Sustainable Tree Management for Charcoal Production ... - Pisces

Sustainable Tree Management for Charcoal Production ... - Pisces

Sustainable Tree Management for Charcoal Production ... - Pisces

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

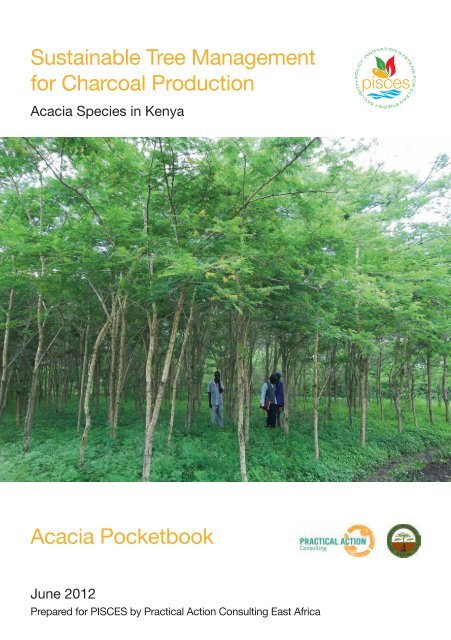

<strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong><br />

<strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong><br />

Acacia Species in Kenya<br />

Acacia Pocketbook<br />

June 2012<br />

Prepared <strong>for</strong> PISCES by Practical Action Consulting East Africa

Although this research is funded by DFID, the views expressed in this<br />

report are entirely those of the authors and do not necessarily represent<br />

DFID’s own policies or views. Any discussion of their content should<br />

there<strong>for</strong>e be addressed to the authors and not to DFID.<br />

Authors: Nellie M. Oduor (Kenya Forestry Research Institute - KEFRI),<br />

Wairimu Ngugi and Tameezan wa Gathui (Practical Action<br />

Consulting East Africa - PAC EA).<br />

Editors: Ewan Bloomfield and Katie Wel<strong>for</strong>d (PAC UK); Hannah Wanjiru<br />

(PAC EA).<br />

Cover images: Main: Acacia polyacantha woodlot at 2½ years (spacing<br />

2.5 x 2.5 metres) in Rarieda, Nyanza (Wairimu Ngugi/PAC).<br />

All images: Practical Action Consulting, unless otherwise stated.<br />

Abbreviations<br />

ACTS African Centre <strong>for</strong> Technology Studies<br />

DFID Department <strong>for</strong> International Development<br />

FAO Food and Agriculture Organisation<br />

g/cm3 Grams per cubic metre<br />

KFS Kenya Forest Service<br />

KEFRI Kenya Forestry Research Institute<br />

kj/g Kilojoules per gram<br />

Ksh Kenya shilling<br />

PAC Practical Action Consulting<br />

PISCES Policy Innovation Systems <strong>for</strong> Clean Energy Security<br />

UK United Kingdom<br />

UN United Nations<br />

US$ United States Dollar<br />

Acknowledgements<br />

This publication was prepared through a participatory process led by PAC and KEFRI<br />

through the Policy Innovation Systems <strong>for</strong> Clean Energy Security (PISCES) project. PAC<br />

and KEFRI appreciate various stakeholders who have shared their practical experiences<br />

on feedstock management <strong>for</strong> charcoal production. We also thank various stakeholders<br />

<strong>for</strong> their collaboration especially Dr. Joseph Githiomi (Centre Director, KEFRI Forest<br />

Products Research Centre Karura); Kenya Forest Service (KFS), PAC UK, Practical Action<br />

Regional Office <strong>for</strong> East Africa and International Network on Gender and <strong>Sustainable</strong><br />

Energy (ENERGIA – Kenya Network).<br />

2 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong><br />

Contents<br />

Acknowledgements 2<br />

Acronyms and Abbreviations 2<br />

Introduction 4<br />

Species Selection <strong>for</strong> <strong>Sustainable</strong> <strong>Charcoal</strong> <strong>Production</strong> 5<br />

Species choice in Kenya 5<br />

Suitable woody species <strong>for</strong> woodfuel in Kenya 6<br />

Characteristics of Acacias 6<br />

Calorific value of wood 7<br />

<strong>Tree</strong> Farming and <strong>Management</strong> Practices 8<br />

Basic inputs <strong>for</strong> tree farming 8<br />

Seed collection and storage 8<br />

Certified seeds 9<br />

Farm preparation 9<br />

Seed treatment and sowing 10<br />

Steps in seedling planting 10<br />

<strong>Tree</strong> management practices 11<br />

<strong>Tree</strong> harvesting techniques, tools and implements 12<br />

Processing Technologies 14<br />

Methods of charcoal production 14<br />

Casamance kiln 14<br />

The half orange kiln 14<br />

The meko kiln 15<br />

The drum kiln 15<br />

How to use the drum kiln 16<br />

Gender equity <strong>for</strong> sustainable charcoal production 17<br />

References 18<br />

Appendices 20<br />

Appendix 1: List of KEFRI Regional Centres and Sub Centres 20<br />

Appendix 2: List of KEFRI Approved <strong>Tree</strong> Seed Stockists 21<br />

<strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 3

Introduction<br />

This publication shares in<strong>for</strong>mation on tree growing and management <strong>for</strong> sustainable<br />

charcoal production. It focuses on Acacia species with emphasis on Acacia<br />

polyacantha and Acacia xanthophloea. Both species are native to a majority of<br />

the arid and semi-arid areas in Kenya, including parts of Bondo, western Kenya,<br />

where Practical Action is undertaking much of its work on sustainable charcoal.<br />

The publication also highlights the importance of promoting gender equity as a vital<br />

component <strong>for</strong> supporting grassroots communities to achieve sustainable charcoal<br />

production through fair sharing of resources and benefits by both men and women.<br />

The publication has been developed through a participatory process led by PAC and<br />

KEFRI through PISCES project. It seeks to support implementation of the current<br />

charcoal policy and compliance requirements and is part of a series of publications<br />

developed by PISCES to create awareness on the Forest (<strong>Charcoal</strong>) Rules, 2009.<br />

<strong>Charcoal</strong> is a key bioenergy resource and source of energy in Kenya, providing<br />

82 percent of urban and 34 percent of rural household energy, employment<br />

and income <strong>for</strong> over 700,000 people who support over two million dependants.<br />

Demand <strong>for</strong> charcoal is fast increasing due to population growth, increased<br />

urbanization and the development of cottage industries.<br />

<strong>Charcoal</strong> is produced from trees grown in <strong>for</strong>ests, woodlands, bush lands,<br />

grasslands, farmlands and plantations. Although the Energy and Forestry Policies<br />

and Acts have recently legalized sustainable charcoal production, numerous<br />

challenges still affect the industry, while its true value is not adequately captured<br />

in national economic statistics. Increased charcoal consumption and the use of<br />

traditional kilns have resulted in increased destruction and depletion of national<br />

tree resources. For example every tonne of charcoal produced through a traditional<br />

kiln depletes approximately 0.1 hectare of woodland. An efficient kiln would require<br />

only 0.05 hectares <strong>for</strong> every tonne of charcoal produced, a 50% saving. This<br />

calls <strong>for</strong> tree growing aimed at sustainable on-farm / community level charcoal<br />

production and widespread adoption of efficient wood conversion technologies.<br />

<strong>Tree</strong> growing <strong>for</strong> charcoal production at the farm / community level involves<br />

both men and women in different roles and responsibilities and with different<br />

levels of access to and control over production resources including land, water,<br />

labour and financial inputs. Men and women also have different levels of access<br />

and control over benefits derived from charcoal production. This necessitates<br />

awareness creation and in<strong>for</strong>mation sharing on the need <strong>for</strong> gender equity as a<br />

vital component of promoting sustainable charcoal production.<br />

Species Selection <strong>for</strong> <strong>Sustainable</strong><br />

<strong>Charcoal</strong> <strong>Production</strong><br />

Species choice in Kenya<br />

Species selection, climatic conditions, tree growth rate and management<br />

practices are some of the most critical factors in sustainable charcoal<br />

production. Generally, all species of wood can be carbonized to produce<br />

charcoal. However, the quality of charcoal varies from species to species and<br />

the method of carbonisation.<br />

Species that produce high quality charcoal include Casuarina equisetifolia, Acacia<br />

mearnsii, Acacia polyacantha, Acacia xanthophloea, Acacia spectabilis, Eucalyptus<br />

camaldulensis, Leuceana leucocephala, Tectona grandis, Sesbania sesban and other<br />

Acacia and Combretum species. These species are preferred mostly because they<br />

produce heavy charcoal that burns <strong>for</strong> a long time, making it economical to use.<br />

Characteristics of tree species which are suitable <strong>for</strong> wood fuel production<br />

• Grow quickly, yield a high volume of wood quickly, and require minimum<br />

management time.<br />

• Coppice or sprout well from shoots.<br />

• Have dense wood with low moisture content.<br />

• Produce little and non-toxic smoke.<br />

• Produce wood that splits easily and can easily be transported.<br />

• Produce wood without thorns.*<br />

• Yield other products or services <strong>for</strong> the household.<br />

• Produce wood that does not spit or spark when burning.<br />

Source: Hines and Eckman (1993)<br />

*However there are many thorny tree species that are suitable <strong>for</strong> woodfuel production,<br />

<strong>for</strong> example Acacia polyacantha and Acacia xanthophloea, among others.<br />

A farmer with 6 – 10 hectares of land can produce charcoal on a sustainable<br />

basis by harvesting a hectare every year <strong>for</strong> a rotation age of six years. Every<br />

year one hectare will be harvested and similarly one hectare planted with the<br />

same tree species.<br />

4 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 5

Suitable woody species <strong>for</strong> wood fuel in Kenya<br />

Acacia brevispica<br />

Acacia bussei<br />

Acacia drepanolobium<br />

Acacia gerardii<br />

Acacia hockii<br />

Acacia lahai<br />

Acacia mellifera<br />

Acacia nilotica<br />

Acacia nubica<br />

Acacia reficiens<br />

Acacia senegal<br />

Acacia seyal<br />

Acacia tortilis<br />

Acacia xanthophloea<br />

Afzelia quanzensis<br />

Albizia amara<br />

Albizia anthelmintica<br />

Balanites aegyptiaca<br />

Barleria spinisepala<br />

Bauhinia taitensis<br />

Boscia angustifolia<br />

Combretum apiculata<br />

Combretum brownii<br />

Combretum constrictum<br />

Combretum hereroensii<br />

Combretum molle<br />

Commiphora africana<br />

Terminalia spinosa<br />

Sources: Kareko, K. K. and Githiomi, J. (2000); Barklund, E. and Palmstiema, M. (2005).<br />

Characteristics of Acacias<br />

Commiphora schimperi<br />

Croton dichogamus<br />

Dalbergia melanoxylon<br />

Euclea divinorum<br />

Grewia bicolor<br />

Grewia plagiophylla<br />

Grewia similis<br />

Grewia vilosa<br />

Maytenus species<br />

Olea europaea variant africana<br />

Prosopis juliflora<br />

Prosopis pallida<br />

Tarchonanthus camphoratus<br />

Terminalia brownii<br />

Acacia is a pod-bearing group of shrubs and trees that tend to be thorny, hence<br />

they are also known as thorn-trees. Acacias are also known as wattles, including<br />

the yellow-fever acacia and umbrella acacias. There are roughly 1,300 species of<br />

Acacia worldwide, about 960 of which are native to Australia, with the remainder<br />

spread around the tropical to warm temperate regions of both hemispheres,<br />

including Africa, southern Asia, and the Americas.<br />

One of the fastest growing thorn trees is Acacia xanthophloea, a large tree that<br />

is 15 to 25 metres tall with a growth rate of 1 to 1.5 metres per year. The bark<br />

is smooth, slightly flaking and yellow to greenish-yellow. It is found in semievergreen<br />

bushland and woodland in areas with a high groundwater table and<br />

sandy soils. The species can withstand cold and is found at altitudes ranging<br />

from 600 – 2100 metres. One cubic metre of Acacia xanthophloea wood<br />

produces three bags of charcoal.<br />

Acacia polyacantha is a large deciduous tree that grows up to a height of 3.5 to<br />

20 metres; the bark is yellow-brown and inclined to be thick or peeling in thick,<br />

corky flakes and loose strips. It grows in wooded grasslands, woodlands and<br />

bushlands, thriving in sites with high groundwater table and alluvial soils with a<br />

good mix of clay and sand. The species grows from sea level to an altitude of<br />

1800 metres and does well with a mean annual rainfall of 300 - 1000 millimetres.<br />

Calorific value of wood<br />

The calorific value <strong>for</strong> wood ranges from 3.5 to 5 kilojoules per gram (kj/g) and<br />

<strong>for</strong> charcoal it ranges between 5 to 9 kj/g. Calorific value is the amount of heat<br />

produced by the complete combustion of a fuel. The value is used to determine<br />

the efficiency and effectiveness of different types of fuels. Calorific value is<br />

measured in units of energy per quantity of fuel, e.g. kg/g, while density of wood<br />

is the weight of wood per volume, e.g. grams per cubic metre (g/cm 3 ).<br />

Calorific value of wood and charcoal from selected tree species<br />

Species Density of the wood<br />

(g/cm 3 )<br />

Calorific value of wood<br />

(kj/g)<br />

Calorific value of<br />

charcoal (kj/g)<br />

Acacia mearnsii 0.775 3.7 7.4<br />

Acacia nilotica 0.624 4.9 7.3<br />

Acacia polyacantha 0.467 4.0 6.5<br />

Acacia xanthophloea 0.532 4.4 7.9<br />

Casuarina equisetifolia 0.820 5.0 7.7<br />

Commiphora africana 0.331 4.8 6.9<br />

Commiphora baluensis 0.541 4.4 6.6<br />

Commiphora campestris 0.388 4.2 6.9<br />

Eucalyptus grandis 0.790 4.5 7.5<br />

Eucalyptus maculata 0.603 – 7.4<br />

Grevillea robusta 0.530 – 7.2<br />

Markhamia lutea 0.356 – 8.1<br />

Senna spectabilis 0.337 – 8.0<br />

Terminalia brownii 0.445 4.6 7.3<br />

Terminalia orbicularis 0.685 5.1 5.9<br />

Prosopis juliflora 0.891 4.9 7.9<br />

Prospopis pallida 0.834 4.9 7.8<br />

Source: Oduor, Nellie M. (2005).<br />

6 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 7

<strong>Tree</strong> Farming and <strong>Management</strong> Practices<br />

Basic inputs <strong>for</strong> tree farming<br />

• Land and water.<br />

• Labour <strong>for</strong> land preparation.<br />

• <strong>Tree</strong> nursery (establishment and management).<br />

• Labour <strong>for</strong> tree planting, weeding and management.<br />

• <strong>Tree</strong> protection.<br />

Generally, trees require minimum inputs after planting compared to agricultural<br />

crops. However, weeding and protection against grazing, trampling and browsing<br />

by animals and trespass or destruction by humans is important <strong>for</strong> optimum yields.<br />

Other factors which affect successful establishment are fire, pests and diseases.<br />

Labour inputs <strong>for</strong> plantation establishment and management (especially <strong>for</strong> Acacia species)<br />

Activity Labour input in person days / hectare<br />

Clearing and land preparation 20<br />

Raising and transporting seedlings 4<br />

Planting 15<br />

Weeding and maintenance 24<br />

Source: Jurvélius, M. (1997).<br />

Seed collection and storage<br />

Flowering of most Acacias is dependent on the rains. The seeding period occurs<br />

approximately six months after flowering. On average Acacia xanthophloea<br />

produces 24,000 to 30,000 seeds per kilogramme while Acacia polyacantha<br />

produces 15,000 seeds per kilogramme.<br />

Tips on seed collection and storage<br />

• Collect mature brownish pods from the crowns of standing trees by shaking<br />

the branches to release the pods.<br />

• Split the pods by hands to obtain small quantities of seeds.<br />

• Store mature and properly dried seeds in airtight containers at room<br />

temperature <strong>for</strong> up to one year.<br />

Certified seeds<br />

Certified tree seeds are recommended <strong>for</strong> best germination results. Seed<br />

certification is a legally sanctioned and internationally recognized system <strong>for</strong><br />

quality control of seed multiplication and production. Certification ensures that<br />

tree growers have access to high quality seeds and propagating materials of<br />

known genetic identity and purity, with high germination rates and freedom from<br />

weed seeds. KEFRI, through its <strong>Tree</strong> Seed Programme is mandated to produce<br />

tree seeds that are collected from selected and approved tree sources. Certified<br />

tree seeds can be obtained from KEFRI Regional Centers and Sub-Centers<br />

distributed in Kenya as listed on Appendix 1. KEFRI has also contracted treeseed<br />

stockists in Kenya as listed on Appendix 2.<br />

Acacia Species Local price<br />

(Ksh)<br />

Approximate price per kilogramme of certified Acacia seeds<br />

Export price<br />

(US$)<br />

Acacia Species Local price<br />

(Ksh)<br />

Export<br />

price (US$)<br />

Acacia brevispica 1000 40 Acacia nilotica 800 40<br />

Acacia drepanolobium 1000 40 Acacia nubica 600 40<br />

Acacia elatior 1200 40 Acacia polyacantha 1500 40<br />

Acacia gerrardii 1000 40 Acacia reficiens 800 50<br />

Acacia hockii 800 40 Acacia senegal 1500 40<br />

Acacia lahai 600 40 Acacia seyal 1500 40<br />

Acacia mangium 1000 150 Acacia sieberiana 1000 40<br />

Acacia mearnsii 800 40 Acacia tortilis 1500 40<br />

Acacia melanoxylon 1000 50 Acacia xanthophloea 3000 40<br />

Acacia melifera 1500 50 Acacia zanzibarica 800 50<br />

Source: KEFRI (2010).<br />

8 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 9

Farm preparation<br />

• Site selection: Most Acacias are accustomed to drought in their native habitat<br />

and should be planted in areas with well-drained soil. If the soil is not well<br />

drained, the Acacia can be planted on a gentle slope or hill top. The majority<br />

of Acacias can grow in acidic, neutral or alkaline soils. For optimum growth,<br />

plant the Acacias in full sunlight.<br />

• Land preparation: Start land preparation be<strong>for</strong>e the onset of the rains to<br />

remove weeds. Weeds inverted during ploughing dry up and decompose,<br />

adding nutrients to the soil. Proper soil preparation ensures the soil surface<br />

and hard pans are broken to improve water infiltration, soil aeration and easy<br />

root penetration into the soil substrate.<br />

Seed treatment and sowing<br />

• Acacia seeds can be sown in seedling trays or directly in the field. To achieve<br />

high germination and seedling survival rates, establish the tree nursery or sow<br />

the seeds directly during the rainy season.<br />

• Pre-sowing treatment:<br />

• Nick the seed coat at the cotyledon end using a knife or any other sharp tool<br />

and sow immediately;<br />

or<br />

• Soak the seed in hot water, cool overnight and sow the next morning.<br />

• When sowing cover the seeds with a thin layer of sand and keep moist (water<br />

the seedling trays / beds during dry spells). Under ideal conditions germination<br />

occurs within 5 to 15 days <strong>for</strong> Acacia xanthophloea and 10 to 21 days <strong>for</strong><br />

Acacia polyacantha. The expected germination rate <strong>for</strong> mature, healthy and<br />

properly treated seed is 40% to 90% <strong>for</strong> Acacia xanthophloea and 60% to<br />

90% <strong>for</strong> Acacia polyacantha.<br />

Seedling planting and management<br />

• Start tree planting at the beginning of the long rains i.e. after approximately<br />

100 millimetres of steady rainfall.<br />

• Transplant seedlings after they have grown to the 2-leaf stage from seedling<br />

trays or nursery beds into nursery bags filled with a mixture of five parts river<br />

sand and one part compost (ratio of 5:1).<br />

• Spacing is the most important aspect in the establishment of <strong>for</strong>est plantations<br />

because it correlates to the success of the <strong>for</strong>est plantation in terms of<br />

maintenance, stand stability, quality of wood and investment. For short<br />

rotation <strong>for</strong>estry <strong>for</strong> charcoal production, a minimum of 2 metres by 2 metres<br />

spacing is recommended. Clear felling is recommended <strong>for</strong> tree rows that are<br />

more closely spaced (e.g. 1 metre by 1 metre) because the remaining trees if<br />

selectively harvested would be too weak or unstable to remain upright.<br />

Steps in seedling planting<br />

Step 1 Make a hole measuring 45 centimetres wide by 45 centimetres<br />

deep. Separate the top soil from the subsoil when digging the hole.<br />

Step 2 Mix the top soil with manure.<br />

Step 3 Place the seedling inside the hole and cover with the mixture of top<br />

soil and manure.<br />

Step 4 Gently firm the soil all around the roots.<br />

Step 5 After planting use the subsoil to make a basin <strong>for</strong> water retention<br />

around the seedling.<br />

Step 6 Water the seedling.<br />

• To achieve high survival rates tree seedlings should be planted during the rainy<br />

season when watering is not necessary. However, if possible watering should be<br />

done immediately after planting. If there is no rainfall during the first week after<br />

planting, watering is necessary <strong>for</strong> achievement of a survival rate of over 70%.<br />

• Beating up or replanting to replace any dead seedlings should be done either<br />

during the following planting season or when there is enough moisture build<br />

up in the soil.<br />

10 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 11

<strong>Tree</strong> management practices<br />

• Weeding: During the first two years, Acacias can be intercropped with<br />

agricultural crops such as maize, beans, groundnuts and chilli pepper. Besides<br />

reducing the cost of weeding this will ensure the trees benefit from weeding<br />

while the crops will in turn benefit from the nitrogen fixing qualities of Acacias.<br />

Regular spot weeding of 1 metre diameter around the seedling should be<br />

carried <strong>for</strong> trees that are not intercropped with agricultural crops to remove<br />

excessive vegetation until the trees <strong>for</strong>m a canopy.<br />

• Pests and disease control: Acacias contain organic compounds which act<br />

as natural repellents that defend / protect them against pests and grazing<br />

animals. The thorny nature of most Acacias is also a defence mechanism<br />

against browsing by animals. Some of the insect pests affecting trees in arid<br />

and semi-arid regions include termites, defoliators, sap suckers, seed and<br />

wood borer.<br />

• Coppicing: Leaving a short stump of a felled tree to encourage re-growth<br />

is known as coppicing. Re-growth from a cut tree stump or the base of a<br />

damaged stem is known as a ‘coppice’.<br />

To manage a coppice, select about four dominant branches and remove the<br />

other smaller/weaker branches. These can further be reduced to two or three<br />

branches within the year.<br />

Example of a coppicing Acacia polyacantha<br />

(Nellie M. Oduor, KEFRI)<br />

Labour inputs <strong>for</strong> plantation establishment and management (especially <strong>for</strong> Acacia species)<br />

Activity Labour input in person days / hectare<br />

Clearing and land preparation 20<br />

Raising and transporting seedlings 4<br />

Planting 15<br />

Weeding and maintenance 24<br />

Source: Jurvélius, M. (1997).<br />

Selected pests of Acacia species and control measures<br />

Host Pest Nature of attack Control measures<br />

Acacia nilotica Brichiduis baudoni Seed borer BHC fumigation<br />

Acacridium melanorhodon Defoliator Diazinon<br />

Pediosus species Seed borer BHC fumigation<br />

Acacia polyacantha Oemida gahani Wood borer Correct pruning<br />

Acacia seyal<br />

Acacia xanthophloea<br />

Triozastus baghaasi Wood borer BHC preservative<br />

Acacia tortilis Sphadasmus species Wood borer Diazinon<br />

Source: adapted from Muok et al., 2007.<br />

Bruchidius longipennis Defoliator BHC preservative<br />

Tips on pests and diseases control<br />

• Carefully read and follow the label precautions and directions <strong>for</strong> all<br />

pesticides, fumigants, preservatives and other chemicals applied <strong>for</strong><br />

disease and pests control.<br />

• For further in<strong>for</strong>mation / assistance on tree pests and diseases control<br />

contact KEFRI Regional Centres and Sub-Centres, KFS County and<br />

Zonal Offices and authorised <strong>for</strong>estry and agricultural extension agents.<br />

12 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 13

<strong>Tree</strong> harvesting techniques, tools and implements<br />

Handling both Acacia xanthophloea and Acacia polyacantha requires the use of<br />

protective gear (e.g. boots and hand gloves) due to the thorny characteristics<br />

of these species, particularly the tops of Acacia xanthophloea and stems of<br />

Acacia polyacantha. <strong>Tree</strong> harvesting should be done using methods, tools and<br />

implements that minimise damage to the surrounding site and soil.<br />

Tools and implements <strong>for</strong> harvesting wood<br />

Description of tool or implement Purpose of tool or implement<br />

Wheel barrow Transportation of wood<br />

2-man crosscut saw (5-6’)* Wood cutting<br />

Professional bow saw, 36”* Wood cutting<br />

Logging axe Cutting of wood<br />

Whetstone Metal (tools) sharpening<br />

Machete, rake Clearing of biomass, branches<br />

Metal file, 6-10” Saw and other sharpening<br />

Safety helmet Head protection<br />

Steel toed safety boots Leg and feet protection<br />

First aid kit First aid<br />

Pair of working gloves Protection of hands<br />

Ladder Pollarding of branches of thorny trees<br />

*For harvesting plantation grown wood.<br />

Source: Adapted from Jurvélius, M. (1997).<br />

General rules <strong>for</strong> sustainable harvesting of <strong>for</strong>est plantations<br />

1 Harvest using methods that minimise damage to the planted site and surrounding soil.<br />

2 • Use chainsaws <strong>for</strong> big trees. For small trees use bow saws, cross-cut saws or handsaws.<br />

• Cut trees as low as possible and carefully control the felling direction<br />

(e.g. from uphill to the road into existing gaps).<br />

• Minimise the number of logging pathways and amount of movement inside the plantation.<br />

• Suspend logging during wet periods.<br />

3 • The use of animals such as donkeys to ferry harvested trees is ideal to minimise damage to the soil on<br />

steep slopes.<br />

• The use of a small farm tractor is possible on gentle slopes.<br />

• A portable sawmill can be used to saw up cut logs at the harvesting site.<br />

4 Stream side buffer strips of at least 20 metres on either side of the stream should be maintained.<br />

Source: Adapted from Maua, J. and Ngazi, J. (2009).<br />

Processing Technologies<br />

Methods of charcoal production<br />

The three most common methods of charcoal production are earth kilns,<br />

masonry kilns and metal kilns.<br />

• Earth kilns are of various types but the most common are the traditional earth<br />

kiln, improved earth kiln and the Casamance kiln.<br />

• Masonry kilns are usually of the beehive and half orange type; they are<br />

recommended <strong>for</strong> charcoal conversion in areas where fuelwood is available<br />

<strong>for</strong> prolonged periods, such as in large-scale land clearing or in fuelwood<br />

plantations.<br />

• Metal kilns include the drum kiln, meko kiln and Mark V type.<br />

Casamance kiln<br />

The kiln has a chimney at the back and air-lets or channels at the side. The wood<br />

is cut into pieces measuring 0.5 metres long which are arranged upright and<br />

covered, first with grass or foliage and then soil be<strong>for</strong>e lighting. Carbonisation<br />

takes 2-3 days depending on the size of kiln.<br />

Left: Wood arranged upright <strong>for</strong> Casamance kiln<br />

(Nellie M. Oduor, KEFRI)<br />

Right: Lighting the Casamance kiln after covering the<br />

wood. The metal chimney is visible at the back of the<br />

kiln (Nellie M. Oduor, KEFRI).<br />

14 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 15

The half orange kiln<br />

The kiln is made of brick and covered <strong>for</strong> protection from rain. The wood is<br />

packed inside the kiln through a doorway, which is then sealed halfway up.<br />

The wood is lit and once it has caught fire the doorway is completely sealed.<br />

Carbonisation takes 2 to 3 days depending on the size of kiln.<br />

Left to right: Wood arranged tightly inside the half orange kiln, and sealing the door way of the kiln<br />

(Nellie M. Oduor, KEFRI).<br />

The meko kiln<br />

A new meko kiln belonging to Masanga Women Group<br />

in Madiany, Bondo (PAC).<br />

This is a modified drum that has two<br />

chambers and two metal doors; the<br />

inner chamber is <strong>for</strong> carbonization<br />

while the outer chamber is <strong>for</strong> firing.<br />

The wood is cut into pieces measuring<br />

0.8 metres long and packed into the<br />

modified drum kiln. After closing the<br />

doorway of the inner chamber the<br />

wood in the outer chamber is lit and<br />

the kiln’s metal door is closed. The<br />

carbonization process takes 10 hours<br />

while cooling takes 3 hours.<br />

The drum kiln<br />

The drum kiln is made from an ordinary<br />

oil drum. The kiln has a removable lid<br />

and a detachable metal ring which<br />

joins the lid to the drum. The ring has<br />

an adjustable screw which tightens the<br />

lid to the drum. The drum is modified<br />

by welding a short metal pipe that<br />

acts as a chimney onto the drum.<br />

The bottom side of the chimney has a<br />

diameter of 6 centimetres. A separate<br />

metal grill is constructed to fit inside<br />

the bottom of the kiln. The metal grill<br />

prevents fuelwood from touching the<br />

bottom of the drum, thus providing<br />

air circulation within the kiln during the<br />

process of carbonisation.<br />

A drum kiln with feedstock (KFS).<br />

The carbonization process takes 6 to 12 hours giving a charcoal recovery rate of<br />

32% to 38% which is 3 to 4 times more than recovery from the traditional earth<br />

kiln. the drum kiln has a capacity of 0.4 cubic metres of wood and yields about<br />

3/4 of a bag of charcoal. It is most suitable <strong>for</strong> domestic charcoal production<br />

using small diameter stems or tree branches.<br />

16 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 17

How to use the drum kiln<br />

(Nellie M. Oduor, KEFRI).<br />

Step 1 Cut the wood into pieces measuring 80<br />

centimetres in length and split thicker logs into<br />

pieces measuring 6 to 10 centimetres in diameter.<br />

Step 2 Place the metal grill inside the kiln and stack<br />

dried wood onto the metal grill until the kiln is<br />

fully loaded.<br />

Step 3 Close the loaded drum with the lid which has a<br />

firing door and cover the kiln with soil, leaving<br />

the firing door uncovered.<br />

Step 4 Stack small pieces of wood at the firing section<br />

and light the kiln. Allow the wood pieces at the<br />

lighting section to burn until the wood inside<br />

the drum catches fire and the chimney starts<br />

emitting smoke.<br />

Step 5 Cover the firing door with soil.<br />

Step 6 Remove the chimney when clear blue smoke<br />

is emitted thus indicating the wood is fully<br />

carbonized.<br />

Step 7 Seal the chimney holder with grass and soil.<br />

Leave the drum to cool <strong>for</strong> 12-24 hours be<strong>for</strong>e<br />

removing the charcoal.<br />

Gender equity <strong>for</strong> sustainable charcoal production<br />

The aim of promoting gender equity is to ensure fair sharing of resources and<br />

benefits by both men and women involved in charcoal production, including<br />

raising tree seedlings, and the distribution and marketing process, particularly<br />

at the small-scale community level.<br />

The key issues to address in promoting gender equity in the charcoal sector<br />

include:<br />

• Cultural attitudes and barriers that inhibit women’s participation in decision<br />

making processes at the household and community levels. These barriers<br />

limit women’s access to and control over tree production resources such as<br />

land and labour. They also inhibit women’s ability to use and benefit from tree<br />

resources. For instance, due to the prevailing land tenure system in many<br />

Kenyan communities land is traditionally owned by men. Women have user<br />

rights to land but these rights are often determined by husbands or male<br />

relatives. This inhibits women’s access to land and water <strong>for</strong> tree production.<br />

Similarly, women have limited access to tree tenure.<br />

• Access to financial resources and credit <strong>for</strong> charcoal entrepreneurship<br />

determines the level of men and women’s participation in the charcoal sector.<br />

Land is often used as collateral <strong>for</strong> loan facilities. Lack of land ownership<br />

there<strong>for</strong>e limits women’s ability to access credit <strong>for</strong> investing in charcoal<br />

enterprise.<br />

• Gender roles and responsibilities at the community and household levels,<br />

which determine the division of labour thus impacting on men’s and women’s<br />

relationship to natural resources, e.g. access to labour <strong>for</strong> tree growing,<br />

charcoal production and marketing.<br />

Strategies <strong>for</strong> promoting gender equity in the charcoal sector include:<br />

• Awareness raising and in<strong>for</strong>mation sharing on the need <strong>for</strong> gender equity as a<br />

vital component of sustainable tree management <strong>for</strong> charcoal production;<br />

• Lobby and advocacy at the community and national levels to increase<br />

women’s access to and control over tree and charcoal production resources;<br />

• Establishment of small-scale revolving funds and credit facilities <strong>for</strong> charcoal<br />

producers to support resource poor farmers, especially women.<br />

18 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 19

References<br />

Barklund, E. and Palmstiema, M. (2005). <strong>Charcoal</strong> production and processing<br />

in Kenya: opportunities <strong>for</strong> improving supply. A RELMA and KEFRI Report.<br />

ESDA -Energy <strong>for</strong> <strong>Sustainable</strong> Development Africa (2005). National <strong>Charcoal</strong><br />

Survey: Exploring the potential <strong>for</strong> a sustainable charcoal industry in Kenya. A<br />

product of the Kenya <strong>Charcoal</strong> Working Group. June 2005. Pgs 74<br />

Delahunty, A. (2011). Gender Equity, <strong>Charcoal</strong> and the Value Chain in Western<br />

Kenya. PISCES Working Brief. Centre <strong>for</strong> African Studies, University of<br />

Edinburgh.<br />

ENERGIA – Kenya Network (2012). National Training Workshop on<br />

Mainstreaming Gender in Energy Projects in Kenya. Workshop Report. Practical<br />

Action East Africa Regional Office.<br />

FAO Forestry Paper 63, (1985). Industrial <strong>Charcoal</strong> Making. Mechanical Wood<br />

Products Branch, Forest Industries Division. Food and Agriculture Organisation<br />

(FAO) Forestry Department. FAO UN Rome 1985. www.fao.org/docrep<br />

Hines D.A. and Eckman, K. 1993). Indigenous multipurpose trees of Tanzania:<br />

uses and economic benefits <strong>for</strong> people. ISBN 0-9697075-0-9<br />

http://agritech.tnau.ac.in/seed_certification<br />

http://www.kefri.org/seed.aspx<br />

Jurvélius, M. (1997). Labour-intensive harvesting of tree plantations in the<br />

southern Philippines. Forest Harvesting Case-Study 9. Food and Agriculture<br />

Organization of The United Nations Bangkok, Thailand, 1997 http://www.fao.org/<br />

docrep/x5596E/x5596e00.htm#Contents<br />

Kareko, K. K. and Githiomi, J. (2000). National Arrangements and Capacity to<br />

Collect Wood Energy In<strong>for</strong>mation and Statistics: The Kenyan Scenario. Paper<br />

presented at FAO/UNEP Regional Workshop on Wood Energy In<strong>for</strong>mation in<br />

Africa, 23rd – 27th October, 2000 in Nairobi, Kenya.<br />

KEFRI (2010). Revised Seed Catalogue: Kenya Forestry Seed Centre. KEFRI Leaflet.<br />

KEFRI (2006). <strong>Charcoal</strong> <strong>Production</strong> using Improved Earth, Portable Metal, Drum<br />

and Casamance Kilns. KEFRI, Forest Products Research Centre, Karura.<br />

Maua, J., and Ngazi, J. (2009). Growing Acacia xanthophloea and Acacia<br />

polyacantha <strong>for</strong> charcoal in Madiany Division, Siaya County. A KEFRI Report.<br />

Mugo, F. and Ong, C. (2006). Lessons of eastern Africa’s unsustainable charcoal<br />

trade. ICRAF Working Paper no. 20. Nairobi, Kenya. World Agro<strong>for</strong>estry Centre<br />

Muok, B.O., Kimondo, J., and Omondi, W. (2007). Dryland Forestry Handbook<br />

<strong>for</strong> Kenya (2nd Edition). KEFRI.140p.<br />

Oduor, N. (2005). Calorific values of species as wood fuel and charcoal. A KEFRI<br />

Report.<br />

Republic of Kenya (2002). Study on Kenya’s Energy Demand, Supply and Policy<br />

Strategy <strong>for</strong> Households, Small Scale Industries and Service Establishments.<br />

Ministry of Energy, Nairobi, Kenya. Report submitted by KAMFOR Company<br />

Limited. September 2002. Pgs 133.<br />

Shanmughavel P. and Francis, K. (2001). Bioproductivity and nutrient<br />

cycling in bamboo and acacia plantation <strong>for</strong>ests. Bio-resource Technology,<br />

Volume 80 Issue1. October 2001, Pages 45-48, ISSN 0960-8524, 10.1016/<br />

S0960-8524(01)00060-8. http://www.sciencedirect.com/science/article/pii/<br />

S0960852401000608)<br />

State of Environment (2004). State of Environment Report. National<br />

Environment <strong>Management</strong> Authority, Kenya.www.nema.go.ke<br />

Theuri, K. (2002). Woodfuel Policy and Legislation in Kenya. A paper presented<br />

during the Regional Workshop on Woodfuel Policy and Legislation held at ICRAF,<br />

Nairobi, Kenya.<br />

20 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 21

Appendices<br />

Appendix 1:<br />

List of KEFRI Regional Centres and Sub Centres<br />

Regional Centres Sub-Centres Centre Director/<br />

Officer in Charge<br />

Telephone<br />

Contacts<br />

Muguga Mr E. Mwanza 0722-157414<br />

0724-259781/2<br />

0722-157414<br />

0722-386677<br />

Nyeri Dr. J. Lelon 0715-786844<br />

Karura Dr. J. Githiomi 020-2011628<br />

020-2011629<br />

0733-764726<br />

0722-496795<br />

Kitui Dr. N. Kamiri 044-22311<br />

044-22626<br />

0722-983238<br />

Kibwezi Mr. D. Muchiri 0721-700352<br />

Garissa Mr. B. Kigwa 0722-427231<br />

Bura Mr. Kimondo 0735-333809<br />

Londiani Dr. J Cheboiwo 052-64028<br />

0722-464469<br />

Marigat Mr. M. Welimo 0720-531655<br />

Turbo Mr. W. Atie 0722-480506<br />

Lodwar Mr. S. Ndungu 0720-143776<br />

Maseno Dr. R. Nyambati 0573-51164<br />

0713-687975<br />

Kakamega Mr. J. Maua 0721-601497<br />

Ramogi Mr. G. Wasonga 0729-779478<br />

Kuja River Mr. Ajuka 0726-561105<br />

Gede Mr. T. Mbuvi 0202386358<br />

0722-809951<br />

E-mail &<br />

Postal Address<br />

cdmuguga@kefri.org<br />

P.O. Box<br />

20412,00200,<br />

Nairobi<br />

cdkarura@kefri.org<br />

P.O. Box<br />

64636-00620,Mobil<br />

Plaza,<br />

Nairobi<br />

cdkitui@kefri.org<br />

P.O. Box 892, Kitui<br />

cdlondiani@kefri.org<br />

P.O. Box 382,<br />

Londiani<br />

cdgede@kefri.org<br />

P. 0. Box 1078-<br />

80200,<br />

Malindi<br />

Appendix 2:<br />

List of KEFRI Approved <strong>Tree</strong> Seed Stockists<br />

Company & Address Contact Person Telephone No.<br />

1 Kenya Farmers Association (KFA)<br />

P.O. Box 353, Kisii<br />

2 Alpha Agrovet<br />

P.O. Box 402, Othaya<br />

3 Maliki Agrovet<br />

P.O. Box 612, Njoro<br />

4 Menengai Agrovet<br />

P.O. Box 360, Nakuru<br />

5 Science Products<br />

P.O. Box 4946, Kisumu<br />

6 Greenland Agro<strong>for</strong>estry Nursery<br />

P.O. Box 1197, Thika<br />

7 Zayuni Farmcare<br />

P.O. Box 70, Shimba Hills<br />

8 Kinango Farm Care<br />

P.O. Box 70, Kinango<br />

9 Kiboko Forestry and Wildlife Reserves Glitd.<br />

P.O. Box 12 Machakos<br />

10 Suba Green Forest Initiative,<br />

P.O. Box 111-40100, Kisumu<br />

11 Snow Agrovet,<br />

P.O. Box 309, Kitui<br />

12 Adindi <strong>Tree</strong> Seeds & Organic Gardening Supplies<br />

P.O. Box 2383, Kisumu<br />

13 Sifuyo Youth Empowerment Centre,<br />

P.O. Box 31, Ukwala<br />

14 Kithimani Agrovet<br />

P.O. Box 1356, Kitui<br />

15 Atlas Pharmaceuticals<br />

P.O. Box 1507 Ukunda<br />

Mr. Yona Orao &<br />

Mr. Isaiah Otieno<br />

0721231238<br />

0725237654<br />

Mr. Justus Mukere 0721897380<br />

Mr. Harens Chazima 0712973398 or<br />

0723236804<br />

Mr. Zadock Munala 0724851302 or<br />

0512214087<br />

Mr. Moses M. Oduor 0721250752<br />

Mr. Charles Nyanjui 0728480907<br />

22 <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> <strong>Sustainable</strong> <strong>Tree</strong> <strong>Management</strong> <strong>for</strong> <strong>Charcoal</strong> <strong>Production</strong> 23<br />

Mr. Titus M.<br />

Mutonga<br />

Ms. Anyango<br />

Blandina Mukhwasi<br />

0721905236<br />

0727121398 or<br />

0736830594<br />

Major Charles Masai 722807907<br />

Mr. Julius Aduwo 0725636337<br />

Mr. Titus M. Katheke 0717168496<br />

0710817504<br />

Ms. Beatrice<br />

Odhiambo<br />

Mr. Stephen O.<br />

Awour<br />

0735535268<br />

0714808397<br />

0701008374<br />

Mr. Tommy M. Muli 0725548742<br />

0711227770<br />

Ms Judith Mumbua<br />

Kitusa<br />

0722480012

KEFRI’s mandate is to conduct research in <strong>for</strong>estry,<br />

collaborate with other research bodies within and outside<br />

Kenya carrying out similar research, liaise with other<br />

organisations and institutions of higher learning in training<br />

on matters of <strong>for</strong>estry research, and disseminate research<br />

findings. Its mission is to enhance the social and economic<br />

welfare of Kenyans through user-oriented research <strong>for</strong><br />

sustainable development of <strong>for</strong>ests and allied natural<br />

resources. www.kefri.org<br />

Practical Action Consulting is the dynamic consulting<br />

arm of international development and technology charity<br />

Practical Action. Sharing over 40 years of international<br />

expertise, Practical Action Consulting provides<br />

independent and professional consulting in the use of<br />

technology <strong>for</strong> poverty reduction to governments, NGOs,<br />

aid agencies and the private sector.<br />

www.practicalaction.org/consulting<br />

KFS is a public institution established under the Forests<br />

Act, 2005, with a mandate to contribute to the growth of<br />

the natural resource sector by enhancing development,<br />

conservation and management of all <strong>for</strong>est resources<br />

in Kenya. Among other activities, the Service promotes<br />

community involvement in <strong>for</strong>est conservation and<br />

management through Community Forest Associations,<br />

licensing of various activities and ventures, and<br />

conservancy management. www.kenya<strong>for</strong>estservice.org<br />

Through action research, the PISCES project is contributing<br />

to innovation and providing new policy-relevant knowledge<br />

on bioenergy – leading to better practices and widening<br />

energy access to the rural poor in East Africa and South<br />

Asia. It is the energy Research Programme Consortium<br />

funded by the UK’s DFID, whose members include ACTS<br />

(lead), Kenya; PAC-UK, Eastern Africa, and Sri Lanka; the<br />

University of Dar es Salaam, Tanzania; M.S. Swaminathan<br />

Research Foundation, India; and the University of<br />

Edinburgh, UK. For more in<strong>for</strong>mation contact project<br />

manager Bernard O. Muok at b.muok@acts.or.ke and visit<br />

www.pisces.or.ke