is out of range.<br />

BEEP<br />

BEEP<br />

BEEP<br />

BEEP<br />

BEEP<br />

<strong>Belt</strong> tensions greater than these values are unusual. It is therefore advisable to<br />

check that the span and mass parameters have been entered correctly. If they are<br />

found to be correct then check the calculation of your target values. If everything<br />

looks correct then this drive is simply beyond the capacity of the meter’s tension<br />

range. The drive will have to be tensioned by using frequency (Hz) values alone. Of<br />

course, traditional force and deflection techniques can also be used.<br />

SPECIAL NOTE:<br />

Tensioning a drive generally involves moving one component shaft with respect to<br />

another. On some drives, especially larger installations, tensioning the drive will<br />

involve sufficient movement that the span length is appreciably altered. <strong>Frequency</strong><br />

(Hz) values will remain accurate but if a precise tension value is to be calculated it<br />

may become necessary to update the span input to reflect the new shaft spacing.<br />

15

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

8.0 Calibration<br />

8.1 Spot Check<br />

The measurement system of the TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> is<br />

based upon a very stable quartz crystal that should never wander. However,<br />

a precision mechanical resonator (tuning fork) is included with the meter<br />

so that a calibration check at a spot frequency of 250Hz may be preformed<br />

at any time.<br />

Tap tip of the tuning fork on a hard<br />

surface and then hold steady in front<br />

of optical sensor at a distance of 1⁄2”.<br />

The meter will measure a frequency<br />

of 250HZ thus demonstrating that it<br />

is in calibration.<br />

Results within +/- 1% are acceptable. There is no adjustment possible. If<br />

greater variance is experienced, meter should be returned for recalibration.<br />

See Section 8.2 for recalibration return procedures.<br />

16

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

8.0 Calibration<br />

8.2 Annual Certification<br />

Technical support relating to calibration certification and/or operation of<br />

the TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> can be obtained from the<br />

manufacturer at:<br />

techsupport@clavis.co.uk<br />

phone: 011-44-191-2627869<br />

fax: 011-44-191-2620091<br />

The meter may be returned to the manufacturer for repair or<br />

recalibration at any time.<br />

a factory calibration certificate is included with each meter. Although the<br />

very stable solid-state quartz crystal based system is not likely to go out of<br />

calibration, some operating procedures call for annual gauge certification.<br />

for certification/calibration purposes the meter may be returned to the<br />

manufacturer at yearly intervals to have the meter recalibrated and certified<br />

to NAMAS / UKAS (National Accreditation of Measurement and Sampling /<br />

united Kingdom Accreditation Standards) standards.<br />

The manufacturer must be contacted for detailed cost and shipping<br />

procedures prior to any return. Contact information for Integrated Display<br />

systems Limited (Clavis) is shown in Appendix 5.0.<br />

There will be a charge for these services.<br />

17

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

9.0 Technical Specifications<br />

Measurement Range<br />

<strong>Frequency</strong> Range.................................. 10 to 400Hz<br />

Measurement Accuracy<br />

Below 100Hz.................................. +/- 1 significant digit<br />

Above 100Hz.................................. +/- 1%<br />

<strong>Belt</strong> Mass input range........................... 0.001 to 0.990kg/m<br />

<strong>Belt</strong> Span input range........................... 0.001 to 9.990 meters<br />

Maximum <strong>Belt</strong> Tension display............... 9990 newtons<br />

2200 pounds<br />

Environmental conditions<br />

Operating Temperature.......................... +10°C to +50°C<br />

+50°F to +122°F<br />

Shipment & Storage Temp..................... -5°C to +70°C<br />

+23°F to +158°F<br />

Protection Class................................... IP54<br />

Sensor<br />

Type.................................................... Infra-red Optical<br />

IR Wavelength...................................... 970mm<br />

Visible Aiming Beam............................. Narrow angle orange LED<br />

Housing............................................... Machined Aluminum<br />

Cable length........................................ 1 meter<br />

Power Supply<br />

Type.................................................... Dry Cell Battery<br />

Voltage................................................ 6 volt<br />

Battery Type......................................... AA (MN1500) Alkaline<br />

Number............................................... 4<br />

Expected life........................................ 20 hours<br />

Compartment location........................... back of meter<br />

Optional Rechargeable Batteries<br />

Battery Type......................................... AA (1300 mAH min.)<br />

Charger............................................... 12 – 15VDC output<br />

Socket/Polarity..................................... 3.5mm OD/positive center<br />

18

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

10.0 Formulas & Conversions<br />

Force Conversion Constants<br />

newtons x 0.2248 = pounds ƒ<br />

poundsf x 4.4482 = newtons<br />

kilograms x 9.8067 = newtons<br />

Length Conversion Constants<br />

Span Length Calculation<br />

inches x 0.0254 = meters<br />

meters x 39.3701 = inches<br />

mm x 0.001 = meters<br />

S =<br />

CD 2 - (D-d)2<br />

4<br />

where:<br />

S = Span Length (mm)<br />

CD = Center Distance (mm)<br />

D = Large Pulley Diameter (mm)<br />

d = Small Pulley diameter (mm)<br />

Weight (for Mass calculation use)<br />

ounces x 0.02835 = kilograms<br />

pounds x 0.45359 = kilograms<br />

Reminder: <strong>Belt</strong> span and belt mass inputs to the meter must be<br />

in SI units, meters for the belt span and kg/m for the belt mass.<br />

19

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

Appendix<br />

1.0 <strong>Belt</strong> Mass Constants<br />

<strong>Belt</strong> Mass is defined as weight per unit length and is expressed as<br />

kilograms per meter (kg/m).<br />

EAGLE Pd <br />

Pitch Width <strong>Belt</strong> Mass<br />

kg/m<br />

8M......... Yellow....... 0.071<br />

White........ 0.142<br />

Purple....... 0.283<br />

14M....... Blue.......... 0.254<br />

Green........ 0.380<br />

Orange...... 0.507<br />

Red........... 0.761<br />

FALCON Pd ®<br />

Pitch Width <strong>Belt</strong> Mass<br />

kg/m<br />

8M......... 12mm....... 0.064<br />

21mm....... 0.112<br />

36mm....... 0.192<br />

62mm....... 0.330<br />

14M....... 20mm....... 0.163<br />

37mm....... 0.301<br />

68mm....... 0.550<br />

90mm....... 0.738<br />

125mm..... 1.023<br />

HAWK Pd ®<br />

Pitch Width <strong>Belt</strong> Mass<br />

kg/m<br />

5M......... 9mm......... 0.034<br />

15mm....... 0.057<br />

25mm....... 0.095<br />

8M......... 20mm....... 0.118<br />

30mm....... 0.176<br />

50mm....... 0.289<br />

85mm....... 0.507<br />

14M....... 40mm....... 0.438<br />

55mm....... 0.583<br />

85mm....... 0.913<br />

115mm..... 1.233<br />

170mm..... 1.835<br />

20M....... 115mm..... 1.583<br />

170mm..... 2.341<br />

230mm..... 3.167<br />

290mm..... 3.993<br />

340mm..... 4.681<br />

BLACKHAWK Pd <br />

Pitch Width <strong>Belt</strong> Mass<br />

kg/m<br />

8M......... 12mm....... 0.045<br />

22mm....... 0.069<br />

35mm....... 0.159<br />

60mm....... 0.226<br />

14M....... 20mm....... 0.164<br />

42mm....... 0.344<br />

65mm....... 0.532<br />

90mm....... 0.737<br />

120mm..... 0.983<br />

20

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

Pd (trapezoidal)<br />

Pitch Width <strong>Belt</strong> Mass<br />

kg/m<br />

MXL........ 0.12”........ 0.006<br />

0.19”........ 0.009<br />

0.25”........ 0.010<br />

XL ......... 0.25”........ 0.014<br />

0.37”........ 0.023<br />

L............ 0.50”........ 0.047<br />

0.75”........ 0.071<br />

1.00”........ 0.094<br />

H............ 0.75”........ 0.083<br />

1.00”........ 0.111<br />

1.50”........ 0.167<br />

2.00”........ 0.222<br />

3.00”........ 0.333<br />

XH.......... 2.00”........ 0.549<br />

3.00”........ 0.823<br />

4.00”........ 1.098<br />

XXH........ 2.00”........ 0.782<br />

3.00”........ 1.172<br />

4.00”........ 1.563<br />

5.00”........ 1.954<br />

DUAL Hi-Performance Pd <br />

Pitch Width <strong>Belt</strong> Mass<br />

kg/m<br />

8M......... 20mm....... 0.206<br />

30mm....... 0.313<br />

50mm....... 0.517<br />

85mm....... 0.876<br />

14M....... 40mm....... 0.739<br />

55mm....... 1.006<br />

85mm....... 1.548<br />

DUAL Pd (trapezoidal)<br />

Pitch Width <strong>Belt</strong> Mass<br />

kg/m<br />

XL.......... 0.25”........ 0.028<br />

0.37”........ 0.040<br />

L............ 0.50”........ 0.053<br />

0.75”........ 0.080<br />

1.00”........ 0.107<br />

H............ 0.75”........ 0.092<br />

1.00”........ 0.122<br />

1.50”........ 0.183<br />

2.00”........ 0.244<br />

3.00”........ 0.366<br />

Super Torque Pd ®<br />

Pitch <strong>Belt</strong> Mass<br />

kg/m<br />

S3M....... 0.061 x inch width<br />

S4.5M.... 0.090 x inch width<br />

S5M....... 0.100 x inch width<br />

S8M....... 0.143 x inch width<br />

S14M..... 0.298 x inch width<br />

POLY-V ®<br />

Pitch<br />

<strong>Belt</strong> Mass<br />

kg/m<br />

J............. 0.009 x # of ribs<br />

K............ (weigh actual belt)<br />

L............ 0.041 x # of ribs<br />

M........... 0.154 x # of ribs<br />

21

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

HY-T ® WEDGE<br />

Pitch <strong>Belt</strong> Mass<br />

kg/m<br />

3V.......... 0.086<br />

5V.......... 0.207<br />

8V.......... 0.581<br />

3VX........ 0.073<br />

5VX........ 0.169<br />

8VX........ 0.561<br />

HY-T ® WEDGE TORQUE TEAM ®<br />

Pitch <strong>Belt</strong> Mass<br />

kg/m<br />

3VX........ 0.096 x # of ribs<br />

5VX........ 0.217 x # of ribs<br />

3V.......... 0.103 x # of ribs<br />

5V.......... 0.249 x # of ribs<br />

8V.......... 0.598 x # of ribs<br />

HY-T ® PLUS<br />

Pitch <strong>Belt</strong> Mass<br />

kg/m<br />

A............ 0.100<br />

B............ 0.162<br />

C............ 0.296<br />

D............ 0.671<br />

TORQUE TEAM PLUS ®<br />

Pitch <strong>Belt</strong> Mass<br />

kg/m<br />

5VF........ 0.242 x # of ribs<br />

8VF........ 0.615 x # of ribs<br />

TORQUE-FLEX ®<br />

Pitch <strong>Belt</strong> Mass<br />

kg/m<br />

AX.......... 0.080<br />

BX.......... 0.161<br />

CX.......... 0.290<br />

HY-T ® TORQUE TEAM ®<br />

Pitch <strong>Belt</strong> Mass<br />

kg/m<br />

B............ 0.216 x # of ribs<br />

C............ 0.367 x # of ribs<br />

D............ 0.755 x # of ribs<br />

BX.......... 0.213 x # of ribs<br />

CX.......... 0.344 x # of ribs<br />

HEX (double-V)<br />

Pitch <strong>Belt</strong> Mass<br />

kg/m<br />

AA.......... 0.137<br />

BB.......... 0.238<br />

CC.......... 0.407<br />

CCP........ 0.602<br />

FHP<br />

Pitch<br />

<strong>Belt</strong> Mass<br />

kg/m<br />

2L.......... 0.031<br />

3L.......... 0.066<br />

4L.......... 0.099<br />

5L.......... 0.144<br />

22

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

Appendix<br />

2.0 Theory of Operation<br />

The vibration frequency of a plucked string is dependant upon the tension<br />

of that string. As the tension is increased, the vibration frequency also<br />

increases. Laboratory investigations show that power transmission belts<br />

react in a similar manner. Data indicates that there is a direct<br />

relationship between belt tension and a belt’s natural frequency of<br />

vibration. This relationship holds true except for the very extreme<br />

high-tension zones (well above where any belt system can operate). Using<br />

load cells and accelerometers while applying Newtonian law, the linkage<br />

between strand tension and natural vibration frequency has been defined.<br />

It was found that unlike with string, the mass of a belt does play a role<br />

in the results. The relationship between tension and frequency has been<br />

determined to be:<br />

T = 4ml 2 f 2<br />

where<br />

T = belt tension in newtons (N)<br />

m = mass per unit length expressed as kilograms/meter (kg/m)<br />

l = span length in meters (m)<br />

f = vibration frequency in Hertz (Hz)<br />

String theory ignores flexural stiffness. A belt does have some stiffness so<br />

the calculated tension for a given frequency will be slightly higher than the<br />

actual tension. For belt spans greater than 0.25m the above equation will<br />

provide results within 10% of the actual values. Beam analysis may give<br />

improved accuracy but the required inputs are generally too cumbersome<br />

for field application.<br />

The TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> is a dual function tool. The optical<br />

sensing head uses an invisible infrared beam to detect vibration while the<br />

integral calculator determines the time base and performs the necessary<br />

calculations to support the results shown in the display window.<br />

The Goodyear Engineered Products’ TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong><br />

may be used with a power transmission belts regardless of type or<br />

construction.<br />

23

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

Appendix<br />

3.0 Frequently Asked Questions (FAQ)<br />

I am more comfortable using inches and pounds rather than millimeters and newtons. Why SI units?<br />

<strong>Belt</strong> tensioning became particularly critical with the advent of 2 nd generation synchronous belts. All<br />

such belts are of metric design with the tooth pitch, width and length specified in SI (System<br />

International d’Unites) units. It follows that tools for use with such belts should also utilize the SI<br />

system. While the TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> requires span and mass inputs to be made in SI<br />

units, the output can be toggled to pounds-force if you wish. Conversion factors for English to SI and SI to<br />

English are also shown in the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> User Manual.<br />

Which is the best span to use when tensioning a multi-span drive (a dR with more than one dN)? Best<br />

practice is to use the longest span that can be readily accessed. Using too short a span can<br />

compromise accuracy. The natural frequency of a span should be between 10 Hz and 400 Hz to be<br />

properly read by the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong>. It is highly unlikely that your drive will be outside<br />

this window. However, if the measured frequency is below 10 Hz, choose a shorter span. If the measured<br />

frequency is above 400 Hz, chose a longer span.<br />

What constitutes “too short a span” and why? Let’s start with the “why” part of your question.<br />

Transverse vibration of string theory (the science behind frequency based tension measurement)<br />

overlooks the rigidity of the string. Although hard to quantify, belts have considerable internal rigidity<br />

(stiffness). The shorter the span, the greater is the effect of this stiffness in dampening both the<br />

natural frequency and amplitude of strand vibration. The effect is that belt tension in a short span is<br />

lower than the vibration frequency would indicate (measured results are much higher than actual belt<br />

conditions).<br />

To limit such error there have evolved some informal guidelines for the most common belt<br />

constructions. For synchronous belts (toothed belts) the recommended minimum span length is<br />

defined as greater than 20 times the tooth pitch. For example: an 8mm pitch belt would require a<br />

minimum span of 160mm (approximately 6.3”) to yield reliable frequency based tension data. For V-belts<br />

the recommended minimum span length is about 30 times the belt top width.<br />

These are guidelines or rules of thumb that have evolved over time. It is the link between frequency<br />

and tension, as well as the optical signal that degrades as these minimums are approached. A<br />

practical test is to take several reading (from 3 to 5 repeats) under identical conditions. If the results<br />

vary wildly or if frequency exceeds 400Hz (top of <strong>Meter</strong> range) you need to select a longer span. If<br />

you have concerns about a specific drive, you should contact Goodyear Engineered Products’ Technical<br />

Support or your local Goodyear EP Distributor. Telephone or e-mail contact information for Goodyear EP’s<br />

Technical Support is given in the User Manual.<br />

What if I cannot access the top surface of the belt span selected? If the flat face of the belt is not<br />

accessible it may be possible to beam the sensor onto the edge of the belt to take your measurement.<br />

The inside surface (toothed side of a synchronous belt) is equally acceptable as a target for the<br />

sensor. Regardless of the surface selected, the best readings are obtained with the sensor held<br />

square to the target surface at a distance of 3/8”. In practice, valid readings have been taken at<br />

distances up to 2” and at angles varying from vertical to plus/minus 45 degrees.<br />

Does the sensor need to be aimed at the exact center of the span? Let specific drive conditions be<br />

your guide. Best shop practice is to take your reading as close to the span center as is practical.<br />

A strummed belt vibrates with the same frequency everywhere along the unsupported span. The<br />

amplitude of vibration is greatest in the center of the span, degrading geometrically as the tangent<br />

points (sprocket or pulley contacts) are approached. Bigger features are generally the easiest to see<br />

(think eye chart). The TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> is an optical system so the best reading is taken<br />

directly above the center of the span although, on most belts valid and accurate readings can be achieved<br />

almost anywhere along the belt span.<br />

24

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

Sometimes I have trouble getting a reading on a narrow belt such as a Torque Flex 4X, any<br />

suggestions? Best shop practice is to orient the sensor with the long edge of the sensor parallel to<br />

the centerline of the belt. There may be a slight difference in focus between the aiming LED and the<br />

infrared beam at the distance you happened to be holding the sensor. Orienting with the long edge<br />

parallel to the belt centerline simply provides a larger target area thus easing the need for very precise<br />

aiming. This suggestion also applies when taking measurements from the edge of a belt.<br />

What are some of the advantages of the new TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> over the older sonic<br />

meter? Accuracy, reliability and ease of use are the primary benefits of the TensionRite <strong>Belt</strong> <strong>Frequency</strong><br />

<strong>Meter</strong>. The accuracy of measurement is largely determined by the method of measurement. While both<br />

sonic and optical tension meters rely upon the same transverse vibration of string theory (think tuning a<br />

violin) to determine belt strand tension, the two methods differ in how the frequency of vibration (Hz) is<br />

actually determined.<br />

A sonic meter (also know as an acoustical meter) indirectly measures vibration. It predicts vibration<br />

frequency based upon sensing disturbances in the pressure of the air (essentially noise) adjacent to<br />

the belt. The sensor is really a specialized microphone. Ambient conditions are a critical factor.<br />

Background noise and air currents can and will affect the accuracy of this type sensor. Some sonic<br />

meters incorporate internal filters in an attempt to counter stray inputs while other units include a<br />

“gain” adjustment for the sensor.<br />

An optical meter directly measures belt vibration. Using advanced solid-state infra-red technology, the<br />

sensor actually “sees” the belt surface. Any displacement of the belt is observed and the frequency of<br />

displacement over time is measured. This method of direct measurement is unaffected by ambient<br />

conditions resulting in superior accuracy without the need for filters or manual tuning.<br />

If the meter uses an infra-red beam, what is the lighted spot I see on the belt? The orange lighted spot<br />

is generated by a narrow angle LED (Light Emitting Diode). It is focused to the same area as is the<br />

infrared generator and is to be used as an aiming guide for the invisible infrared beam.<br />

What about operator safety, isn’t an infrared beam really an invisible death ray? Don’t confuse the<br />

optical sensor with a laser. Lasers are intensifiers that project a coherent beam (parallel rays) with low<br />

divergence and high brightness. The result is a focused beam with very high energy density. The<br />

sensor of the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> uses the non-coherent infrared output of a small<br />

low-energy diode.<br />

Do I need to input span length and belt mass parameters each time the meter is used? Not<br />

necessarily. If you are dealing with a drive on a regular basis, the memory feature of the TensionRite <strong>Belt</strong><br />

<strong>Frequency</strong> <strong>Meter</strong> may be to your advantage. Up to three different sets of belt parameters can be stored in<br />

the meter, each assigned to one of the three “MEM” keys. The next time that particular drive is tensioned,<br />

pressing the appropriate key will recall and load the belt mass and span information.<br />

You can also eliminate completely the need for span and mass parameters by working directly with the<br />

belt vibration frequencies (f ) measured in hertz (Hz) rather than with belt tension values (expressed in<br />

units of force). Hz values are independent of mass and span values. The output of the MAXIMIZER <br />

program gives target Hz values in addition to traditional tension values. Armed with the correct Hz<br />

information simply follow the steps shown in the “Quick Start” section of the User Manual.<br />

25

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

How do I determine span length? There are three common methods to determine span length: using<br />

the output from the MAXIMIZER drive-analysis program, performing a mathematical calculation or by<br />

direct measurement.<br />

Goodyear Engineered Products’ user friendly drive analysis program, MAXIMIZER, will automatically report<br />

belt tensioning parameters (including span length) as part of your drive selection process. Or, you can<br />

make the calculation manually using the formula shown in the User Manual. You must know the center<br />

distance (dimension between shaft centers) as well as the diameter of both driveR and driveN to complete<br />

the calculation.<br />

The least accurate but sometimes most practical method to determine span length is by direct<br />

measurement. Span length is defined to be the length of the unsupported belt between the exit point<br />

of one pulley and the entry point of the adjacent pulley. Simply locate these two tangent points as<br />

best as you can and then measure between them along the back of the belt. The resulting<br />

measurement (expressed in meters) is your span length.<br />

Our company operating procedures require periodic calibration and certification of measuring tools.<br />

Are there such procedures for the TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong>? Yes there are. The solid-state<br />

circuitry of the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> is based upon a very stable quartz crystal which<br />

requires no adjustment. Included with your meter is a precision mechanical resonator (fancy term for<br />

a tuning fork) to allow a spot check at a frequency of 250Hz any time you wish. See section “Calibration”<br />

in the User Manual for a depiction of the procedure. Labeling the meter as a “Process Aid” coupled with<br />

performance of this spot check on a periodic basis might well satisfy your procedural requirements.<br />

If more rigorous documentation is required, the meter may be returned to the manufacturer at yearly<br />

intervals to have the calibration certified to NAMAS / UKAS (National Accreditation of Measurement<br />

and Sampling / United Kingdom Accreditation Standards). Such certification is generally acceptable<br />

for ISO9001. The manufacturer must be contacted for detailed return procedure prior to sending the<br />

meter. There will be a charge for this service. The section “Annual Certification” in the TensionRite<br />

User Manual gives contact information for the manufacturer.<br />

Will the meter work for other than Goodyear EP belt products? Yes, the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong><br />

will give accurate results for belts from other manufacturers. The frequency (Hz) measuring mode is<br />

immediately applicable. In order to harvest accurate tension values (in units of force rather<br />

than frequency) you must know the belt mass constant for your actual belt.<br />

How do I determine belt mass short of contacting a manufacturer? There is no secret to belt mass.<br />

It is defined as the unit weight of the belt or the linear belt mass and is expressed in kg/m. So simply<br />

weigh the belt on an accurate scale such as a postage scale, convert that weight to kilograms, then<br />

divide the result by the length of the belt expressed in meters. For example: say you have a generic<br />

synchronous belt of part number 1280 8M 50 (8mm pitch, 50mm wide, 1280mm long).<br />

Your postage scale says the belt weighs 9.9 ounces. Your calculations become:<br />

9.9 ounces x 0.02835kg per oz = 0.281kg (conversion constant from chart)<br />

1280mm x 0.001 = 1.28m (metric convention)<br />

0.281kg / 1.28m = 0.2195kg/m = round to = <strong>Belt</strong> Mass = 0.220kg/m<br />

This is the number to then input as <strong>Belt</strong> Mass.<br />

We are being asked to comply with some new environmental regulations called RoHS (Restrictions on<br />

Hazardous Substances). What is the status of the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> in relation to RoHS?<br />

The manufacturer of the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> states that they are in full compliance with the<br />

restricted materials listed in the Directive 2002/95/EC of the European Parliament and the Council of 27<br />

January 2003, commonly referred to as RoHS.<br />

26

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

Can the TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> be used with rechargeable batteries? The TensionRite <strong>Belt</strong><br />

<strong>Frequency</strong> <strong>Meter</strong> can be successfully energized with an array of any AA size batteries, either rechargeable<br />

or disposable. The meter does not feature recharging circuitry so the user must supply a separate battery<br />

charging station in order to use rechargeable batteries. A second set of batteries is also recommended to<br />

avoid leaving the meter without power while the batteries charge. Leaving the meter unenergized for longer<br />

than approximately 30 seconds will result in the loss of any stored data.<br />

May the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> continue to be used while on-board charging of the batteries is<br />

taking place or even when connected to the charger with batteries removed? In theory, maybe: in practice,<br />

no. A software block has been placed to prevent operation of the optical sensor while the batteries are<br />

under on-board charging.<br />

Most commercial charging units utilize only a rectifier for nominal smoothing of the output. The optical<br />

sensor requires a ripple free current supply. To preclude potential damage to the infrared circuitry and to<br />

eliminate the harvest of faulty data, the meter has been “taught” to display a charging indication (similar<br />

to the “low battery” signal) when turned on during a charging cycle. In addition, Goodyear Engineered<br />

Products strongly recommends that the sensor head be totally disconnected during the on-board battery<br />

charging process. Refer to Section 4.5 of this User Manual for further information.<br />

Will tramp IR signals from other systems affect the operation of the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong>?<br />

The answer is a definite no. The amount of environmental IR reaching the sensor (which has a narrow<br />

beam of only 15 degrees) is very small when compared with the IR signal from the sensor emitter that is<br />

reflected from the belt. In addition, the meter uses a technique called “synchronous demodulation” to<br />

recover the reflected belt signal while rejecting all external signals not modulated in synchrony with<br />

the meter.<br />

Will tramp signals from the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> affect other equipment using IR<br />

communication? It is not possible to give a definitive universal statement on this topic. It depends<br />

primarily upon the quality of the third party equipment. Again, the narrow beam in addition to the very low<br />

energy of that focused beam make it highly unlikely that the signal from the TensionRite <strong>Belt</strong> <strong>Frequency</strong><br />

<strong>Meter</strong> will interact with any other device. If this is a concern in your location, a carefully controlled trial<br />

is suggested prior to releasing the device for general use in your facility.<br />

Is the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> rated as intrinsically safe as defined by International Standard<br />

IEC 60079-11? The TensionRite <strong>Meter</strong> does not qualify for I.S. certification. As such, the meter is not to<br />

be used in locations with potentially explosive atmospheres. The meter circuitry generally complies with<br />

the technical requirements of the standards. However, the meter housing will not pass scrutiny. The ease<br />

in which the batteries could, in some circumstances, fall free and thus have no current/power limit<br />

protection prevents the housing from qualifying for I.S. certification.<br />

27

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

Appendix<br />

4.0 Tensioning Tables<br />

Synchronous <strong>Belt</strong> Tensioning Tables<br />

Eagle Pd<br />

Falcon Pd<br />

Blackhawk Pd<br />

Hawk Pd<br />

<strong>Belt</strong> Type<br />

<strong>Belt</strong> Strand Tension (lbs.)<br />

0-100 RPM 101-1000 RPM 1000-up RPM <strong>Belt</strong><br />

NEW USED NEW USED NEW USED Weight<br />

BELT BELT BELT BELT BELT BELT (kg/m)<br />

Yellow 224 160 176 112 128 96 0.071<br />

White 449 305 353 241 273 177 0.142<br />

Purple 897 625 689 481 545 369 0.283<br />

Blue 817 561 657 449 561 385 0.254<br />

Green 1210 842 986 682 842 586 0.380<br />

Orange 1618 1122 1314 914 1122 786 0.507<br />

Red 2436 1700 1956 1364 1700 1172 0.761<br />

8GTR 12 370 258 210 146 130 98 0.064<br />

8GTR 21 648 456 376 264 232 168 0.112<br />

8GTR 36 1111 775 631 439 391 295 0.192<br />

8GTR 62 1913 1337 1081 761 681 505 0.330<br />

14GTR 20 571 427 459 331 411 299 0.163<br />

14GTR 37 1052 796 844 620 764 556 0.301<br />

14GTR 68 1939 1459 1555 1123 1395 1011 0.550<br />

14GTR 90 2570 1930 2074 1498 1850 1354 0.738<br />

14GTR 125 3578 2666 2874 2074 2570 1866 1.023<br />

8MBH 12 179 131 131 99 99 67 0.045<br />

8MBH 22 345 249 233 169 185 137 0.069<br />

8MBH 35 539 379 379 267 299 219 0.159<br />

8MBH 60 928 656 656 464 512 368 0.226<br />

14MBH 20 553 393 409 297 345 249 0.164<br />

14MBH 42 1167 831 863 623 735 527 0.344<br />

14MBH 65 1796 1284 1348 964 1140 804 0.532<br />

14MBH 90 2487 1783 1863 1335 1575 1127 0.737<br />

14MBH 120 3332 2372 2484 1764 2084 1492 0.983<br />

8M 20 226 162 194 146 178 130 0.118<br />

8M 30 347 251 299 219 283 203 0.176<br />

8M 50 590 430 526 382 478 350 0.289<br />

8M 85 1046 742 918 662 838 598 0.507<br />

14M 40 715 507 571 411 475 347 0.438<br />

14M 55 1069 765 845 605 717 509 0.583<br />

14M 85 1778 1266 1410 1010 1186 850 0.913<br />

14M 115 2486 1782 1974 1414 1654 1174 1.233<br />

14M 170 3827 2739 3059 2179 2579 1843 1.835<br />

Eagle Pd<br />

Falcon Pd<br />

Blackhawk Pd<br />

Hawk Pd<br />

Deflection Forces for <strong>Belt</strong> Tensioning (lbs.)<br />

<strong>Belt</strong> Type<br />

0-100 RPM 101-1000 RPM 1000-up RPM<br />

NEW<br />

BELT<br />

USED<br />

BELT<br />

NEW<br />

BELT<br />

USED<br />

BELT<br />

NEW<br />

BELT<br />

USED<br />

BELT<br />

Yellow 15 11 12 8 9 7<br />

White 30 21 24 17 19 13<br />

Purple 60 43 47 34 38 27<br />

Blue 54 38 44 31 38 27<br />

Green 80 57 66 47 57 41<br />

Orange 107 76 88 63 76 55<br />

Red 161 115 131 94 115 82<br />

8GTR 12 24 17 14 10 9 7<br />

8GTR 21 42 30 25 18 16 12<br />

8GTR 36 72 51 42 30 27 21<br />

8GTR 62 124 88 72 52 47 36<br />

14GTR 20 38 29 31 23 28 21<br />

14GTR 37 70 54 57 43 52 39<br />

14GTR 68 129 99 105 78 95 71<br />

14GTR 90 171 131 140 104 126 95<br />

14GTR 125 238 181 194 144 175 131<br />

8MBH 12 12 9 9 7 7 5<br />

8MBH 22 23 17 16 12 13 10<br />

8MBH 35 36 26 26 19 21 16<br />

8MBH 60 62 45 45 33 36 27<br />

14MBH 20 36 26 27 20 23 17<br />

14MBH 42 76 55 57 42 49 36<br />

14MBH 65 117 85 89 65 76 55<br />

14MBH 90 162 118 123 90 105 77<br />

14MBH 120 217 157 164 119 139 102<br />

8M 20 15 11 13 10 12 9<br />

8M 30 23 17 20 15 19 14<br />

8M 50 39 29 35 26 32 24<br />

8M 85 69 50 61 45 56 41<br />

14M 40 47 34 38 28 32 24<br />

14M 55 70 51 56 41 48 35<br />

14M 85 116 84 93 68 79 58<br />

14M 115 162 118 130 95 110 80<br />

14M 170 249 181 201 146 171 125<br />

1. The table deflection forces and strand tensions are typically at maximum values to cover the broad range of loads, RPM and pulley combinations for all possible drives.<br />

2. For drives where hub loads are critical, high speed drives or other drives with special circumstances, the belt deflection force and strand installation tension should be<br />

calculated by using formulas found in existing Engineering Manuals or use the Maximizer Drive Selection Analysis Program.<br />

3. Consult the TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> manual for detailed information on using the frequency based tension gauge.<br />

4. Goodyear Engineered Products offers three different levels of tension gauges to aid you in properly tensioning your power transmission belts. See your Goodyear EP<br />

sales representative or your local authorized Goodyear EP Power Transmission distributor for more information on the Goodyear EP tensioning gauges.<br />

28

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

4.0 Tensioning Tables<br />

V-<strong>Belt</strong> Tensioning Tables<br />

Deflection Forces for <strong>Belt</strong> Tensioning (lbs.)<br />

<strong>Belt</strong> Strand Tension (lbs.)<br />

Cross Section<br />

A, AX<br />

B, BX<br />

C, CX<br />

D<br />

3V, 3VX,<br />

XPZ<br />

SPA, XPA<br />

5V, 5VX,<br />

SPB, XPB<br />

SPC,<br />

XPC<br />

8V<br />

5VF<br />

8VF<br />

Smallest<br />

Sheave<br />

Diameter<br />

Range<br />

3.0 - 3.6<br />

3.8 - 4.8<br />

5.0 - 7.0<br />

3.4 - 4.2<br />

4.4 - 5.6<br />

5.8 - 8.6<br />

7.0 - 9.0<br />

9.5 - 16.0<br />

12.0 - 16.0<br />

18.0 - 20.0<br />

2.2 - 2.4<br />

2.65 - 3.65<br />

4.12 - 6.90<br />

3.0 - 4.1<br />

4.2 - 5.7<br />

5.7 - 10.1<br />

4.4 - 6.7<br />

7.1 - 10.9<br />

11.8 - 16.0<br />

8.3 - 14.3<br />

14.4 - 20.1<br />

12.5 - 17.0<br />

18.0 - 22.4<br />

7.1 - 10.9<br />

11.8 - 16.0<br />

12.5 - 20.0<br />

21.2 - 25.0<br />

RPM Range<br />

Noncogged Single,<br />

Torque Team* & Torque<br />

Team Plus* <strong>Belt</strong>s<br />

NEW<br />

BELT<br />

USED<br />

BELT<br />

Cogged Single &<br />

Torque Team*<br />

NEW<br />

BELT<br />

USED<br />

BELT<br />

1000 - 2500 5.5 3.7 6.1 4.1<br />

2501 - 4000 4.2 2.8 5.0 3.4<br />

1000 - 2500 6.8 4.5 7.4 5.0<br />

2501 - 4000 5.7 3.8 6.4 4.3<br />

1000 - 2500 8.0 5.4 9.4 5.7<br />

2501 - 4000 7.0 4.7 7.6 5.1<br />

860 - 2500 N/A N/A 7.2 4.9<br />

2501 - 4000 N/A N/A 6.2 4.2<br />

860 - 2500 7.9 5.3 10.5 7.1<br />

2501 - 4000 6.7 4.5 9.1 6.2<br />

860 - 2500 9.4 6.3 12.6 8.5<br />

2501 - 4000 8.2 5.5 10.9 7.3<br />

500 - 1740 17.0 11.5 21.8 14.7<br />

1741 - 3000 13.8 9.4 17.5 11.9<br />

500 - 1740 21.0 14.1 23.5 15.9<br />

1741 - 3000 18.5 12.5 21.6 14.6<br />

200 - 850 37.0 24.9 N/A N/A<br />

851 - 1500 31.3 21.2 N/A N/A<br />

200 - 850 45.2 30.4 N/A N/A<br />

851 - 1500 38.0 25.6 N/A N/A<br />

1000 - 2500 N/A N/A 4.9 3.3<br />

2501 - 4000 N/A N/A 4.3 2.9<br />

1000 - 2500 5.1 3.6 6.2 4.2<br />

2501 - 4000 4.4 3.0 5.6 3.8<br />

1000 - 2500 7.3 4.9 7.9 5.3<br />

2501 - 4000 6.6 4.4 7.3 4.9<br />

1000 - 2500 N/A N/A 9.0 6.1<br />

2501 - 4000 N/A N/A 7.9 5.2<br />

1000 - 2500 10.1 6.7 12.4 8.3<br />

2501 - 4000 8.3 5.6 11.2 7.4<br />

1000 - 2500 14.6 9.7 15.3 10.1<br />

2501 - 4000 12.6 8.5 13.7 9.2<br />

500 - 1749 N/A N/A 15.2 10.2<br />

1750 - 3000 N/A N/A 13.2 8.8<br />

3001 - 4000 N/A N/A 8.5 5.6<br />

500 - 1740 18.9 12.7 22.1 14.8<br />

1741 - 3000 16.7 11.2 20.1 13.7<br />

500 - 1740 23.4 15.5 25.5 17.1<br />

1741 - 3000 21.8 14.6 25.0 16.8<br />

500 - 1000 31.0 20.7 33.3 22.3<br />

1000 - 1750 28.6 19.1 32.4 21.6<br />

500 - 1000 39.3 26.3 41.8 27.9<br />

1000 - 1750 37.5 25.2 45.6 30.3<br />

200 - 850 49.3 33.0 N/A N/A<br />

851 - 1500 39.9 26.8 N/A N/A<br />

200 - 850 59.2 39.6 N/A N/A<br />

851 - 1500 52.7 35.3 N/A N/A<br />

200 - 700 30.9 21.1 N/A N/A<br />

701 - 1250 26.3 18.0 N/A N/A<br />

1251 - 1900 23.4 16.7 N/A N/A<br />

1901 - 3000 23.0 15.8 N/A N/A<br />

200 - 700 39.5 26.8 N/A N/A<br />

701 - 1250 34.7 23.5 N/A N/A<br />

1251 - 2100 33.3 22.7 N/A N/A<br />

200 - 500 65.8 44.7 N/A N/A<br />

501 - 850 56.6 38.5 N/A N/A<br />

851 - 1150 51.6 35.2 N/A N/A<br />

1151 - 1650 49.0 33.5 N/A N/A<br />

200 - 500 97.6 65.9 N/A N/A<br />

501 - 850 90.6 61.2 N/A N/A<br />

851 - 1200 84.3 57.0 N/A N/A<br />

Cross Section<br />

A, AX<br />

B, BX<br />

C, CX<br />

D<br />

3V, 3VX,<br />

XPZ<br />

SPA, XPA<br />

5V, 5VX,<br />

SPB, XPB<br />

SPC,<br />

XPC<br />

8V<br />

5VF<br />

8VF<br />

Smallest<br />

Sheave<br />

Diameter<br />

Range<br />

3.0 - 3.6<br />

3.8 - 4.8<br />

5.0 - 7.0<br />

12.5 - 17.0<br />

18.0 - 22.4<br />

7.1 - 10.9<br />

11.8 - 16.0<br />

12.5 - 20.0<br />

21.2 - 25.0<br />

RPM Range<br />

Noncogged Single,<br />

Torque Team* &<br />

Torque Team Plus*<br />

<strong>Belt</strong>s<br />

NEW<br />

BELT<br />

USED<br />

BELT<br />

Cogged Single &<br />

Torque Team*<br />

NEW<br />

BELT<br />

USED<br />

BELT<br />

<strong>Belt</strong><br />

Weight<br />

(kg/meter)<br />

1000 - 2500 84 56 94 62<br />

2501 - 4000 64 41 76 51 A = 0.100<br />

1000 - 2500 105 68 115 76<br />

2501 - 4000 88 57 99 65<br />

1000 - 2500 124 83 147 88 AX = 0.080<br />

2501 - 4000 108 72 118 78<br />

3.4 - 4.2<br />

860 - 2500 N/A N/A 110.3 73.5 B = 0.162<br />

2501 - 4000 N/A N/A 94.3 62.3 Torque Team<br />

4.4 - 5.6<br />

860 - 2500 121.5 79.9 163.1 108.7 B = 0.216 x # ribs<br />

2501 - 4000 102.3 67.1 140.7 94.3 BX = 0.161<br />

5.8 - 8.6<br />

860 - 2500 145.5 95.9 196.7 131.1 Torque Team<br />

2501 - 4000 126.3 83.1 169.5 111.9 BX = 0.213 x # ribs<br />

7.0 - 9.0<br />

500 - 1740 264.6 176.6 341.4 227.8 C = 0.296<br />

Torque Team<br />

1741 - 3000 213.4 143.0 272.6 183.0 C = 0.367 x # ribs<br />

9.5 - 16.0<br />

500 - 1740 328.6 218.2 368.6 247.0 CX = 0.290<br />

Torque Team<br />

1741 - 3000 288.6 192.6 338.2 226.2 CX = 0.344 x # ribs<br />

12.0 - 16.0<br />

200 - 850 581.9 388.3 N/A N/A<br />

D = 0.671<br />

851 - 1500 490.7 329.1 N/A N/A<br />

18.0 - 20.0<br />

200 - 850 713.1 476.3 N/A N/A Torque Team<br />

851 - 1500 597.9 399.5 N/A N/A D = 0.755 x # ribs<br />

2.2 - 2.4<br />

1000 - 2500 N/A N/A 75.9 50.3<br />

2501 - 4000 N/A N/A 66.3 43.9 3V = 0.086<br />

2.65 - 3.65<br />

1000 - 2500 79.1 55.1 96.7 64.7<br />

2501 - 4000 67.9 45.5 87.1 58.3 3VX, XPZ = 0.073<br />

4.12 - 6.90<br />

1000 - 2500 114.3 75.9 123.9 82.3 Torque Team<br />

2501 - 4000 103.1 67.9 114.3 75.9 3VX = 0.096 x # ribs<br />

3.0 - 4.1<br />

1000 - 2500 N/A N/A 140.3 93.9<br />

2501 - 4000 N/A N/A 122.7 79.5 SPA = 0.155<br />

4.2 - 5.7<br />

1000 - 2500 157.9 103.5 194.7 129.1<br />

2501 - 4000 129.1 85.9 175.5 114.7<br />

5.7 - 10.1<br />

1000 - 2500 229.9 151.5 241.1 157.9 XPA= 0.127<br />

2501 - 4000 197.9 132.3 215.5 143.5<br />

500 - 1749 N/A N/A 238.8 158.8 5V, SPB = 0.207<br />

4.4 - 6.7 1750 - 3000 N/A N/A 206.8 136.4 Torque Team<br />

3001 - 4000 N/A N/A 131.6 85.2 5V = 0.249 x # ribs<br />

7.1 - 10.9<br />

500 - 1740 298.0 198.8 349.2 232.4<br />

5VX, XPB = 0.169<br />

1741 - 3000 262.8 174.8 317.2 214.8<br />

11.8 - 16.0<br />

500 - 1740 370.0 243.6 403.6 269.2 Torque Team<br />

1741 - 3000 344.4 229.2 395.6 264.4 5VX = 0.217 x # ribs<br />

8.3 - 14.3<br />

500 - 1000 488.6 323.8 525.4 349.4<br />

SPC = 0..353<br />

1000 - 1750 450.2 298.2 511.0 338.2<br />

14.4 - 20.1<br />

500 - 1000 621.4 413.4 661.4 439.0<br />

XPC = 0..289<br />

1000 - 1750 592.6 395.8 722.2 477.4<br />

200 - 850 779.3 518.5 N/A N/A<br />

8V = 0.581<br />

851 - 1500 628.9 419.3 N/A N/A<br />

200 - 850 937.7 624.1 N/A N/A Torque Team<br />

851 - 1500 833.7 555.3 N/A N/A 8V = 0.598 x # ribs<br />

200 - 700 467.1 310.3 N/A N/A<br />

701 - 1250 393.5 260.7 N/A N/A<br />

1251 - 1900 347.1 239.9 N/A N/A Torque Team<br />

1901 - 3000 340.7 225.5 N/A N/A 5VF = 0.242 x # of ribs<br />

200 - 700 604.7 401.5 N/A N/A<br />

701 - 1250 527.9 348.7 N/A N/A<br />

1251 - 2100 505.5 335.9 N/A N/A<br />

200 - 500 1008.4 670.8 N/A N/A<br />

501 - 850 861.2 571.6 N/A N/A<br />

851 - 1150 781.2 518.8 N/A N/A Torque Team<br />

1151 - 1650 739.6 491.6 N/A N/A 8VF = 0.615 x # of ribs<br />

200 - 500 1517.2 1010.0 N/A N/A<br />

501 - 850 1405.2 934.8 N/A N/A<br />

851 - 1200 1304.4 867.6 N/A N/A<br />

*Multiply table values by the number of torque team ribs to achieve recommended tensioning value.<br />

1. The table deflection forces and strand tensions are typically at maximum values to cover the broad range of loads, RPM and pulley combinations for all possible drives.<br />

2. For drives where hub loads are critical, high speed drives or other drives with special circumstances, the belt deflection force and strand installation tension should be<br />

calculated by using formulas found in existing Engineering Manuals or use the Maximizer Drive Selection Analysis Program.<br />

3. Consult the TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> manual for detailed information on using the frequency based tension gauge.<br />

4. Goodyear Engineered Products offers three different levels of tension gauges to aid you in properly tensioning your power transmission belts. See your Goodyear EP<br />

sales representative or your local authorized Goodyear EP Power Transmission distributor for more information on the Goodyear EP tensioning gauges.<br />

29

T e n s i o n R i t e ®<br />

B e l t f r e q u e n c y M e t e r<br />

Appendix<br />

5.0 Limited Warranty<br />

Limited Warranty Time of warranty is 12 months from date of original purchase provided that proper product<br />

registration has been completed. Product registration may be completed online at:<br />

www.clavis.co.uk/gytensionritemeter.<br />

Warranty covers defects in materials and workmanship for the device only. Warranty does not cover accessory items such as<br />

batteries and applies only to parts that were not damaged as a result of inappropriate handling or use. The warranty expires<br />

immediately if the device itself is opened.<br />

Unit must be returned to Integrated Display Systems Limited (IDS, also known as Clavis) for evaluation of all warranty<br />

claims. Any TensionRite ® <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong> claimed to have a covered warranty condition involving material or<br />

workmanship shall, upon Clavis’s approval, be returned to Clavis as designated, at the Customer’s expense. Under no<br />

circumstances will liability exceed the original purchase price of the meter. Clavis reserves the right to repair or replace<br />

the unit or to refund the original purchase price at their sole option.<br />

Limitation of Warranty: Veyance <strong>Technologies</strong>, Inc. and its affiliates exclude any further liability for software, handbooks<br />

and information material. Furthermore, Veyance <strong>Technologies</strong> does not accept liability for damages resulting from the use<br />

of the TensionRite <strong>Belt</strong> <strong>Frequency</strong> <strong>Meter</strong>.<br />

Veyance <strong>Technologies</strong>’s TOTAL RESPONSIBILITY AND LIABILITY FOR ANY AND ALL CLAIMS, LOSSES AND<br />

DAMAGES OF ANY KIND WHATSOEVER ARISING OUT OF ANY CAUSE WHATSOEVER (WHETHER UNDER ANY<br />

WARRANTY OR BASED IN CONTRACT, NEGLIGENCE, OTHER TORT, STRICT LIABILITY, BREACH OF WARRANTY,<br />

OTHER THEORY OR OTHERWISE) SHALL NOT EXCEED THE ORIGINAL PURCHASE PRICE OF THE TENSIONRITE<br />

BELT FREQUENCY METER IN RESPECT TO WHICH SUCH CAUSE ARISES, AND IN NO EVENT SHALL Veyance<br />

<strong>Technologies</strong> BE LIABLE FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL, EXAMPLARY, OR PUNITIVE DAMAGES<br />

RESULTING FROM ANY SUCH CAUSE. NO EMPLOYEE, AGENT AND/OR REPRESENTATIVE HAS AUTHORITY TO MAKE<br />

ANY REPRESENTATION, PROMISE OR AGREEMENT, EXCEPT AS STATED HEREIN. Veyance <strong>Technologies</strong> SHALL<br />

NOT BE LIABLE FOR, AND CUSTOMER ASSUMES ALL LIABILITY FOR, ALL PERSONAL INJURY AND PROPERTY<br />

DAMAGE CONNECTED WITH THE USE OF THE PRODUCT. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND<br />

THE DESCRIPTION ON THE FACE HEREOF, AND Veyance <strong>Technologies</strong> DISCLAIMS WARRANTY OF FITNESS FOR<br />

PURPOSE OR ANY OTHER IMPLIED WARRANTIES.<br />

Notice:<br />

All rights, especially for copying and distribution as well as translation of this material are reserved, and require written<br />

consent from Veyance <strong>Technologies</strong>, Inc. Goodyear Engineered Products are manufactured and sourced exclusively by<br />

Veyance <strong>Technologies</strong>, Inc. or its affiliates.<br />

Goodyear Engineered Products Customer Service<br />

800-235-4632<br />

www.goodyearep.com/ptp<br />

Integrated Display Systems Limited (Clavis)<br />

Tel: +44 (0) 191 2627869<br />

Fax: +44 (0) 191 2620091<br />

www.clavis.co.uk/gytensionritemeter<br />

Information you will need to register warranty online<br />

(keep log for your records)<br />

Date of Purchase______________________________________________________________________________<br />

Serial Number (on back of unit)__________________________________________________________________<br />

Purchaser’s Name______________________________________________________________________________<br />

Purchasers’ Mailing Address_____________________________________________________________________<br />

_____________________________________________________________________________________________<br />

City______________________________________________ State_________ Country_____________________<br />

E-mail (optional)_______________________________________________________________________________<br />