Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

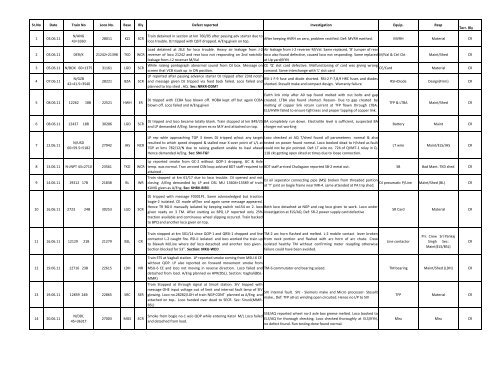

Sr.No Date Train No Loco No. Base Rly Defect reported Investigation Equip. Resp<br />

Terr. Rly<br />

1 03.06.11<br />

N/ANG<br />

43=3360<br />

28011 KZJ SCR<br />

Train detained in section at km 760/05 after passing adv starter due to<br />

After keeping HVRH on zero, problem rectified. Def: MVRH earthed. MVRH Material CR<br />

loco trouble. DJ tripped with QSIT dropped. A/Eng given on top.<br />

2 03.06.11 DER/K 21242+21398 TKD WCR<br />

Load detained at JSLE for loco trouble. Heavy air leakage from J‐2 Air leakage from J‐2 reverser M/Val. Same replaced. 'B' Jumper of rear<br />

reverser of loco 21242 and rear loco not responding on 2nd notchAir loco also found defective, caused loco not responding. Same replaced M/Val & Ctrl Ckt Maint/Shed CR<br />

leakage from J‐2 reverser M/Val<br />

at Up yard/KYN<br />

3 05.06.11 N/BOX 60=1375 31161 LGD SCR<br />

While raising pantograph abnormal sound from DJ box. Message on CE 'Q' slot card defective. Malfunctioning of card was giving wrong<br />

CE/Card<br />

screen that VCB stuck up in ON position.<br />

comand. Same interchange with 'L' slot card<br />

Material CR<br />

4 07.06.11<br />

LP reported after passing advance starter DJ tripped after 23rd notch<br />

N/GZB<br />

RSI‐1 F‐9 fuse and diode shorted. RSI‐2 F‐7,8,9 HRC fuses and diodes<br />

28221 BZA SCR and message given DJ tripped via feed back failed. Loco failed and<br />

42=41.5=3540<br />

shorted. Stesalit make and compact design. Warranty failure<br />

planned to trip shed , AQ. Sec: NRKR‐DDMT<br />

RSI+Diode Design(Firm) CR<br />

5 08.06.11 12262 18B 22521 HWH ER<br />

6 08.06.11 12437 18B 30286 LGD SCR<br />

DJ tripped with CCBA fuse blown off. HOBA kept off but again CCBA<br />

blown off. Loco failed and A/Eng given<br />

Earth link strip after A0 tap found melted with nut bolts and gap<br />

created. LTBA also found shorted. Reason‐ Due to gap created by<br />

melting of copper link return current at TFP flown through LTBA.<br />

ELS/HWH failed to ensure tightness and proper tapping of copper link.<br />

DJ tripped and loco became totally blank. Train stopped at km 849/25 BA completely run down. Electrolite level is sufficient, suspected BA<br />

and LP demanded A/Eng. Same given ex ex MJY and attached on top. charger not working<br />

TFP & LTBA Maint/Shed CR<br />

Battery Maint CR<br />

7 12.06.11<br />

N/USD<br />

60=59.5=5182<br />

27942 JHS NCR<br />

LP rep whle approaching TGP 3 times DJ tripped w/out any target Loco checked at AQ T/shed found all parameteers normal & also<br />

resulted to which speed dropped & stalled near X‐over point of L/L at tested on power found normal. Loco booked dead to H/shed as fault<br />

TGP at kms 782/12/N due to raising gradient unable to haul ahead could not be pin pointed. Def: LT wire no. 724 of QVMT‐1 relay in Q‐<br />

Hence demanded A/Eng. Sec: SNI‐TGP<br />

118 ckt getting open ckted at times due to loose connection.<br />

LT wire Maint/ELS/JHS CR<br />

8 13.06.11 N‐JNPT 43=2710 23561 TKD WCR<br />

Lp reported smoke from GC‐2 without QOP‐1 droppng. GC & Axle<br />

temp. was normal. Tran arrcved CSN loop advised BDT staff required to BDT staff arrived Chalisgaon reported SB‐2 metal out. SB Bad Mant. TKD shed CR<br />

attained .<br />

9 14.06.11 19312 17B 21838 BL WR<br />

Train stopped at km 61/17 due to loco trouble. DJ opened and not<br />

DJ oil seperator connecting pipe (MS) broken from threaded portion<br />

closing A/Eng demanded by LP and DSL MU 13604+13589 of train<br />

DJ pneumatic P/Line<br />

at 'T' joint on bogie frame near MR‐4. same attended at PA trip shed.<br />

KLMG given as A/Eng. Sec: KHBV‐BIRD<br />

Maint/Shed (BL) CR<br />

10 16.06.11 2723 24B 30253 LGD SCR<br />

DJ tripped with message F0301P1. Same acknowledged but traction<br />

bogie‐2 isolated. CE made off/on and again same message appeared.<br />

Hence TR BG‐II manually isolated by keeping switch no154 on 2. loco Both loco detached at NGP and cog loco given to work. Loco under<br />

given ready on 3 TM. After starting ex BPQ LP reported only 25% investigation at ELS/AQ. Def: SR‐2 power supply card defective<br />

traction available and continuous wheel slipping occured. Train backed<br />

to BPQ and another loco given on top.<br />

SR Card Material CR<br />

11 16.06.11 12129 21B 21279 BSL CR<br />

Train stopped at km 501/14 since QOP‐1 and QRSI‐1 dropped and line TM‐2 arc horn flashed and melted. L‐2 mobile contact lever broken<br />

contactor L‐2 caught fire. RSI‐II isolated and loco worked the train up from neck portion and flashed with arc horn of arc chute. Crew<br />

to Biswah M/Line where def loco detached and another loco given.. isolated healthy TM without confirming meter reaqding otherwise<br />

Section blocked for 53". Section: MKU‐WDD<br />

failure could have been avoided.<br />

Line contactor<br />

Pri: Crew Sri Pankaj<br />

Singh Sec:<br />

Maint(ELS/BSL)<br />

CR<br />

12 19.06.11 12716 23B 22615 LDH NR<br />

13 19.06.11 12859 24B 22865 SRC SER<br />

Train STS at Vaghali station. LP reported smoke coming from MSU‐6 CE<br />

without QOP. LP also reported on forward movement smoke from<br />

MSU‐6 CE and loco not moving in reverse direction. Loco failed and TM‐6 commutator end bearing seized. TM bearing Maint/Shed (LDH) CR<br />

detached from load. A/Eng planned ex HPR(DSL). Section: Vaghali(BSL‐<br />

MMR)<br />

Train Stopped at through signal at Sirsoli station. SIV tripped with<br />

message OHE input voltage out of limit and internal fault lamp of SIV<br />

SIV internal fault. SIV ‐ Siemens make and Micro processor‐ Stesalit<br />

glowing. Loco no.28282/LDH of train NGP CONT planned as A/Eng and<br />

make.. Def: TFP a0‐a1 winding open circuited. Hence no I/P to SIV<br />

attached on top.. Loco handed over dead to SECR. Sec: Sirsoli(MMR‐<br />

BSL)<br />

TFP Material CR<br />

14 20.06.11<br />

N/DDL<br />

45=3631T<br />

27003 MGS ECR<br />

SSE/AQ reported wheel no‐3 axle box greese melted. Loco booked to<br />

Smoke from bogie no‐1 w/o QOP while entering Katol M/L Loco failed<br />

ELS/AQ for thorough checking. Loco checked thoroughly at ELS/KYN,<br />

and detached from load.<br />

no defect found. Run testing done found normal.<br />

Misc Misc CR

15 21.06.11 11071 18B 21931 KYN CR<br />

16 21.06.11 12810 24B 22879 SRC SER<br />

DS tripped with converter faulty and train stopped at km 51/01. train F‐3 fuse blown off since GTO shorted. Original GTO received with SI<br />

engine of N‐NGSM(DSL) at KYN given as A/Eng<br />

unit of 1997 make.<br />

QOP‐1, QRSI‐1 and QLM dropped and smoke from HT compartment CTF‐1 contact flashed , its commom bus bar insulation burnt. TM‐1,2<br />

near RSI‐1. Train backed to GAO after isolating RSI‐1. Loco failed and and 3 IR value zero. Firm has been advised to attend the loco.<br />

another loco given<br />

Warranty failure<br />

17 24.06.11 12138 22701 BRC WR<br />

Train stopped after passing starter signal at Dongargaon & then backed<br />

to DGN main line. LP rep while approaching DGN H/signal QOP‐2 , QRSI‐Loco became normal after isolating TM‐6 & worked 5 TM upto IGP.<br />

2 dropped, tried by isolating TM‐4,5 & 6 one by one but not succeed. TM‐6 badly flashed and IR value found '0'. TM‐6 isolated and given fit<br />

HQOP‐2 kept OFF but smoke noticed from under truck. Same loco on 5 TM. Crew took more time to isolate def TM<br />

worked further on 5 TM.<br />

LP reported train stopped at km 785/7, FO702P1 auxilary convertor‐2<br />

18 27.06.11 N‐KNW 43=3831 31278 AQ CR<br />

isolated and also bogie‐1 isolated Due to rising gradient train stopped. In Traction converter no‐1 MPH incomming cable no. 1134 from SB<br />

Train backed to Wagholi on 3 TM and then failed. Section blocked for board(BUR O/P cable) parted from lug due to poor crimping by CLW.<br />

1'11".<br />

19 29.06.11<br />

Smoke noticed from under track w/o QOP target. Driver stopped the TM‐5 deflector came out. This is initial stage of TM bearing seizure<br />

N/BDI<br />

27685 LDH NR train to check loco and rfound burning smell near TM‐5. loco detached case. Pinion removed and loco will will be given fit on 5 TM for<br />

60=59.5=5325<br />

and placed in siding.<br />

H/Shed<br />

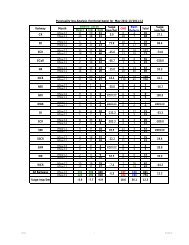

1 01.06.11 MTPS 27821+ 27819 BIA SECR Rear loco no 27821 suddenly tripped & not energised due to SIV not M/Staff Mr. S.C.Gorai + LI/UDL M.Roy reported SIV not pick up after<br />

pick up.<br />

pressing BLRDJ 30 Sec.M/staff & LI escorted the rear loco to clean the<br />

load by pressing BLRDJ. Again rear loco tripped & notch not<br />

progressing by manual control also. Banking loco attached on rear &<br />

clear the section SMGR type ‐ ABB<br />

2 02.06.11 2307 UP 22863 HWH ER Train stopped at Km 249/19 due to DJ trip. Message given “ DJ trip via<br />

DJ feed back failure.<br />

3 12.06.11 EC/ BAD 23754 GZB NR After passing CRJ Starter signal loco trip through QOA. On checking<br />

found S/E from MVRH.<br />

4 17.06.11 EC/TNEB 27372 NKJ WCR After passing 'N' sec between KQU‐BRPA while closing DJ loco tripped<br />

through QOA & QOA(P).<br />

5 19.06.11 12988 22071 GZB NR Loco trip through QOA (P) LP isolated HQOA but found all auxiliary not<br />

working. On checking found CCA was melting. LP isolated HOBA &<br />

worked the train up to SDAH.<br />

6 20.06.11 18616 DN 22271 SRC SER Train detained at KAN (8:32 – 9:09 hrs) due to pressure trouble.<br />

Arrived BWN by manual control.<br />

7 20.06.11 12340 DN 22752 MGS ECR After start RNG MVRH abnormal sound. Then HVRH Pos ‘0’ & arrived at<br />

UDL by 5 th notch. LI & M/staff checked & found MVRH impeller<br />

broken.<br />

8 24.06.11 6310 DN 22327 HWH ER Train stopped in bet TTN‐JSME due to BP pressure dropped. On<br />

checking found Both CP not working.<br />

1 1‐Jun‐11 2839 22368 SRC SER Train JEN through passed at 5.15 hrs and stopped at Km no 357/10 due<br />

to TLTE on run at 5.22 hrs. On checking found GR not progressing with<br />

LSB glowing. On checking LP found CTF‐3 automatically goes to braking<br />

condition even if MP on "0". So LP tied CTF‐3 on traction position and<br />

started the train at 5.45 hrs.<br />

2 1‐Jun‐11 E/MGPV‐37 27606 NKJ WCR LP informed at 6.00 hrs from JKPR that GR not progressing. On<br />

checking he found SMGR pressure showing 9.0 Kg/Cm2. Same was<br />

informed to TLC/KUR & suspecting trouble in SMGR reducing valve,<br />

message given to ELS/ANGL for supplying of the same. But due to<br />

unavailability of SMGR reducing Valve loco directed to ELS/VSKP after<br />

marking TR .<br />

On checking found at HWH shed MPCS (Steslite) unit defective,<br />

changed by firm<br />

LI Ram Babu gone to site reported that S/E from MVRH. Loco checked<br />

at ASN shed & found S/E from MVRH .Loco sent to base shed<br />

CLI/B.K.Saha Roy /BWN & JE/BWN Manas Chakraborty arrived at BRPA<br />

on checking found no fire extinguisher used, there was no roof<br />

leakage.HVSL1,HVSL2,HPH competely burnt condition, suspected sort<br />

circuit.Loco sent to base shed.<br />

On checking at NKG found RPQOA resistance burnt.CCA melted due to<br />

wire no.420 in bet SB‐1 (Cab1) panel to SB2 (Cab2) panel bonded.<br />

QOA permanent TFWA meggaring value of a 0 & a 1 bushing is<br />

showing<br />

JE/BWN Bhowmik checked the loco & found after cooler pipe crack.<br />

Air leakage from after cooler joint also. Same attended & given fit.<br />

BWN arrived at 9:35 hrs, Departure at 10:17 hrs =42”<br />

On checking at HWH shed found TM6 slight flash mark. Impeller of<br />

MVRH 4 nos of bolt open condition.<br />

Loco checked at ELS/ASN on 24.06.11 .On checking found no supply<br />

in cable no G‐100 at cab1 SB supply checked at BD found normal.<br />

Fresh cable lay out done from BD to SB‐1 & found both CP working<br />

normal. Conclusion‐ No continuity was in cable no G‐100 from BD to<br />

SB‐1<br />

ELS/SRC:Coupler cables (3 Sq cm) cab‐2 from MP to SB‐2,one cable cut<br />

and three cable insulation damaged due to severe sulphation.<br />

ELS/VSKP: SMGR reducing valve changed(Shavo make).Old valve was<br />

having over sized.<br />

SIV Material CR<br />

CTF Warranty failue (Firm) CR<br />

TM + Crew ( Shri<br />

S.P.Bhakare)<br />

Material<br />

CR<br />

HV cable Maint/Shop CR<br />

TM Bearing Material CR<br />

SIV<br />

MPCS<br />

Aux motor Elect<br />

Misc/loco<br />

Pn pipe line<br />

Aux motor Elect<br />

Cable<br />

Material failure<br />

Firm<br />

Material failure<br />

Bad maint/WCR<br />

Mal opration by Dr.<br />

Material failure<br />

Material failure<br />

Material failure/ POH<br />

KPA.<br />

HT/LT Cables Defective Material ECoR<br />

SMGR Defective Material ECoR<br />

ER<br />

ER<br />

ER<br />

ER<br />

ER<br />

ER<br />

ER<br />

ER

3 4‐Jun‐11 210 20684 WAT ECoR Train BRAG dept at 19.35 hrs and stopped at Km no 415/10 at 19.45 hrs TLHR Staff: Wedged removed and checked found OK. Misc.(Loco Equipmets) Misc ECoR<br />

due to MR & BP dropped. So LP checked and found all the three CPs<br />

are not working. so he checked as per TSD and found CCA is ok and<br />

blowers are also working. So as per SSE/BBS's advice, LP clamped C‐101<br />

and site departed<br />

4 7‐Jun‐11 2422 22623 GZB NR After passing JJKR at 14.20 hrs train stopped at Km no 337/17 at 14.22 SE/TRS/BBS checked the loco at BBS and found MR‐3 drain plug was<br />

hrs due to pressure drop. On checking LP found drain cock of MR‐3 was broken. Same was attended and loco given fit.<br />

broken causing air leakage. So LP tried to arrest leakage using wooden<br />

block but could not success. So he asked for relief loco at 14.45 hrs.<br />

Finally with the help of relief loco no 13183/13106/BNDM train section<br />

cleared to JKPR at 15.48 hrs.<br />

5 8‐Jun‐11 78407 21307 WAT ECOR LP experienced Loco tripping through operation‐A at 6.10 hrs on<br />

checking he found smoke emission from ARNO. So he asked for relief<br />

loco at 6.15 hrs. Finally with the help of relief loco no 28310/ANGL<br />

train departed from BHC at 7.15 hrs.<br />

6 10‐Jun‐11 1 VK 23065 WAT ECoR FIR by SCR train stalled between BDVR‐SLPM at KM No.36/5 due to<br />

heavy grease on track. To avoid rail burnt LP asked relief power. 9.45<br />

hrs BT loco 26022 SUP dep. BDVR arrived LE 10.00 hrs. Dep from<br />

BDVR at 10.05 hrs. 1 VK pass site dep with banker power. LP<br />

demanded banker. Required upto SMLG to avoid further stalling.<br />

SLPM dep with banker at 10.55 hrs. (Sand intact, working) (Mechanic<br />

accompanied LR Das)<br />

Misc.(Loco Equipmets) Defective Material ECoR<br />

Arno was meggered found earthed. Arno was opened and checked<br />

found rotar arno bars were cracked and flash marks on motor.<br />

Due to arno motor bar cracks, flashes and smoke developed inside the<br />

arno.<br />

ARNO Defective Material ECoR<br />

STEAM SHED: L/23065 was checked at Steam Shed and found all TMs<br />

are working condition. Sanders function was checked and found air<br />

coming from sander nozzle but sand not ejected. Sander was opened<br />

and found the path way of sand was obstructed with stones and other<br />

foreign material. After cleaning, sanders working normal.The loco was<br />

stalled due to grease and not working of sanders due to bad quality of<br />

sand.<br />

Misc.(Loco Equipmets) Defective Material ECoR<br />

7 10‐Jun‐11 E/MJAC/GYP 27407 MGS ECR LP taken over charge of the train ordered at 3.30 hrs and waited for<br />

line clear. At about 5.45 hrs sudden heavy rain and wind with lighting<br />

started and then LP experienced no tension. Then LP tried to close DJ<br />

but again DJ tripped with no tension. Same was informed to TLC/KUR<br />

and joint checking was done with TRD staff.<br />

Findings at <br />

Joint checking was done by LI/PRDP and JE/TRD/RHMA at 13.30 hrs<br />

and found polythene on PT‐1 causes DJ tripping. Same was removed<br />

and loco was allowed to work at 14.45 hrs<br />

Misc(Operational/Crew<br />

/Others)<br />

Misc<br />

ECoR<br />

8 13‐Jun‐11 SC/CONC 23732 BIA SECR At 21.00 hrs O/G LP informed that L/L23787 between wheel No. 7 & 9<br />

bridge plates deficient. At 21.50 hrs LI sri N.Sikdar checked and<br />

informed it is unsafe to run and Loco made TR at SCMN to plan to<br />

shed. MELE departure at 00.25 hrs and at 01.40 hrs Dyd arrived.<br />

ELS/VSKP:In Loco 23787 bridge plate provided and loco made ready. Misc.(Loco Equipmets) Defective Material ECoR<br />

9 14‐Jun‐11 BVC 9/23 21122 WAT ECoR At 02.35 hrs LP informed while approaching ARK experienced tripping<br />

through QOA dropped in M/L 21122 and same checked and found<br />

R118 Smoke emission. So loco made dead and train cleared section<br />

with two locos. Same informed to PPO and SSE/KRPU. Consist made TR<br />

at ARK.<br />

10 14‐Jun‐11 804 27991 CNB NCR At 03.45 hrs LP informed that while approaching CHE home signal in<br />

curvature checked and found sparks coming from axle No.4. On @ CHE<br />

Yard checked and found axle No.4 not rotating. At 03.50 asked for<br />

relief loco and relief loco 23044/23239 (BRC) arranged and EOT in rear.<br />

At 05.27 hrs train backed to route No.1 loop line at 05.55 hrs Loco<br />

reversed to Dn direction and EOT at 06.00 hrs. At 06.10 hrs BP ready<br />

and at 06.25 hrs departure from CHE.<br />

ELS/VSKP: L/21122 was checked found R118 having overheat<br />

symptoms and 3 grids were melted and deformed. Arno found good.<br />

Circuit was checked found good. QCVAR, Q45, C118, RC118 were<br />

checked and found normal. QCVAR pick‐up found 155 V and drop<br />

out 68 V. Due to over<br />

age of R118, 2‐3 grid elements got weakend resulted to melting of grid<br />

& QOA.<br />

GR/RGR/CGR Defective Material ECoR<br />

ELS/VSKP:Tm‐4 pinion removed and wheel set no.4,5, &2 TT done and<br />

TM‐4 islated and given fit in TM working and send to home shed for<br />

attention.<br />

Traction Motors Defective Material ECoR

11 14‐Jun‐11 LE/NEYT 28100 ANGL ECoR At 15.00 hrs LP informed that while closing DJ BLVMT, SIV tripped due<br />

to external fault. Switch OFF Battery few times again DJ closed same<br />

trouble experienced. So as per TLC advise HSIV kept on '0' and cleared<br />

the section. At 16.20 hrs GPL departure and at 18.10 hrs SCMN @. On<br />

@ SCMN power made TR.<br />

12 17‐Jun‐11 TLHR/BOB 27760 NKJ WCR Train KED dep. at 9.28 hrs and stalled at Km no 311/1 at 9.35 hrs due<br />

to DJ tripping and on checking LP found Q‐30 burnt. Same was<br />

informed to TLC and asked for relief loco at 9.45 hrs. Finally with the<br />

help of the relief loco no 23676/ET train section cleared to MZZ<br />

ELS/VSKP: MVMT1 changed at ELS/VSKP. Auxiliary Motors Defective Material ECoR<br />

KUR Mant.Staff: Q30(ABB) relay changed. Relays Defective Material ECoR<br />

13 22‐Jun‐11 ME/NYG‐N BOX 27722 BNDM SER While passing STBJ at 22.55 hrs LP experienced OHE voltage raised up<br />

to 32 KV causing DJ tripping. Then he tried to close DJ but found SIV<br />

not picking up with H‐4(external fault lamp) glowing. Same is informed<br />

to TLC and after reducing of OHE voltage to 27 KV, LP tried to close DJ<br />

but found same problem. Then he tried as per TSD, kept HRAVT on "0",<br />

kept all auxiliary switches on "0" and tried to close DJ but no success.<br />

So LP made loco de‐energized for 25 mins and then tried to re‐energize<br />

the loco but no success. So as per the advice of TLC, LP cleared load up<br />

to KDJR at by kept HSIV on "0" and pressed ELD bypass and left STBJ at<br />

1.55 hrs and cleared load up to KDJR.<br />

ELS/BNDM: Loco send to BNDM with wkg loco 27798 and found no<br />

any abnormality at shed.SIV(Hirect make)<br />

SIV Defective Material ECoR<br />

14 24‐Jun‐11 N/BOOST NPL 27204 AQ CR Train NRG arr. At 11.30 hrs. at 12.15 hrs LP experienced tripping and on<br />

checking found panto in lowered condition. So LP checked CCPT and<br />

found melted. Same was replaced and LP again tried to close DJ and<br />

again CCPT was melted. So LP put HBA on OFF condition, replaced<br />

CCPT and tried to close DJ but again CCPT was melted. Finally LP<br />

reported to TLC at 12.30 hrs and asked for relief loco at 12.30 hrs.<br />

Loco checked by maintenance staff/KUR and found Q‐45 & Q‐30<br />

burnt.Loco send to AQ shed as relay was not available at ELS/TLHR.<br />

Relays Defective Material ECoR<br />

15 24‐Jun‐11 PRNA/BCN 23135 BZA SCR At 15.55 hrs GVI through passed. After passing GVI, LP reported that<br />

Cab‐2 leading both horns not working. At 16.08 hrs stopped on<br />

through at CPP, checked and informed both horns not working. All<br />

MRs completely drained and checked but trouble not rectified. At<br />

17.00 hrs again LP informed that Loco made dead and all 4 MR<br />

completely drained and MR building up and checked eventhough<br />

trouble not rectified.<br />

ELS/VSKP: Chekked and found D/valve jammed,same attended and<br />

found working nornal.<br />

Misc.(Loco Equipmets) Misc ECoR<br />

16 25‐Jun‐11 58502 23023 WAT ECoR At 16.15 hrs LP informed that train detaining at KM NO.174/13 ELS/VSKP: l/23023 was checked for smoke near RGR. 1) No relay Transformer Defective Material ECoR<br />

between SXV‐PBV due to loco trouble and LP demanded relief loco. OK targets were dropped. 2) RGR was found good and value was 2<br />

115/15 @ PBV. At 17.55 hrs MELE/15 detached and departure from<br />

PBV for section clearance. At 18.00 hrs 2VK @ PBV with relief loco. At<br />

18.05 hrs LP reported that after passing N/S between SXV‐PBV on<br />

closing DJ experienced loco tripping with heavy sound. On checking<br />

found smoke emission near RGR. No relay target dropped and DJ not<br />

MOhms. 3) ET‐1, ET‐2 gaps were 210 & 80 mm respectively. 4) VCB<br />

damping circuit was checked found 24.8, 24.9 Micro Farad (25 micro<br />

farad) 5) Capacitors near a0, a1, a2, a8 bushing were flashed<br />

condition. Its fixation bolts were flashed badly. 6) 991 cable<br />

connected to capacitor was flashed and conductors were melted. 7)<br />

closing hence demanded relief loco. At 18.05 hrs 26022 departure from 991 cable from capacitor to Q30 relay was completely damaged. 8)<br />

SXV which is nominated for 2VK working. At 18.25 hrs PBV@ and EOT Capacitor values were checked found (a) 0 Micro farad (b) 1.04<br />

with 2 VK at 18.25 hrs. At 19.10 hrs departure from PBV with dead loco micro farad (1 micro farad) 9) TFP BDV, DGA found satisfactory. (10)<br />

23023 and VSKP arrived at 02.05 hrs.<br />

At the time of incidence the OHE voltage was 25.9 KV ( 16.0.12 sec,<br />

16.0.52 sec) (11) SMGR function was checked found normal. Due to<br />

heavy surge after passing neutral section, the capacitors of Aux<br />

winding got flashed and its cable was damaged resulted to smoke and<br />

tripping of loco Capacitance values check

17 29‐Jun‐11 17481 27936 WAT ECoR At 23.40 hrs LP informed to CC/VSKP that Cab‐2 heavy air leaking from<br />

BP angle cock vent hole after EOT. C&W staffs attended but not<br />

succeed. Li PMV Diwaker attended with mechanics but not rectified.<br />

Advised to arrange relief power. At 00.15hrs L/27936(WAT) detached<br />

from train and L/21240(AJJ) given bar line and EOT done at 00.30 hrs<br />

and BP ready and departure at 00.40 hrs.<br />

STEAM SHED: Loco was checked found exhaust port leakage from<br />

cab‐2 BP angle cock. BP angle cock was changed.Defective angle cock<br />

was opened and found its valve seat (Gasket) was damaged<br />

condition. Due to damage of the valve seat, BP angle cock EP leakage<br />

was expd during open condition.On 28/06/11 external pressure<br />

checking was done. During testing (cab2) efficiency test was done<br />

from rear cab‐1.External pressure testing was done by Sri Ganga Rao,<br />

Gr.I, T.No.269.<br />

Pneumatic Valves Bad Mant.(Shed) ECoR<br />

1 05.06.11 BSCS 31283 BIA SECR Train controlled at CDMR.On starting, BP dropped. LP reported that<br />

MCB 100 tripped and CP not working. LP reset MCB 100 but CP not<br />

working. Then put electronics off & on and found normal. Gave ready<br />

at 04:50. Train left at 05:10. Train arrived in SEB loop at 08:50. LP<br />

reported MCB 100 tripped again & again and Battery charger not<br />

working. Loco failed at 09:15.<br />

2 05.06.11 12301 30282 GZB NR Train passed CDMR at 00:33. Loco tripped at 00:39 and not resumed.<br />

Message displayed‐SS01 0109 P1 Main power assistant winding over<br />

current. As per DDS BUR max.current 039/012. Train arrived GAQ at<br />

00:45 in coasting. LP put electronics off & on and found loco normal.<br />

ELS/GMO checked ‐ MCB 100 tripped & BA charger not working. BUR2<br />

BUR3 ‐ WRE module interchanged then loco became OK.<br />

Train left at 00:51. At MGS LI V.B.Pathak checked and found<br />

normal.Loco made over to NCR working the same train.<br />

3 Ph FR Case ECR<br />

3 Ph FR Case ECR<br />

3 05.06.11 GHTL 28062 SIV‐<br />

Hirect MPCS‐<br />

Steslite<br />

ASN ER Train stopped bet RFJ‐DEO RD due to loco tripped and message givenfault<br />

in diagonestic control system. LP tried but loco not<br />

closed.L/31254 arrived site & onload in front at 05:00, pressure ready<br />

at 05:15 and train left at 05:20. .<br />

4 09.06.11 53612 22804 MGS ECR Trainarrived KCKI and SIV autometically off & LSCHBA glowing. Internal<br />

fault lamp glowing also. LP tried to rectifie but not success. So, loco<br />

failed.<br />

5 15.06.11 03127/spl 27522<br />

STC‐AAL<br />

6 17.06.11 PNP 27505<br />

SIV‐Siemens<br />

MGS ECR Train stopped between PKA‐DHN due to DJ tripped via QSIT and QSIT<br />

became permanent. LP put HBA OFF & ON & isolated block‐1 then left<br />

site at 19:09. Train arrived DHN at 20:00 with same trouble occurred<br />

again & again. Another loco 24017 O/L in front of dead loco‐27522 at<br />

20:20, P/R at 20:30, left DHN at 20:54.<br />

CNB NCR Train arrived GAYA without pre‐information about defects that BA<br />

charger not working.LP reported that DJ tripped & QSIT dropped and<br />

external fault lamp glowing. So loco made dead by LP and wait for<br />

some times then tried to energise but not success. Another loco 27242<br />

O/L train left 8:10 with dead loco 27505.<br />

ELS/MGS checked ‐ Battery no. 8 showing reverse polarity. Same<br />

battery changed then OK.<br />

ELS/GMO checked‐ SIV blower over heated and not working as its<br />

delevary hole chocked. Firm (Simens) staff attended and given fit.<br />

ELS/MGS checked ‐ MVSL1 bonded & open circuited. MVSL1 changed.<br />

(Make‐HBB, R/W on 10.08.06 at KPA, DO O/H‐ 26.11.09, DOF‐<br />

04.01.10)<br />

ELS / MGS checked in put insulator terminal flashed and cut & other<br />

same wire also cut Loco directed to base shed due to firm staff has<br />

not agree to attended at MGS asout of warranty Make siemence.<br />

Battery FR Case ECR<br />

SIV Material Failure ECR<br />

Aux. Mach Elect Material Failure ECR<br />

SIV FR Case ECR<br />

7 18.06.11 12024 22311 HWH ER Train arrived JAJ LP reported that flashing from BA charger but BA<br />

voltage showing 100 V.Loco checked by LI & M/Staff TFP cable which<br />

come in BA charger flashed and cable open out and CHBA not<br />

working.Another loco 24408/BL O/L in front of dead loco P/R left<br />

15:20<br />

8 18.06.11 NE 27993 SIV ‐<br />

HIRECT<br />

9 19.06.11 PKW (Sangam) 28284 SIV‐<br />

Hirect)<br />

CNB NCR Train stopped between JPL‐HDN due to DJ tripped via QSIT . LP made<br />

loco dead & put HBA OFF & ON then DJ closed and left site but again<br />

stopped between KVQ‐MDJ due to QSIT dropped & DJ tripped ,<br />

message given rectifier over temp and internal fault lamp glowing.Asstt<br />

loco 27034 arrived & O/L in rear of MT & left site by pushing at 0:15,<br />

arrived MDJ at 0:45. Then 27034 detached from rear & O/L in front of<br />

dead loco left 1:45.<br />

MGS ECR Train stopped in main line PRY at 14:08 due to loco tripped on<br />

coasting. On checking found QOP‐2 & QE dropped with smoke from<br />

SIV. Loco failed at 14:30. Multi loco 28284 + 24019 onload at 18:30,<br />

pressure ready at 18:45 and train left PRY at 19:10.<br />

Loco Jointly checked at ASN shed by CLI/UDL & JE/ASN<br />

BA charger 2 nos tap lead of charger tranformer was cut from<br />

lug.same attended.<br />

AS per CT LC/MGS loco will go to bash shed as dead SIV deft. Make<br />

HIRECT<br />

CHBA FR Case ECR<br />

SIV FR Case ECR<br />

ELS/MGS checked cotactor C‐145 Arc‐ chute burnt and C‐145 flashed.C‐ Contactor Material Failure ECR<br />

145 & its Arc‐chute changed. Make‐ CLW commissioning 04.02.11

10 20.06.11 BVH 23413 TKD WCR Train arrived in UP Central yard MGS at 23:50 without any preinformation<br />

of defect.LP reported at 00:05 that both side speedometer Make AAL<br />

ELS/MGS checked found power supply card burnt .Same changed<br />

not working. PPO staff arrived at 01:00 and reported SPM master card<br />

defective & demanded loco in shed. Loco detached at 03:00 and<br />

placed in ELS MGS at 04:00.<br />

11 23.06.11 LHM 27502 GMO ECR Train stopped NMG‐PNME due to loco tripped. On checked ammeter<br />

not deviating & all TM not responding. LP manualy operted push<br />

button for line contactors found loco ok.Train left at 22.25 hrs.section<br />

cleared.<br />

12 29.06.11 NE 31205 BIA SECR Train arrived in GAQ 2nd loop at 09:40 for L/C. LP reported at 10:05<br />

that message given‐aux convertor 2 & 3 isolate & Bogie‐2 isolate. LP<br />

put electronics off & on but not success. (LP talked with LI B.Das. LI<br />

B.Das reported‐ Both panto not raising & Main power off). Loco failed<br />

at 10:35. LE 28165 onload at 13:00 to clear the load.<br />

PPO Staff changed the AM‐4 on 23.06.11. Line contactor operated by<br />

push button switch then normal<br />

ELS/GMO checked ‐ Earth fault in Auxiliary Circuit. Loco is under<br />

testing.<br />

SPM FR Case ECR<br />

Line contactor Transient ECR<br />

3 Ph FR Case ECR<br />

1 02.06.11 12226 22732 GZB NR DJ tripped with external fault in SIV. At GZB shed found MVSL‐2 IR value 0 Mega Ohms. MVSL‐2 changed. Auxiliary Motors Mat NR<br />

2 17.06.11 BXB 28042 GMO ECR Relay QOP‐2 permanent dropped. Loco checked at UMB, found SH‐AA5 (shunting for Ammeter of TM‐5)<br />

busbar connecting strip burn out. Loco sent to home shed as dead.<br />

Traction Motors Mat NR<br />

3 25.06.11 12057 22050 GZB NR Heavy air leakage from GR drum & notches not coming. SMGR; VE‐1 and G4/5 valves incoming pipe a foreign material came in, GR Misc NR<br />

which causes plunger assembly stuck in open position and air laekage<br />

permanently. Same claened and loco became normal.<br />

4 26.06.11 12014 30019 GZB NR Disturbance in converter no‐2. Loco checked at GZB and found DDS: ASC2 PS fault storage CGP and Traction Converter Mat NR<br />

GBC, hence SR‐2, 12/3; V1 & 13/2; V2 GTO found short circuited,<br />

hence valve sets changed.<br />

5 26.06.11 14553 22652 GZB NR Smoke emission from loco with blast, DJ tripped. Loco checked at GZB shed and found incoming wire from bushing a0‐ HT/LT cables Mat NR<br />

a1 to SIVs SB (wire no. 991) thimble broken and flashed, hence cable<br />

changed.<br />

6 29.06.11 11078 22688 LDH NR Abnormal sound from GR assembly while progressive & regressing Loco checked at NDLS and found RGR smoke, GR internal gear RGR Mat NR<br />

notches.<br />

alignment disturbs. GR was stuck up in between notches but GR<br />

interlock did not sent message to MPCS to open DJ through Q‐44 by<br />

de‐energizing Q‐44.<br />

1 1‐Jun‐11 12387 21391 MGS ECR ICDJ. On checking found CCDJ, CCBA were OK. Q 118, Q 45 OK. C‐118<br />

working was OK. Tried from Q 45 and BP‐2 DJ and Q 44 but not<br />

succeeded. Tried from rear cab but not succeeded. Put HQOp‐1 and 2<br />

on OFF and HQOA on zero but not succeeded. Fresh loco given. Loco<br />

was checked at ANVT and found normal.<br />

2 1‐Jun‐11 14866 30033 GZB NR All pilot lamps were not glowing. Loco shut down and then energised from rear cab. But not succeeded.<br />

Fresh loco given. Loco was checked at ELS/GZB and it was found that<br />

DC DC converter for 24 v was defective. It was changed and loco given<br />

fit.<br />

3 2‐Jun‐11 13239 22544 CNB NCR Observed smoke from underframe below iron plate in cab‐1 MP side at<br />

a speed of 80 kmph.<br />

On putting MP on 0, there was no smoke from cable. DJ did not trip<br />

and no relay dropped. The smoke was from a hole near MP. Loco was<br />

escorted by LI. As per ELS no QOP, QOA relays or any other ones<br />

dropped & fuses were OK. No DJ tripping occurred during testing in<br />

shed. On removing MP from foundation it was found all cables &<br />

wires were healthy. It is obvious that burning agarbatti & matchsticks<br />

fell inside MP‐1 causing smoke of rubber. Sticker for Agarbatti lighting<br />

has been pasted in the cabs.<br />

Control Circuit Misc NCR<br />

ABB Material NCR<br />

Misc Crew NCR<br />

4 2‐Jun‐11 BAD Spl 23821 GZB NR ICDJ. Loco fitted with SIV AAL make. Single phase fault appeared. Smoke and bad smell was noticed in HT<br />

compartment. Fresh loco given. As per investigation, smoke signs<br />

were seen from inside the card panel. SIV was not functioning and<br />

there was internal fault in it.<br />

Static Inverter Material NCR

5 3‐Jun‐11 12189 30232 GZB NR Catenary voltage showing out of range and message F 0104 P‐1<br />

appeared on screen.<br />

Meter in loco and TPC both were showing 25 kV. Tried from rear cab<br />

and isolated both bogies one by one. Closed VCB in cooling mode but<br />

not succeeded. Fresh loco given. Checked at NZM/TS VCB was not<br />

closing after MCE was put off and when both bogies were OFF one by<br />

one.It was attended by GZB staff and SR‐1 & 2 200/4 volt OHE sensing<br />

transformer was changed on 2.5.11 at ASN and given fit. As per<br />

ELS/GZB, its DJ coupler was found defective. It was changed and given<br />

fit.<br />

ABB Material NCR<br />

6 3‐Jun‐11 12440 22534 GZB NR 6th notch tripping occurred. Troubleshooting done and wedged Q 118 relay and succeeded. Again<br />

after passing CHL neutral section QOP‐2 dropped permanently. At TDL<br />

C‐107 auxiliary interlock operated 2‐3 times and got success. But QOP‐<br />

2 dropped again permanently. Fresh loco given. TM meggered at both<br />

ends of reversers and IR values found OK. There was excess grease in<br />

TM‐5 CE bearing side. TM‐5 was OK. As per ELS/GZB, all TMs were OK.<br />

Loco was lifted and bogies interchanged. As per CNB QVMT‐1 relay<br />

was showing some problem which was changed and QVRH relay<br />

adjusted.<br />

Relay Maintenance NCR<br />

7 4‐Jun‐11 LE 27684 LDH NR Unusual sound coming from wheel no‐9 and 10. Unusual sound could not be traced even checking all TMs. Finally loco<br />

was sent to JHS shed where it was found that its pinion teeth was<br />

broken. It was removed and given on 5 TMs.<br />

8 5‐Jun‐11 12723 30273 LGD SCR Throttle was not responding after ACP even putting switch no 154 on<br />

1st.<br />

9 5‐Jun‐11 51811 21320 AJJ SR Fitted with SIV of AAL. SIV starting and stopping on its own.<br />

Sometimes DJ opened also.<br />

Put MCE OFF & ON. But not succeeded. Put MCB 110 OFF and reset<br />

MCB 112.1 and then CE was put ON. Same loco worked. It was due to<br />

fault of LP who failed to put MCE OFF & ON. Same loco worked. As<br />

per ELS/LGD, loco was found normal and was given fit. This was<br />

reported as per SCR L.N. 223/Optg/Loco/XIX/1451 dtd 17.6.11.<br />

Put BA Off and ON. Loco became normal for a few moments. Again<br />

after BJI SIV was not working. Fresh loco given. Loco was checked at<br />

JHS and PCB for SIV was not available. Loco was sent dead to home<br />

shed.<br />

10 6‐Jun‐11 Up AK Spl 31200 TKD WCR Load stalled at km 1098/15 after passing BAB since braking applied on<br />

observing cattles on track.<br />

After stopping loco was not able to haul the load. Fresh loco given for<br />

working.<br />

11 8‐Jun‐11 MUT MLY 27889 WAT ECoR SIV not working. DJ was not holding. Message on screen for ON COMMAND appeared. No fault lamp was<br />

glowing. Fresh loco given. As per ELS/JHS, there was air leakage from<br />

magnet valve of DJ. Same was attended and rectified and given fit.<br />

TM Material NCR<br />

ABB Crew NCR<br />

Static Inverter Material NCR<br />

ABB Stalling NCR<br />

DJ Material NCR<br />

12 8‐Jun‐11 E Box Up 27079 MGS ECR Split pins for brake rigging on wheel no 3,4,5 & 6 were deficient. TM‐2<br />

horizontal nose pad pin was also deficient.<br />

13 9‐Jun‐11 Dn PTNR 27432 KZJ SCR After passing BIN AGD neutral section, DJ not closed. After some time<br />

DJ closed automatically.<br />

Same was secured by wire and given fit. Brake Rigging Maintenance NCR<br />

At KAO DJ was not holding. Advised to put HPH, HVSL‐1 & 2 on 3rd.<br />

HQCVAR on 0 but not succeeded. Not succeeded from rear cab. Fresh<br />

loco given. Loco was checked at JHS shed and found pressure for VCB<br />

(Single bottle type) was less 4.4 kg/sq cm. Same was re‐adjusted to 5.2<br />

kg/sq cm. QPDJ relay was defective. Same was changed.<br />

Relay Material NCR<br />

14 10‐Jun‐11 WL Up 31061 AQ CR Cab‐2 LP side railguard bent inside completely. Loco was sent to ELS/JHS. Fresh loco given. CAB‐2 LP side rail guard<br />

changed and given ready.<br />

15 12‐Jun‐11 12308 22772 HWH ER SIV (HIRECT) not starting. On closing DJ, LSCHBA was not extinguishing. Put HBA Off and ON and again tried but not succeeded. Fresh loco<br />

given. MPCS No. 20018 F/10809/183 mfg yr 2008 make HIRECT. SIV<br />

S.N. 2006L‐10166/08 mfg Dec 2006.<br />

16 14‐Jun‐11 12418 30014 GZB NR Disturbance in converter no‐2 appeared. Message F 0301 P‐1. Bogie no‐<br />

2 isolated itself.<br />

17 14‐Jun‐11 PNP Dn 31212 TKD WCR Auxiliary converter no‐2 isolated with message F 0702 P‐1 & F 0306 P‐1<br />

appeared.<br />

After some time message of isolation of angle transmission appeared.<br />

F 1803 P‐1. Put MCE OFF & ON. Nad switch 152 on 1st and got<br />

success. But bogie no‐2 isolated itself. As per DDS life sign from SLG‐2<br />

was missing. Same loco worked. As per ELS/GZB, optical fiber was<br />

changed.<br />

Put MCE OFF & ON and then fault message for isolation of Auxiliary<br />

converter nos 2 and 3 also appeared. Fresh loco given.<br />

Railguard Material NCR<br />

Static Inverter Material NCR<br />

ABB Material NCR<br />

ABB Material NCR

18 16‐Jun‐11 14853 30241 GZB NR Both compressors were not working when loco was worked from cab‐<br />

1.<br />

19 17‐Jun‐11 Up JNPT 31218 TKD WCR Fault message F 1005 P‐1 appeared. Traction with auto brake fault<br />

appeared.<br />

20 17‐Jun‐11 12301 30281 GZB NR Bogie no‐1 isolated itself with fault message F 0201 P‐1 appeared on<br />

DDS. Disturbance in converter no‐1.<br />

21 19‐Jun‐11 Dn HRI 28149 LDH NR SIV (AAL) and MPCS (MEDHA) fitted loco. Notches not progressing after<br />

1st notch. And was reversed back automatically on its own. On DDS<br />

message of GR not progressing through Q‐52 relay.<br />

Put MCE OFF & ON but not succeeded. Fresh loco given. As per joint,<br />

compressors were not working from cab‐1. All switch connection of<br />

BLCP was normal. On shorting the switch both CPs started working.<br />

From cab‐2 also CPs were working. As per ELS/GZB, cab‐1 panel was<br />

changed and loco given ready.<br />

Auto brake was already released. Again message of fault in brake<br />

electronics appeared. F 1001 P‐1. Put MCE OFF & ON and worked.<br />

Put MCE OFF & ON but not succeeded. Speed was picking upto 130<br />

kmph. After CHK throttle was not responding. Loco was sent dead to<br />

home shed.<br />

Put HPAR switch on bypass mode but not succeeded. Fresh loco<br />

given.<br />

ABB Material NCR<br />

ABB Material NCR<br />

ABB Material NCR<br />

Static Inverter Material NCR<br />

22 20‐Jun‐11 12875 22721 GZB NR ICDJ. Put HBA on 0 but not succeeded. As per troubleshooting Q 44 relay<br />

was getting de‐energised. Advised to move GR from 0 to 10 and then<br />

back but not succeeded. Tapped Q 30 relay but now QOP‐2 dropped<br />

permanently. Fresh loco given. As per report of GZB, loco was found<br />

normal.<br />

Control Circuit Misc NCR<br />

23 21‐Jun‐11 12877 22622 GZB NR MVSL‐2 not working. Fresh loco given. As per PPO/GZB, MVSL‐2 connecting cable wire was LT Cable Material NCR<br />

cut. Same was changed and given fit.<br />

24 22‐Jun‐11 HPU Dn 27770 AQ CR SIV AAL. Internal fault lamp was glowing. Put HBA on 0 for 3 minutes but not succeeded. Now put HRAVT on 0 Static Inverter Material NCR<br />

but still internal fault lamp was glowing. Fresh loco given.<br />

25 23‐Jun‐11 HSRA Up 31154 LGD SCR Bogie no‐2 was isolated. It was received ex PWL on half traction. Loco failed and fresh loco given. ABB Material NCR<br />

26 23‐Jun‐11 12945 22751 MGS ECR TFP oil not visible in gauge glass. No preintimation was given by TLC/TDL. This loco was received while TFP Maintenance NCR<br />

working in T.N. 12946. Fresh loco given.<br />

27 24‐Jun‐11 SOG Dn 23085 TKD WCR MU with 23566. CCDJ fuse melted in leading loco 23085 as CCDJ fuse Same changed and worked. Fuse Material NCR<br />

melted.<br />

28 24‐Jun‐11 TAPG Dn 27351 TKD WCR One end of cotter pin on wheel no‐11 equalising beam found broken. Same pin was taken out and refitted after proper machining and Bogie Item Material NCR<br />

grinding.<br />

29 25‐Jun‐11 18507 22030 GZB NR TM‐5 running warm. Loco was checked at ELS/JHS and it was found that suspension bearing Suspension Bearing Maintenance NCR<br />

oil level was below minimum mark. This caused SB metal out in TM‐5.<br />

Its TI was done at ASR on 22.6.11. Bad maintenance by TI shed.<br />

30 26‐Jun‐11 DDL Dn 27037 MGS ECR One end of the cotter pin on wheel no‐9 beam was broken. Cotter pin was provided and loco given ready. Bogie Item Material NCR<br />

31 26‐Jun‐11 14011 28321 BIA SECR ICDJ. MPCS (STESALIT) & SIV (SIEMENS) fitted loco. No fault lamp was glowing and message on BLDJ. Put HBA on 0 and<br />

HOBA on OFF. Checked all fuses and switches but not succeeded.<br />

Fresh loco given. As per DDS display unit of SIV unabled.<br />

Static Inverter Material NCR<br />

32 27‐Jun‐11 11078 22615 LDH NR Unusual sound coming from bogie no‐1 at a speed of 15 kmph. Fresh loco given at JHS station. Checked at ELS/JHS and no<br />

abnormality was found after dismantling gearcase no‐2. One staff was<br />

deputed for escort of the loco and no abnormality was found during<br />

run. Loco was sent to home shed.<br />

Gearcase Material NCR<br />

33 28‐Jun‐11 MXX Dn 31094 AQ CR MCB no 53.1/1 for traction motor blower tripped. Message F 1101 P‐2 Put MCE OFF & ON but same MCB tripped again. Loco worked on half ABB Material NCR<br />

appeared.<br />

traction.<br />

34 29‐Jun‐11 SOG Dn 27370 NKJ WCR Oil leakage from delivery pipe near MPH. On checking found there was a bent of 90 degrees and there was a<br />

slight crack at the bent point causing leakage. The threads of joint<br />

plug of MPH and copper pipe were slack causing leakage. It was<br />

leaking @ 120 drops per minute. Fresh loco given.<br />

Pipeline Material NCR<br />

35 30‐Jun‐11 13007 22863 HWH ER At HDL, LP reported that copper pipe in cab‐2 located below wiper cut<br />

out cock was leaking heavily.<br />

Tried to troubleshoot but could not. Fresh loco given. As per<br />

investigation, copper pipe material was weak which burst on its own.<br />

Pipeline Material NCR

36 30‐Jun‐11 12421 22622 GZB NR Observed smoke emission from marker light no‐1 under ALP side at km Used fire extinguisher but not succeeded. As per joint checking there<br />

1072/01.<br />

was short circuiting inside the switch board. Fresh loco given. As per<br />

joint cab‐1 inside sub board no‐4 wire nos 966, 968 & 984 were<br />

disconnected from thimble and other wires of microprocessor were<br />

also burnt. Sub board no‐4 of MPCS smoked.<br />

LT Cable Maintenance NCR<br />

37 30‐Jun‐11 12002 30024 GZB NR On approach of DBA, distrubance in converter no‐1 appeared. DJ On checking it was found panto was not rising. Put MCE OFF & ON and ABB Material NCR<br />

opened and panto came down. Message F 0201 P‐1 appeared. raised front panto.<br />

38 30‐Jun‐11 E Box Up 24516 JHS NCR GR oil was below 20 degrees, and oil was leaking from GR. Fresh loco given. As per JHS GR oil was below ‐20 deg and oil was Tap Changer Maintenance NCR<br />

leaking from GR. GR body was cracked from top side.<br />

1 2‐Jun‐11 16328(TVC‐KRBA) 22536 ED SR Train arrived PLL(Parali) at 14.03”, LP stopped due to TLTE with out GR Loco checked at ED and found crimping of wire no 40 coming from<br />

progression and all pilot lamps not glowing after passing MNY‐PLL CCLS to BL2 through SB2, given up at conk. Hence no supply to QRS,<br />

neutral section. Started from PLL with manual control of GR, arrived and so Q51 was in energized condition.<br />

PGT at 14.22 or +17” late. At 14.25 LP informed loco working normal<br />

from rear cab so asked for relief. 27903/ED available at PGT/Yd<br />

attached at 14.45 and left at 15.03 or +53” late.<br />

control Ckt POH‐LW/PER SR<br />

2 15‐Jun‐11 16041 22808 RPM SR While working 16041 (MAS‐ALLP) Exp with Loco No 22808 RPM, LP Loco checked at ED and found J2 1 2, 8 and 12 th bits flashed. TM4 and TM Shed‐AJJ (AOH‐AJJ) SR<br />

experienced DJ tripping with QLM, QRSI 2, QOP 2 acted. LP isolated 6 Arc horn flashed, E26 and HO 2 cables flashed with body. In AC<br />

TM4 and worked up to ED.RE given at Erode. Train left after reception damping panel, one capacitor lug flashed and melted.<br />

and dispatch of 12671, reception of 16732 and precedence of 12601,<br />

with detention of 74” at ED. Detn: + 55” Summary AC Loco Direct ‐ 1<br />

3 19‐Jun‐11 12673 (MAS‐CBE) 22627 ED SR After passing KEY at 01.42 hrs LP informed MR pressure gradually Loco checked at ED and found pipe line to wiper found cut due to Pneumatic Shed‐ED SR<br />

dropped since heavy air leakage from rear cab (cab‐1) LP side wiper vibration. Clamping arrangement is being provided to avoid fatigue<br />

broken at l Union joint broken (before coc), unable to arrest and asked due to vibrations<br />

for R/E. R/E 27613/KZJ, attached on top at 02.25 hrs, train ready and<br />

left at 02.35 hrs or 57” extra. Summary AC Loco Direct‐1 12673 (MAS‐<br />

CBE)<br />

+ 44” Indirect ‐1 12681(MAS‐CBE) +25"<br />

4 19‐Jun‐11 CBU/N 42+1=<br />

3852T<br />

31136 LGD SCR Train passed thro TMV @ 15.22hrs, stopped at MTL ( Mailam) home Loco checked at VM and found DJ tripping every time with different Three phase loco Shed ‐ LGD SR<br />

signal at 15.35hrs. At 16.00hrs LP informed that due to converter 2 fault messages. Suspected control electronics card defective. Loco<br />

contactor not closing train stopped. Isolated converter‐2, but directed to HQ in dead condition<br />

experienced DJ tripping, with a message 'Lowpressure" though<br />

pressure was 9 kg/cm 2. As unable to overcome the trouble, LP asked<br />

R/E at 16.10hrs. R/E 23918/23916/ BZA I/C steel city arrived MTL at<br />

15.55hrs left 16.36hrs since no pointsman availableat station. TE<br />

attached on top at 16.45 hrs ready at 17.00hrs and train pass through<br />

MTL at 17.10hrs .Rep: 16352 ( NCJ‐CSTM) RU‐50"16351( CSTM‐NCJ)‐<br />

42" 12605( MS‐TPJ) 25" , 16128( GUV‐MS) 30", 16713 ( MS‐ RMM) 23"<br />

Gr 1in 200R<br />

5 24‐Jun‐11 06040 (TEN‐MAS<br />

spl)<br />

28272 BZA SCR Train passed OV at 08.37 hrs, LP experienced DJ tripping with LSSIT Loco checked at ELS/RPM, and found normal. Data downloaded and SIV (AAL) Firm‐AAL SR<br />

lamp glowing. SIV (AAL) display showing external fault. Trouble shoot message showing output over current & Output low voltage. Firm<br />

as per TSD , not succeeded. ELD bypassed at 08.52 , train started at staff also jointly checked and found all parameters are in order. Loco<br />

08.55 and cleared to CGL at 09.06 hrs. TBM arrived at 09.44 hrs. R/E given for service and working normal after a trial service. Suspected<br />

22009/AJJ attached at 09.48 , ready at 09.52 and left at 09.55 hrs. some transient fault.<br />

6 25‐Jun‐11 12695 22390 ED SR While working T. No 12695 (MAS‐TVC), with loco 22390 ED, train Loco checked at ED and found pin insulator shaft broken and hence DJ Material SR<br />

stopped at TCR. LP informed that DJ was opened to cut off blower and secondary contact not closing. The shaft has 50% old flaw mark<br />

while closing back, experienced LSDJ extinguishing, but DJ not closing.<br />

Suspected Secondary contact was not closing. Hence RE arranged.<br />

Summary AC Loco Direct ‐1, Detn: 12695 +89”

7 27‐Jun‐11 KCC/N LD:<br />

42/2390 T<br />

28086 ANGL ECoR After passing DSPT (Danishpet) @ 19.20 hrs, LP reported DJ tripped Stesalit make RSI, 6 tell tale fuses melted and D9 diode punctured. RSI Firm‐Stesalit SR<br />

through QLM & QRSI‐1 acted. Found RSI‐1 block 6 tell/tale fuses<br />

melted, isolated RSI‐1, energized loco and asked R/E since gradient 1 in<br />

100 R.<br />

1 03/06/11 12737 22744 LGD SCR Smoke from Gear case‐4. Relief engine given. At ELS/LGD, checked and found TM4 pinion end bearing seized and<br />

deflector came out,. Bearing make NSK/Japan, DOC;16.07.05<br />

Traction Motor Material/Unavoidable. SCR<br />

2 6/4/2011 12625 22654 ED SR VCB tripped as SIV not picking up and internal fault lamp glowing.<br />

Relief engine given.<br />

At ELS/ED, found SIV W‐phase GDU card defective. Same replaced. SIV<br />

make AAL kit‐3.<br />

SIV<br />

Material/Unavoidable<br />

Advised to SR for<br />

necessary remedial<br />

action<br />

SCR<br />

3 14/06/11 12861 23638 ET WCR DJ tripped due to heavy air leakage from SMGR filter union pipe.<br />

Worked up to CLE (chintalapalli) with manual operation of GR. At CLE<br />

Relief engine given.<br />

At ELS/KZJ, checked and found SMGR ceramic air filter incoming pipe<br />

line nipple collar worn out and came out from union caused air<br />

leakage due to improper securing of ZSMGR pannel. Pipe line<br />

replaced.<br />

Pneumatic pipe line<br />

Defective Maintenance<br />

/ Avoidable.<br />

Advised to WCR for<br />

necessary remedial<br />

action<br />

SCR<br />

1 6/18/2011 N/ ASN<br />

27974/ 27958 /<br />

WAG7<br />

BNDM<br />

SER<br />

2 6/17/2011 BOBR/BTPC 27742+27301 KZJ SCR<br />

3 6/24/2011 12801 (PUI‐<br />

NDLS Exp)<br />

20626 / WAM4 TATA SER<br />

L/Loco 27974 tripped on 18th notch. On checking found while closing<br />

BLVMT, STC not pick up & DJ tripped,<br />

T/ loco 27301 tripped with jerk. Checked & found QRSI -<br />

1+2 and QOP 1+2 dropped. On further checking found J-2<br />

not in proper direction. So J/(1+2) manually operated few<br />

times & reset the relays first time. Tested individually from<br />

T/loco 27301, having the same problem. So loco marked<br />

TR. Ld: 60/148½=5235T<br />

Tripped with detonating sound & S/E from HT compt. CLI/ADTP<br />

attended, found ICDJ, GR was operated manually few times & found DJ<br />

closed. Started from spot at 7:07hr again experienced DJ tripped with<br />

detonating sound & S/E from CGR‐1. Ld: 8/16=360TDriver‐<br />

K.Raju/ CKP<br />

SIV was tripping with glowing of external fault LED and display of<br />

SER<br />

'Earth fault' as MVRH winding burnt & earth, IR value of all phases '0'<br />

AUX/E<br />

mega ohm. Sr. no.‐ M0712789, Make‐ BBL, Type‐ MZ20M438, Mfg. yr.‐<br />

MFG/TRADE<br />

12/2007, DOC‐ 23.05.08<br />

Checked at ELS/TATA found Loco-27742 SL-1 earth, and SL MATERIAL SER<br />

in Loco-27301 TM-1&2 isolated as their IP armature<br />

became earth. Loco has been directed to ELS/KZJ for<br />

further attention.<br />

ELS/TATA ‐ Checked and found tracking took place CGR top insulating<br />

plate fixation bolt with connecting short link of CGR‐3 to RGR. CGR 1,2<br />

and 3 checked and found normal.Smoke noticed on GR horizontal<br />

shaft and vertical shaft beval gear. GR contact No.10 and 12 end<br />

portion flashed. GR vertical insulator IR value '0' .<br />

Details of GR‐ Srl.No.‐IB 304864430, Make : ABB ‐ RH done by<br />

M/s.BTI in Dec‐2010. Commissioned in L/20626 during IOH<br />

Dt.21.03.11.<br />

GR/SMGR<br />

MFG/TRADE<br />

SER<br />

18617 (HWH‐<br />

4 6/24/2011 RNC Intercity<br />

Exp)<br />

20651 / WAM4 TATA SER<br />

5 6/26/2011 Tiger BCN/E 24044 / WAG5 JHS NCR<br />

Tripping through QOP‐2 & S/E from under gear. Suspected S/E from<br />

TM‐6. So HQOP‐2 & Block‐2 kept isolated & started the train. Again<br />

same trouble between ULB – BSBP & S/E from U/Gear. Used F/Ex’R. On<br />

arrival at KGP loco detached. Ld: 12/24=600T Driver‐P.K.Shetty<br />

/ TATA<br />

After passing N/S bet DTV‐JSG exp, DJ closed but after 2‐3min suddenly<br />

tripped with QLM alone dropped & TFP oil splashed.<br />

Checked at ELS/TATA & found TM‐6 armature badly burnt, Mica came<br />

out. After dismantling found armature power coil fully stripped<br />

condition. Initially armature coil bonded. Further coil burnt due to<br />

HQOP‐2 off.<br />

Details of TM : Stator No. 092‐3419, LR/TATA 30.09.10, Arm. No.<br />

5753, FRW/TATA ‐ 15.09.10, LOD‐01.11.10.<br />

QLM dropped & TFP oil splashed. Directed to ELS/JHS for further<br />

attention.<br />

JE/SDL checked at SDL & found three nos. power cable of TFP is<br />

1 6/3/2011 18508 22034 GZB NR<br />

LP informed that loco tripped between MDXR‐GGT, checked &<br />

burnt & its insulation also burnt. (TFP cable between TFP to RSI<br />

found in HT compartment heavy smoke & burning smell, used<br />

burst) As per LP, loco tripped with QOP‐2 dropping and smoke<br />

F/extinguisher and checked found power cable near TFP is burnt<br />

& flame in TFP compartment. hence loco marked TR & directed<br />

condition.<br />

to home shed.<br />

LP reported that in loco no. 27165 ICDJ. LI/RIG Shri S. Parida<br />

2 6/3/2011 N/KDLP 27232/27165 BNDM SER<br />

attended at RIG and found DJ closing slightly, UA deviating and<br />

Suspected DJ closing contact inside VCB chamber not<br />

ARNO attempting to start then DJ trips.HQCVAR kept on 'O' but<br />

maintaining. so loco marked TR. BNDM shed report : VCB<br />

trouble could not be rectified. VCB pressure found 5.7 Kg/cm2<br />

interupter burst, (Areva make) VCB changed.<br />

was reduced to 5.5 Kg/cm2 but eventhough trouble could not<br />

be rectified.<br />

TM<br />

TFP<br />

HT\LT cables<br />

Vacuum Circuit<br />

Breaker (VCB)<br />

MATERIAL<br />

MATERIAL<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

SER<br />

SER<br />

SECR<br />

SECR

3 6/4/2011 N/KTT 23805/23769 AJJ SR<br />

As per LP whenever current increase more that 400 amps in<br />

Leading loco 23769 QRSI‐1 dropped. Current showing in cab‐2 Later QRSI‐1 dropped repeatedly. Informed to TLC and higher<br />

of same loco and both cab of rear loco is 1100 amps. Current officials allowed loco with banker to NKJ. DUE IA 25/05/11.<br />

Rectifier<br />

diffence by 700 Amps.<br />

LP informed that while performing quick inspection at O/S of<br />

CHD found in loco‐23086 PT‐2 anti balancing tube broken . Try BIA shed report: On checking found steady tube deficient<br />

4 6/6/2011 N/BOX 23086/23682 BIA<br />

to lower panto but unable to success . After clearing L/No‐2 suspected centre articulating end pin fallen causing steady tube<br />

SECR<br />

allowed cautiously in same condition but before clearing F/mark hanging and touching with panto foundation thus PT‐2 not<br />

Pantograph<br />

train stopped due to entaglement of OHE & panto broken. dropping. PT make‐AM 12 Stone India.<br />

Same secured by OHE staff. Loco directed to home shed.<br />

5 6/7/2011 Boost/FDB 27292 NKJ WCR<br />

Checked & found LED glowing for internal fault & Message<br />

LP Informed at 18.15 hrs that while entering in to BRS M/L SIV<br />

appeared on DDS , Input voltage out of range showing 575 to<br />

tripped hence train stopped in front of station building without<br />

560 V instead of 560 V.hence loco marked TR. NKJ shed report:<br />

clearing fouling mark.<br />

on checking found no trouble.<br />

SIV<br />

LP inform that while passing CHDX loco trips on checking found Inform to TLC. as per advise HOBA kept OFF & DJ close &<br />

6 6/8/2011 L/H/N/BOX 27643 ED SR CCDJ melted , so removed CCDJ & DJ close, found flashing near proceed up to BSP & at BSP m/staff checked & found Q‐45 Relay<br />

Q‐45 & also smoke emmission.<br />

base & cable no. 993 burnt, so loco marked TR.<br />

7 6/9/2011 LE 27235 BNDM SER<br />

LI‐ H N Nayak at KDTR checking found on roof two Nos. flexible<br />

LP inform that while taken over charge of LE at KDTR on L/ no ‐<br />

shunt in hanging condition & touching with loco body and nut<br />

3, On checking loco as soon as loco tripped heavy flashing<br />

of both flexible shunt uncoupled, so it was in hanging<br />

occours from PT‐2 BSP end & OHE wire broken immediately, so<br />

condition. HPT‐2 isolated & also VEPT‐2 isolated and loco<br />

Panto lowered.<br />

ready.<br />

Roof Equipment<br />

On checking found SIV external fault LED lamp glowing and<br />

8 6/10/2011 12854 22873 ET WCR<br />

LP exp. DJ tripped through QSIT relay. Put HBA Off and check all also noticed that smoke emission from CP‐1. ET shed report:<br />

Compressor/Exhaust<br />

safety relay found no relay traget dropped. Smoke emission Loco tripped with QSIT. on checking found smoke emission<br />

er<br />

from CP‐1, hence CP‐1 isolated<br />

from CP‐1. further found CP‐1 burnt same replaced. ( Elgi make<br />

modified CP).<br />

Investigation report: GR and TFP safety valve both were<br />

blown. Oil spread over surrounding area near the GR and top of<br />

the conservator tank. Burnt GR oil was spread over and caused<br />

9 6/12/2011 12834 22263 SRC SER<br />

burning of insulation of cables and cleating sheath near the GR,<br />

LP reported that before N/section loco tripped with detonating<br />

TFP and RSI. The other equipment were not affected by fire.<br />

sound with heavy smoke in HT compartment and QLM dropped.<br />

Safety valve of GR and TFP blown due to GR inner insulating<br />

N/S passed on coasting & stopped train near KDTR H/sig<br />

ring (make BT.Mfg. year 2008) was broken, causing flashing in<br />

,checked & found heavy flame & smoke in HT compartment. so<br />

between even contacts 28‐20 which causes heavy circulating<br />

lowered panto & used F/extinguishers but fire could not control.<br />

current in the auto winding of tranformer which in turn<br />

LP demanded fire ‐brigade. CLI/RIG ‐S Parida found QLM in<br />

increase the temperature of oil and oil burnt .TFP winding got<br />

dropped condition.<br />

bulge and causing TFP safety valve blown. The GR insulating<br />

GR<br />

ring was replace during IOH in September,2009. This ring was<br />

part of the standard IOH kit. TFP make: CGL commissioning<br />

date: 18.01.1999.<br />

BIA Shed report: QLM relay in normal condition TFP and GR<br />

10 6/13/2011 18236 21289 BIA<br />

safety valve normal no any abnormality. DGA value CO 8.74<br />

LP reported that loco tripped before passing neutral section and<br />

CH4 .35 CO2 180.23 QLM relay tested found pickup 6.4 amp,<br />

SECR section cleared by coasting . Checked & found QLM dropped<br />

coil value .03. OHM Make: ‐ ALL SR no: ‐ WCM 080C0047 NR<br />

without oil splashed. so loco marked TR.<br />

found on 30 notch in both CAB. TFP make : ‐BHEL MFD: ‐1993<br />

Transformer<br />

SR no: ‐2008070. TFP under observation.<br />

LP informed that after EOT, while performing continuity test BIA shed report: Cab‐1 side BP addition cock partially open<br />

11 6/13/2011 58219 20540 BIA<br />

found BP neither creating nor dropping from Cab‐1but from cab‐.Thus BP charging and discharging from cab‐2 slowly. A‐9<br />

SECR<br />

2 creating and droping normal. At SDL SSE/SDL Changed cab‐1 changed at SDL checked found heavy leakage due to filter<br />

Pneumatic Valves<br />

A9 but trouble could not rectified. so loco marked TR. deficient and dust found on seating.<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Defective Material<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

SECR<br />

SECR<br />

SECR<br />

SECR<br />

SECR<br />

SECR<br />

SECR<br />

SECR<br />

SECR

SSE Shri P.K.Singh and CLI Shri R.S. Ram checked jointly at SDL<br />

and found CTF‐1,2,3, J 1,2 & C‐145 all in normal direction.<br />

LP exp.TLTE & LSB glowing. LP checked J‐1 &J‐2,CTF's & C‐145<br />

After detaching power at SDL Yd. on standing condition<br />

12 6/14/2011 51606 28217 BZA SCR but could not rectified.so train stopped & R/Loco demanded.<br />

operated MP towards braking direction LSB extinguised.<br />

Further try towards forward dirction. trouble vanised. <br />

Control Circuit<br />

Bad Maintanance<br />

Shed<br />

SECR<br />

13 6/14/2011 N/BIA 27925/27935 BIA<br />

LP reported that train stalled at km no‐587/29 due to loco<br />

trouble. checked & found rear loco 27935 notch not progressing<br />

at all. Manually operated GR from '0' to 10 & 10 to' 0'.Also BIA Shed report: Loco no. 27935‐SMGR stuck up due to sector<br />

SECR<br />

operated SMGR few times further notch progressing normal.but lever guide pin worn out. SMGR make‐BT<br />

again found same trouble .(LSGR Ext. in leading loco even rear<br />

loco notch not progressing).<br />

Loco jointly checked at trip shed AQ and found cab‐2 RA wire<br />

LP reported that after passing KAV east cabin train stopped due no. 984 on switch board‐2 fitted on 700 no. wire. same<br />

14 6/17/2011 12106 22212 BSL CR<br />

to CCPT melting (HOBA off previously). LP put ZPT on '0' and removed from cab‐2 switch board. And found CCPT holding and<br />

HBA off then replaced CCPT but as soon as put HBA kept "ON" also HOBA kept normal but loco having ‐ve bonding which is<br />

again CCPT melted. demanded R/Loco.<br />

under investigation.<br />

NOTE: Loco was taken over ex CR with HOBA off position.<br />

15 6/18/2011 N/BOX 24502 JHS NCR<br />

BIA shed report: Cable no. L‐967 earthed near HVSI‐2 (Blower<br />

LP reported that loco tripped, message found DJ tripped<br />

motor for cooling RSI‐2 block) terminal. 40 mm bolt provided<br />

through QSIT. put HBA off, check all auxiliaries and change<br />

in RSI‐2 bottom cover found broken. bolt changed. SIV working<br />

position of HRAVT.<br />

normal.<br />

LP reported that rear loco 27698 tripped and further found ICDJ.<br />

16 6/18/2011 N/KPKD 27846/27698 BIA<br />

LP could not rectified and demanded R/loco. LP again reported<br />

SECR<br />

LI Shri S.Parida HOBA made normal and found no trouble.<br />

that on further checking found in rear loco CCPT melted and<br />

melting repeatedly .Put HOBA off and loco energised.<br />

SMGR<br />

Control Circuit<br />

HT\LT cables<br />

Misc/Crew<br />

Defective Material<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Mal Operation by<br />

crew<br />

SECR<br />

SECR<br />

SECR<br />

SECR<br />

17 6/20/2011 12855 21343 BIA<br />

CLI Shri M.S.Arif found tripping through OP‐'B'. but putting<br />

LP exp tripping with out any relay target dropping. LP try to HPH, HVSL‐1 & 2 ON III and HQCVAR on '0' found no tripping,<br />

close DJ and found while closing BLVMT but after 15 seconds for probability of Q‐30 deffective so press BLRDJ continuously<br />

SECR<br />

again trips. On checking found C‐105 not closing. LP operate but DJ not closing. AQ shed report: Q‐30 relay is good but<br />

manually C‐105 few times and try but same trouble.<br />

resistance open circuited due to which Q‐30 is not energised<br />

and Q‐44 is not maintained.<br />

18 6/20/2011 N/BOX 23572/23279 BSL CR<br />

SE/SDL Shri V. Sharma checked found battery voltage showing<br />

LP informed from GGT that L/Loco 23572 tripped on standing &<br />

100 v, but baby compressor not start. further checked<br />

panto lowered. Checked CCBA ,CCPT both in Good condition. BA<br />

additional CCBA cable no‐ 003 feed available but rotating<br />

voltage normal, suspected BA feed not reaching in circuit. So<br />

switch board cable no‐ 003 feed not available due to cable noparalleling<br />

done from rear loco 23279. Then Panto rasied & DJ<br />

003 cut between additional CCBA to rotating switch board, so<br />

closed but L/cab‐2 H/Light not glowing. So worked the train in<br />

loco no. 23572 marked TR & loco directed to H/Shed for further<br />

40 kmph upto SDL.<br />

checking. Off IC/IA‐20/08/2011.<br />

LP kept switch no‐152 on one (failure mode) then found loco<br />

19 6/21/2011 N/KPKD 31233 LGD SCR<br />

Train left ROB at 0.50 hrs after detaching BE Loco 27133 from<br />

ready but due to up gradient (1/150) & drizzling rain LP<br />

M/Line. At km no‐615/11 train stopped due to throttle failed.<br />

experience wheel slipping. Hence R/Loco demanded.<br />

20 6/21/2011 N/BRS 27887/27982 VSKP<br />

Further found Q‐45 relay of both loco in energise condition.<br />

LP informed from BJRI that DJ closing directly while closing<br />

same removed & checked found Q‐30 relay burnt condition in<br />

ECoR BLDJ. SSE/SDL Loco no‐27887/982 checked & found DJ is closing<br />

both loco.hence both loco mark TR & directed to H/Shed for<br />

by pressing BLDJ.<br />

further checking.<br />

LP inform that while entering H/signal of UMR, GR not<br />

progressing beyond one notch. hence section cleared with SSE/BSP checked found HMCS‐1 on IV (privious booking). Q‐52<br />

21 6/21/2011 18235 21365 BIA<br />

mannual control of GR to UMR. At UMR try to rectified but weged in de‐energised condition. Loco tested with Q‐52 is<br />

SECR<br />

could not successful. also try from rear cab, EEC & also checked wedged and deweged conditon. Found no trouble. Tested from<br />

with all position of both HMCS ,but not successful hence both cabs and EEC. Loco found normal.<br />

demanded R/loco.<br />

Relay<br />

HT\LT cables<br />

Three phase loco<br />

Relay<br />

Relay<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

SECR<br />

SECR<br />

SECR<br />

SECR<br />

SECR

22 6/22/2011 N/BTMT 24552/24551 BIA<br />

BIA shed report: BA voltage in 24552, 24 V and hence both<br />

While starting LP exp DJ closing but STC not picking up. LP tried loco DJ not closing from 24552. But from loco no 24551 DJ<br />

SECR to rectify by keeping HBA off, but trouble not rectified.R/loco closing but not closing in 24552. Loco BA discharge in yard.<br />

demanded. So loco marked TR.<br />

Battery charger working checked found normal. Battery Make‐<br />

EXIDE<br />

M/staff attended but could not rectify and advised LP that loco<br />

23 6/22/2011 N/KRPH 27055 MGS ECR<br />

O/G‐ LP reported that while taken over charge of LE. poor brake has to go to pit to attend, brake power adjusted in pit and<br />

power.<br />

given fit. LP reported TLC at 23.30 hrs that no information by<br />

I/C LP.<br />

24 6/27/2011 12860 22504 SRC SER<br />

LP informed that QOP‐II permanently dropped so block‐II AT Igatpuri M/staff found J‐2 drum contact badly flashed.and<br />

isolated and worked the train up to DGG. At DGG another loco TM‐4,5 & 6 badly flashed.SRC shed report: TM‐4 & TM‐5<br />

27934(VSKP) attached on top.<br />

commutator brush box flashed so Both TMs changed.<br />

25 6/30/2011 12860 22586 SRC SER<br />

1 11/6/2011 12253 22372 HWH ER<br />

1 04.06.11 12833<br />

AD‐HWH<br />

2 14.06.11 2962<br />

IND‐BCT<br />

3 15.06.11 12953<br />

BCT‐NZM<br />

LP reported that TLTE between JMG‐KRL, checked Q‐51, Q‐52,<br />

GR pressure found normal then try with EEC but unsuccess.<br />

CLI/ RIG‐ N Sahoo cleaned the Q‐52 relay and gently tapped<br />

and try to take 4‐5 notches found no trouble but R/loco already<br />

attached in front so as per advice of Sr. DEE (OP) allowed that<br />

24414/BZA ( 80 kmph ) + wkg loco in dead. SRC Shed report: Q‐<br />

52 defective. same changed.<br />

Battery<br />

Bogie & its Mech.<br />

Equipments<br />

Traction Motor<br />

Relay<br />

Mal Operation by<br />

crew<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Bad Maintanance<br />

Shed<br />

Suddenly pressure dropped at YPR station due to FP pipe already Suddenly pressure dropped at YPR station due to FP pipe already<br />

SWR<br />

broken and damaged due to CRO in BZA division, found BP also cracked broken and damaged due to CRO in BZA division, found BP also Pn. Pipeline<br />

Misc<br />

from neck portion.<br />

cracked from neck portion.<br />

22601 SRC SER LP INFORMED DJ OPEN ON STANDING W/O TARGET , CHECKED FOUND MICROPROCESSOR PT WAS OPEN CIRCUITED RESULTING INTO MICROPROCESSOR SRC/SER WR<br />

SMOKE NEAR BV BOX. FRESH LOCO PROVIDED.<br />

QCVAR NOT ENERGISING & R118 OVER HEATED. LOCO SENT DEAD TO<br />

HOME SHED.<br />

22542 BRC WR AFTER PASSING SBPJ DJ TRIPPED, CHECKED FOUND X'MER OIL SPREAD SECTION CLEAR AND FRESH LOCO PROVIDED. X'MER BRC<br />

WR<br />

OUT AND OIL LEVEL MINIMUM.<br />

SHED<br />

30025 GZB NR TRAIN STOPPED AS TWO FAULT EXPEERIENCE BY LOCO PILOT F0201P1 IN RTM SHED FOUND TM 1 JAMMED.HENCE STARS (GEAR) TM END &<br />

i.e. DISTURBANCE IN CONVERTOR NO.1 AND F0201P2 i.e.EARTH FAULT GEAR CASE UNCOUPLED & SR‐1 ISOLATED BY GZB STAFF. LOCO SENT<br />

IN CONVERTOR NO.1 . AND SMOKE NOTICED FROM TM‐1.<br />

LELA WITH SR. 90 KMPH TO HOME SHED.<br />

THREE PHASE<br />

GZB<br />

NR<br />

SECR<br />

SECR<br />

SECR<br />

SECR<br />

WR<br />

4 29.06.11 GM/KWI<br />

43/3960<br />

2 03.06.11 23024+24459<br />

BL/WR(DEAD)<br />

23089 TKD WCR TRAIN STOPPED AT KM 286/20 DUE TO DJ TRIP BY QSIT WHILE BLDJ<br />

PRESSED WITH MESSAGE "INVERTER FAULTY". HBA KEPT OFF, HSIV<br />

KEPT ON "0" BUT NOT SUCCEEDED. FRESH LOCO 24528 PROVIDED.<br />

SI‐AAL, MICROPROCESSOR‐STESALIT.<br />

ET WCR LOCO WAS ORDERED EX ELS/ET. AFTER EOL LP NOT START &<br />

REPORTED QRSI‐2 DROPPING ON 4tH NOTCH HENCE LINE CLEAR<br />

CANCELLED. ELS STAFF REACHED ON LOCO & GIVEN READY AFTER<br />

INCREASING SETTING OF QRSI & TRAIN LEFT EX ET YARD. LP AGAIN<br />

REPORTED EX ET THAT QRSI‐2 DROPPING ON 800 AMP. LATER TRAIN<br />

PASSED BNI VIA LOOP LINE WITH BANKER LOCO 23817/NR BUT<br />

STOPPED NEAR ADVANCE STARTER DUE TO QRSI‐2 DROPPING HENE<br />

TRAIN BACK TO BNI LOOP LINE DUE TO GRADIENT AHEAD & LOCO<br />

FAILED & SENT TO T/S ET.<br />

AT BRC SHED JOINTLY CHECKED WITH AAL REPRESENTATIVE AND<br />

FOUND "IGDU‐VFD" RECORDED IN FAULT MEMORY OF SIV. ON<br />

FURTHER CHECKING FOUND V‐PHASE LEFT SIDE IGBT SHORT<br />

CIRCUITED. LOCO UNDER OBSERVATION AFTER IGBT CARD<br />

REPLACEMENT.<br />

SI UNIT<br />

LOCO JOINTLY CHECKED BY SLI & JE & REPORTED 01 CT (CURRENT<br />

TFP) USING AS RSI‐LM TWO CT, ONE USED IN THIS LOCO WHICH IS<br />

PARALLEL CONNECTED (ONE CT IN RSI‐2 BLOCK & ONE ADDITIONAL<br />

CT USE IN BA‐3 PANEL BETWEEN WIRE NO. A‐274 & A‐275 CAUSING<br />

QRSI‐2 DROPPING ON 800 AMPS.<br />

RESPONSIBILITY BAD WORKMANSHIP OF ELS/ET DURING<br />

UNSCHEDULE REPAIR & WRONG CONNECTION MADE TWO CT OF RSI‐<br />

2. ELS/ET REPORT‐ LOCO CHECKED AT T/S ET & FOUND QRSI‐2<br />

DROPPING ON 3rd NOTCH AT 700 AMPS CURRENT. QRSI‐2 RELAY COIL<br />

WIRE NO. A/274 & A/275 SHOWING SHORTED, EVEN AFTER BOTH<br />

SIDE CONNECTION WAS REMOVED. FURTHER DURING CHECKING<br />

FOUND 02 NOS CT IS EXISTING IN RSI‐2, WHILE IN BA‐2 & 3 02 NOS RSI<br />

CT WAS ALSO EXISTING, WHICH RESULTED TOTAL CURRENT IN QRSI<br />

RELAY INCREASED. RSI WAS LAST CHANGED ON 02.06.11.<br />

RSI MAINT WCR<br />

TKD<br />

WCR<br />

WR

3 04.06.11 20686 ET WCR LP REPORTED NEAR MKRN HOME SIGNAL, QLM & QRSI‐2 DROPPED &<br />

CCBA & CCPT FUSE MELTED. SECTION CLEARED IN ROLLING. SAME<br />

ELS/ET REPORT‐ LOCO CHECKED & FOUND (1) QPDJ RELAY<br />

SUPPORTING ROD WELDING BORKEN & ITS LT WIRE DROPPED ON<br />

TIME LP REPORTED IN QRSI‐2 RELAY BLOCK FLASHED & DJ NOT CLOSED RGR. SINCE LT WIRE NO. 738, 739 OF QPDJ TRACKED WITH RGR, QRSI‐<br />

HENCE LOCO FAILED & DEMANDED ASSISTING LOCO. ANOTHER LOCO 2 I/LOCK BADLY FLASHED & CARBONIZED HENCE DJ WASNOT CLOSED.<br />

23799/NR SENT EX GW & AFTER EOL ON TOP, TRAIN LEFT. SLI CHECKED (2) DUE TO BA‐2 HT JALLI FIXING BRACKET ONE NO. BOLT BROKEN &<br />

& REPORTED CURRENT TRANSFORMER WIRE NO. 738 & 739 FLASHED<br />

& TOUCHED WITH BODY (NEAR HT). FAILED LOCO SENT TO T/S NKJ.<br />

OTHER ONE FOUND DEFICIENT, "Z" BRACKET FOR SMGR SUPPORTING<br />