Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

STANDARD MACHINE ELEMENTS<strong>Catalogue</strong> <strong>14.0</strong>

®ContentsStandard Parts for Clamping and OperatingProduct range ............................................ 2Machine and Fixture ElementsProduct range ............................................ 4IntroductionThe Company ............................................ 6GANTER-Standard Machine Elements on DVD ................... 8GANTER-Standard Machine Elements in the Internet .............. 9Product FamilyStainless Steel .......................................... 10Table of contentsProduct overviews. ....................................... 12Alphabetical index ....................................... 901Numericalindex ........................................ 909AnnexTechnicalInformation, Tables. .............................. 881Otto <strong>Ganter</strong> GmbH & Co. KGNormteilefabrikTriberger Strasse 3D-78120 FurtwangenGermanyPhone +49 7723 6507-0Fax +49 7723 4659E-Mailinfo@ganter-griff.deInternet www.ganter-griff.com1

®Standard Parts for Clamping and Operating1.1HandlesKnobsPage 491.2Cabinet ªUº handlesTubular handlesPage 891.3Cranked handlesPage 1471.4HandwheelsPage 1611.5Adjustablehand leversPage 2011.6Clamping leversTension leversPage 2512

1.7Star knobs, Wing screwsKnurled screwsPage 2771.8Control knobsIndexing mechanismsPage 3371.11.9Position indicatorsPage 3751.21.31.41.51.61.71.81.93

®Machine and Fixture elements2.1Indexing plungersSpring plungers, Ball lock pinsPage 3912.2Screws, NutsWashersPage 4712.3Clamping bolts, Eccentrical camsShaft clamping unitsPage 5532.4Toggle clamps, Power clampsHook clampsPage 5732.5Levelling feetDoor locks, HingesPage 6812.6Oil level sight glassesPlugsPage 7374

2.7Universal joints2.8Fork joints, Ball jointsPage 761Tube clamp connectorsLinear actuatorsPage 7952.12.22.32.42.52.62.72.85

®GANTER-Standard Machine Elements

The CompanyEstablished in 1894, our medium-sized family-owned business has forover 100 years manufactured standard parts for every branch of industryat home and abroad.The Product RangeMany decades of experience have made us the leading supplier ofstandard operating and clamping parts and of fixture and machine elements.Our claim is backed by the scope and quality of our product offer.OTTO GANTER GmbH & Co. KGBerger Tools Ltd. UKELESA S.p.A - MONZA - (MILAN) - ITALYWith the publication of this catalogue, all previousissues become invalid. Technical detailsare subject to change without notice. The detailsgiven herein comply with state of the artengineering at the time of printing. We reservethe right to amend errors and to remove individualarticles from the product assortment.The products listed in this catalogue havebeen developed as standard products withthe aim of covering the widest possible spectrumof requirements. We cannot be heldliable and responsible for special applicationsinvolving extraordinary or unusual uses orrequirements concerning our products. Ourdesign department will be pleased to answerquestions on certain product properties suchas missing tolerance, dimensional details orstrength classes.All rights in the catalogue are held byOtto <strong>Ganter</strong> GmbH & Co. KG. Reprints, alsoin extracts, are not permitted.OTTO GANTER GmbH & Co. KGJune 2008The ServiceThe goods we hold in stock are customer driven:We normally deliver ex stock.Meeting specific customer requirements is an essentialelement ofour business policy.Rely on our experience, adaptability and modern production processes.The <strong>Catalogue</strong>Our GANTER catalogue is our showpiece display cabinet. Designedboth as a loose-leaf compendium of standard parts and a referencebook, its clear and user-friendly structure has set standards for manyyears.Besides the print version, the catalogue is also available on DVD andin the Internet, with CAD capable product drawings in 2D and 3D.Berger Tools Ltd.A wealth of UK engineering market knowledge, built up over 25 yearsmakes Berger Tools Ltd. a key single source supplier of all manufacturingconsumables. We are ISO 9001:2000 accredited and have acquireda reputation as a reliable and competitive supplier. As a ªfamily runºbusiness we understand the importance of excellent customer service.Our aim is to taylor our services to meet your procurement needs, andultimately be your single source for standard machine elements.ELESA Ò -StandardsFor 35 years ELESA products have accounted for an essentialpart ofthe GANTER product range.ELESA standards include an exclusive offer of operating and machineelements made of plastic ± unique in range, quality and design. 60years of experience in processing plastic materials have made ELESAthe market leader world-wide.It is plastic operating elements, in particular, which are available onthe market in very different quality levels.ELESA products are the result of a corporate philosophy which seesultimate quality standards as a manifestation of competence and commitmentto the customer.7

®GANTER-Standard Parts on DVDSelect, design and orderThe GANTER product range is also available on DVDas digital product catalogue.Working with the DVD is a quick, convenient and easy wayto access the whole product assortment.The interactive article selection provides all important productinformation items:Outline drawings with dimensional tables · Design · Photo ·Article number · RoHS conformity · Weight · Productdrawings in 2D (DXF) and 3D (IGES) · <strong>Catalogue</strong> pages inPDF format.After placing the DVD in the drive, the catalogue will start automatically.8

®GANTER-Standard Parts in the Internetwww.ganter-griff.com...amouse click awayThe GANTER product range is also available online atwww.ganter-griff.com ± always up to datewith the latest products.Various practicalselection procedures combined with the optionsof the Internet technology take you quickly to the productyou are looking for.Use the Quickfinder with its interactive selection to take youto the desired design or article number. Information on RoHSconformity is also given.The next steps are:Placing your selection in the shopping basket for enquiries ororders, downloading product drawings in 2D (DXF) and in allstandard 3D formats.CAD capable product drawings of the GANTER standardparts can also be downloaded free of charge via the CADportals www.partserver.com or www.traceparts.com9

®Product Family: Stainless Steel

The GANTER product range offers an extraordinary wealth ofstandard products made of Stainless Steel, meeting the rising demandfor reasonably priced Stainless Steel components.The use of Stainless Steel, rustfree material is prescribed by law inmany industries, particularly in the food and chemical industry andfor use in ªaggressiveº ambient conditions.Stainless Steel is often used in place of surface electro-plating. Italso avoids potentially hazardous and ecologically damaging processesand methods and uncontrollable dimensional changes causedby the materialplating.The chapter ªTechnicalInformationº on page 881 summarises themost important properties of the Stainless Steel grades used in theGANTER product range.11

®Handles, KnobsGN 798RevolvinghandlesTechnopolymer,Aluminium,SteelPage 50GN 798.1RevolvinghandlesTechnopolymer/Stainless SteelGN 598.5RetractablehandlesDuroplast/Stainless SteelPage 59GN 598.7Retractablesafety handlesDuroplast/SteelDIN 319Ball knobsSteel,Aluminium,Stainless SteelPage 67DIN 319Ball knobsDuroplastPress on typePage 51GN 798.3RetractablehandlesTechnopolymer/SteelPage 52GN 798.5RetractablehandlesTechnopolymer/Stainless SteelPage 53GN 598RevolvinghandlesDuroplast/SteelPage 60GN 599.5RevolvingcylindricalhandlesTechnopolymer/Stainless SteelPage 61DIN 98RevolvinghandlesSteel,Aluminium,TechnopolymerPage 62DIN 39Fixed handlesSteel,TechnopolymerPage 68I.622ELESA-Domedgear knobTechnopolymerPage 70GN 519CylindricalknobsDuroplastPage 72GN 519.1CylindricalknobsTechnopolymerPress on typePage 56GN 598.1RevolvinghandlesDuroplast/Stainless SteelPage 63GN 319.2Revolvingball knobsDuroplast/SteelPage 73GN 201Ellipticalshaped knobsDuroplastPage 57GN 598.3RetractablehandlesDuroplast/SteelPage 64DIN 319Ball knobsDuroplast,TechnopolymerPage 74GN 419Taper knobsDuroplastPage 58Page 66Page 7512Stainless Steel

1.1GN 310Gear leverhandlesDuroplast/SteelGN 676.1KnobsSteelPage 76GN 310Gear leverhandlesDuroplast/Stainless SteelPage 85GN 676.5KnobsStainless SteelPage 77GN 563.2T-HandlesAluminiumPage 85GN75Waist shapedknobsSteelPage 78L.652ELESA-T-HandlesTechnopolymerPage 86GN75Waist shapedknobsSteelPage 80L.652 pELESA-T-HandlesTechnopolymerThreaded shaftSteelPage 81EKKELESA-KnobsTechnopolymerPage 86GN76Mushroom typeknobsDuroplastPage 87GN76Mushroom typeknobsDuroplastPage 82Page 87EKK.pELESA-Knurled knobScrewsTechnopolymerPage 84Stainless Steel13

®Cabinet ªUº handlesTubular handlesGN 565CabinetªUº handlesAluminiumM.443 CHELESA-CabinetªUº handlesTechnopolymerGN 481Edge handlesAluminium/Zinc die castingPage 90GN 565.1CabinetªUº handlesAluminiumPage 100M.543ELESA-CabinetªUº handlesTechnopolymerPage 108GN 426CabinetªUº handlesAluminiumPage 92GN 565.2CabinetªUº handlesAluminiumPage 101GN 728CabinetªUº handlesAluminiumPage 110GN 426.1CabinetªUº handlesAluminiumPage 93GN 565.5CabinetªUº handlesStainless SteelPage 103GN 728.5CabinetªUº handlesStainless SteelPage 112GN 426.5CabinetªUº handlesStainless SteelPage 94GN 564CabinetªUº handlesfoam rubberPage 103GN 565.3CabinetªUº handlesAluminiumPage 113GN 334OvalhandlesAluminium/Zinc die castingPage 95EBPELESA-CabinetªUº handlesTechnopolymerPage 105GN 668Flat CabinetªUº handlesAluminiumPage 114GN 669System handlesAluminium/TechnopolymerPage 96M.843ELESA-CabinetªUº handlesTechnopolymerPage 106GN 559CabinetªUº handlesAluminiumPage 116GN 333Tubular handlesAluminium/Zinc die castingPage 98Page 107Page 11814Stainless Steel

1.2GN 333.1Tubular handlesAluminium/Zinc die castingPage 120GN 333.5TubularhandlesStainless SteelGN 424ArchhandlesStainless SteelPage 132GN 427CabinetªUº handlesAluminiumGN 425.4Folding handlewithrecessed traySteel/Zinc die castingPage 140GN 425.2FoldinghandlesSteelPage 122GN 666Tubular handlesAluminium/TechnopolymerPage 133GN 425CabinetªUº handlesSteelPage 142GN 425.2FoldinghandlesStainless SteelPage 124GN 666.1Tubular handlesAluminium/TechnopolymerPage 134GN 425.6CabinetªUº handlesAluminiumPage 142GN 425.1CabinetªUº handlesSteelPage 126GN 667Tubular handlesAluminium/TechnopolymerPage 134GN 425CabinetªUº handlesStainless SteelPage 144GN 225CabinetªUº handlesCast ironPage 127GN 565.4Arch handlesAluminiumPage 136GN 425.3CabinetªUº handlesStainless SteelPage 145Page 128GN 665Arch handlesAluminiumPage 137GN 730Ledge handlesAluminiumPage 130Stainless SteelPage 13815

®Cranked handles1.3GN 471Cranked handlesAluminiumGN 112.1ControlhandlesZinc die castingPage 148GN 471.1Cranked handlesZinc die castingPage 156GN10Tri-ball handlesSteelPage 148GN 471.3Cranked handleswithretractablehandpieceAluminiumPage 150GN 472.3Cranked handleswithretractablehandpieceAluminiumPage 151DIN 468Cranked handlesMalleableCast ironPage 158GN 558Indexingcranked handlesCast ironPage 159Page 152DIN 469Cranked handlesMalleableCast ironPage 153GN 369Cranked handlesSteelPage 15416Stainless Steel

®Handwheels1.4DIN 950HandwheelsCast iron,AluminiumVDSELESA-DischandwheelsTechnopolymerGN 226.1Cover discsfor GN 226Page 162DIN 3670DischandwheelsAluminiumPage 163GN 321DischandwheelsAluminiumPage 164GN 323DischandwheelsAluminium,Plastic coatedPage 174VD.FPELESA-DischandwheelsDuroplastPage 176GN 555HandwheelsDuroplastPage 178GN 736ControlknobsAluminium,black anodizedPage 185VDS+IRELESA-Handwheelswith retractablehandleTechnopolymerPage 186VRTP+IRELESA-Handwheelswith retractablehandleTechnopolymerPage 187GN 322.3Handwheelswith retractablehandleAluminiumPage 166GN 322HandwheelsAluminiumPage 180GN 736.1ControlknobsAluminium,black anodizedPage 188GN 322.7Handwheelswith safetyhandleAluminiumPage 168GN 324HandwheelsAluminium,Plastic coatedPage 181VL.640 FPELESA-HandwheelsTechnopolymerPage 189GN 321.4GN 321.5SafetyhandwheelsAluminiumPage 170VRTPELESA-HandwheelsTechnopolymerPage 182GN 226KnurledhandwheelsTechnopolymerPage 190GN 322.4GN 322.5SafetyhandwheelsAluminiumPage 172Stainless SteelPage 184Page 19017

®Handwheels1.4GN 323.4GN 323.5SafetyhandwheelsAluminiumPage 190GN 000.4CouplingattachmentsPage 192GN 000.5CouplingattachmentsPage 193GN 321.6SafetyhandwheelsAluminiumPage 194GN 227.2HandwheelsStainless SteelPage 196GN 227.1HandwheelsPressed steelPage 198GN 227HandwheelsPressed steelPage 19918Stainless Steel

®Adjustable hand levers1.5GN 300Adjustablehand leversZinc die castingPage 202GN 300Adjustablehand leversZinc die castingPage 205GN 300.1Adjustablehand leversinternalpartsStainless SteelGN 302Adjustablehand leversZinc die castingPage 213GN 300.4Adjustablehand leverswith increasedclamping forcePage 214GN 300.4Adjustablehand leverswith increasedclamping forceERZ.SSTELESA-Adjustablehand leversTechnopolymerinternalpartsStainless SteelPage 226ERZ.SST-pELESA-Adjustablehand leversTechnopolymerinternalpartsStainless SteelPage 227ERXELESA-Adjustablehand leversTechnopolymerPage 206GN 300.1Adjustablehand leversinternalpartsStainless SteelPage 217GN 101Adjustablehand leversZinc die castingPage 228ERX.pELESA-Adjustablehand leversTechnopolymerPage 207GN 300.5Adjustablehand leversStainless SteelPage 218GN 101Adjustablehand leversZinc die castingPage 231GN 212.3Adjustabletension leversSteelPage 208GN 300.5Adjustablehand leversStainless SteelPage 221ERZELESA-Adjustablehand leversTechnopolymerPage 232GN 212.3Adjustabletension leversSteelPage 209GN 302Adjustablehand leversZinc die castingPage 222ERZ.pELESA-Adjustablehand leversTechnopolymerPage 235GN 212.5Adjustabletension leversStainless SteelPage 212Stainless SteelPage 225Page 23619

®Adjustable hand levers1.5GN 212.5Adjustabletension leversStainless SteelGN 6337.3Adjustableclamping leversSteelPage 237GN 312Safetytension leversSteelPage 246GN 6337.3Adjustableclamping leversSteelPage 238GN 312Safetytension leversSteelPage 247GN 316RatchetspannersSteelPage 239GN 125Flat adjustabletension leversSteelPage 248Page 240GN 125Flat adjustabletension leversSteelPage 243GN 99.2Adjustableclamping leversSteelPage 244GN 99.2Adjustableclamping leversSteelPage 24520Stainless Steel

®DIN 99Clamping leversSteelClamping leversTension leversGN 206Clamp nutsMalleableCast ironDIN 6306Tommy screwsSteel1.6Page 252DIN 99ClampingleversStainless SteelPage 260GN 206.1Clamp nutsMalleableCast ironPage 267GN 212Tension leversSteelPage 253DIN 6337Ball leversSteelPage 261ERFELESA-Clamping leversTechnopolymerPage 268GN 212TensionleversStainless SteelPage 254GN 99.5Clamp nutsSteelPage 262ERF.pELESA-Clamping leversTechnopolymerPage 269GN 750ControlleversSteelPage 256GN 99.6Clamp nutsStainless SteelPage 262DIN 6305Tommy nutsSteelPage 270GN 150Split hubsSintered steelPage 257GN 99.7Clamp nutswithdouble leverSteelPage 264DIN 6307Tommy nutsSteelPage 272GN 223ControlleversSteelPage 258GN 99.8Clamp nutswithdouble leverStainless SteelPage 265DIN 6304Tommy screwsSteelPage 274GN 213Turret leversSteelPage 259Stainless SteelPage 266Page 27521

®Star knobsWing screws, Wing nutsDIN 6336Star knobsCast iron,AluminiumPage 278DIN 6336Star knobsPlastic/SteelPage 279GN 6336.1GN 6336.2Star knobsPlastic/SteelVCTELESA-Star knobsTechnopolymerPage 286VCT.pELESA-Star knobs withthreaded boltTechnopolymerPage 289GN 5336Star knobsAluminiumGN 5337.3Safety-Star knobs withfemale threadedinternalpartsSteel/Stainless SteelPage 296GN 5337.3Safety-Star knobs withmale threadedinternalpartsSteel/Stainless SteelPage 296DIN 6335Star knobsCast iron,AluminiumPage 280GN 6336.1GN 6336.2Star knobsPlastic/Stainless SteelPage 290GN 5334Star knobsStainless SteelPage 298DIN 6335Star knobsPlastic/SteelPage 281GN 6336.4Star knobsPlastic/Cast ironPage 292GN 5334Star knobswiththreaded boltStainless SteelPage 299GN 6335.1GN 6335.2Star knobsPlastic/SteelPage 282GN 6336.5Star knobsTechnopolymer/Stainless SteelPage 293GN 5335Star knobsStainless SteelPage 300GN 6335.2Star knobsTechnopolymer/Stainless SteelPage 283GN 6336.3Quick releasestar knobsTechnopolymer/SteelPage 294GN 5339.5TriangularknobsStainless SteelPage 301GN 6335.4Star knobsPlastic,Cast ironPage 284Page 295Page 30222Stainless Steel

1.7GN 6335.5Star knobsTechnopolymer/Stainless SteelGN 734Wing nutsStainless SteelGN 421Knurledthumb screwsTechnopolymer/SteelPage 303GN 6335.9Star knobswithincreasedclamping forcePage 312GN 432Wing nutsStainless SteelPage 322GN 421Knurledthumb screwsTechnopolymer/Stainless SteelPage 304VB.639ELESA-Tristar knobsTechnopolymerPage 314GN 431Wing screwsStainless SteelPage 323DIN 6303Knurled nutsSteelPage 305VB.639 pELESA-Tristar knobsTechnopolymerPage 315MBTELESA-Knurled knobsTechnopolymerPage 324DIN 6303Knurled nutsStainless SteelPage 307CT.476ELESA-Wing nutsTechnopolymerPage 308CT.476 pELESA-Wing screwsTechnopolymerPage 316MBT.pELESA-Knurled knobswiththreaded boltTechnopolymerPage 319GN 420Knurled nutsTechnopolymer/SteelPage 325GN 6303.1Quick releaseknurled nutsSteelPage 326EKKELESA-KnobTechnopolymerPage 310CT.476 S-pELESA-Wing screwsTechnopolymer/Stainless SteelPage 320GN 420Knurled nutsTechnopolymer/Stainless SteelPage 82EKK.pELESA-Knurled knobScrewsTechnopolymerPage 311Stainless SteelPage 321Page 8423

®GN 676.1KnobsSteelStar knobsWing screws, Wing nutsDIN 653Flat knurledthumb screwsStainless Steel1.7Page 85GN 676.5KnobsStainless SteelPage 333DIN 467Flatknurled nutsSteelPage 85DIN 464Knurledthumb screwsSteelPage 334DIN 467Flatknurled nutsStainless SteelPage 328DIN 464Knurledthumb screwsStainless SteelPage 335Page 329DIN 466Knurled nutsSteelPage 330DIN 466Knurled nutsStainless SteelSeite 331DIN 653Flat knurledthumb screwsSteelPage 33224Stainless Steel

®Control knobsAdjustable slide units1.8GN 164Scale ringsSteelGN 727Controlknobswith adjustablespindleGN 900Adjustableslide unitsAluminiumPage 339GN 726ControlknobsAluminium,blackanodizedPage 348GN 200IndexingmechanismsSteelPage 364GN 900.1Fastening unitsAluminiumPage 340GN 726.1ControlknobsAluminium,blackanodizedPage 342GN 726.2ControlknobsAluminium,blackanodizedPage 350GN 200Indexingmechanismswithtension leversSteelPage 350GN 200IndexingmechanismsStainless SteelPage 366GN 900.2Connectingsets X-YAluminiumPage 367GN 900.3Connectingsets X-ZAluminiumPage 343GN 723.4ControlknobsAluminium,naturalcolouranodizedPage 352GN 700Adjustable knobwith steplesspositioningSteelPage 368GN 900.4Mounting platesAluminiumPage 344GN 723.3Referenceflangesfor controlknobsGN 723.4Page 354GN 215Indexing leversSteelPage 370GN 900.5Rotary platesAluminiumPage 346GN 729ControlknobsAluminium,blackanodizedPage 356GN711RulersPlastic,Stainless SteelPage 371GN 900.6RotarytablesStainless SteelPage 347Stainless SteelPage 358Page 37225

®Position indicators1.9GAELESA-PositionindicatorspendulumsystemPage 379GN 323.8Dischandwheelsfor positionindicators GAPage 380DD52RELESA-PositionindicatorsdigitalindicationPage 384BS52ELESA-Spacer platefor DD52RMD51ELESA-Hand knobfor DD51Page 388RB51RB52ELESA-Adapter bushesfor DD52Rand DD51Page 389Page 385GN 952.5Clamping platesfor DD51 andDD52RPage 386DD51ELESA-PositionindicatorsdigitalindicationPage 387BS51ELESA-Spacer platefor DD51Page 38826Stainless Steel

®GN 617IndexingplungersIndexing elementsSpring plungersGN 817IndexingplungersGN 607.1Indexingplungerswith rest positionStainless Steel2.1Page 398GN 617IndexingplungersStainless SteelPage 399GN 613Indexingplungerswithout headPage 400GN 613Indexingplungerswithout headStainless SteelPage 405GN 817IndexingplungersStainless SteelPage 405GN 717IndexingplungersPage 406GN 717IndexingplungersStainless SteelPage 409GN 607.2Indexingplungers forinstallation inthin walledequipmentPage 410GN 607.3Indexing plungerswith rest positionfor installationin thin walledequipmentPage 411GN 608IndexingplungersPage 400GN 618Indexingplungerswithout threadPage 406GN 607IndexingplungersPage 412GN 608.1Indexingplungerswith restpositionPage 401GN 617.1Indexingplungerswith restpositionPage 408GN 607IndexingplungersSteel,Stainless SteelPage 413GN 817.3IndexingplungersPage 402GN 617.1Indexingplungerswith restpositionStainless SteelPage 403Stainless SteelPage 408GN 607.1Indexingplungers withrest positionPage 409Page 414GN 822Mini indexingplungerswith/withoutrest positionPage 41627

®Indexing elementsSpring plungersGN 609Distancebushingsfor indexingplungersGN 612Cam actionindexingplungersGN 6336.7Hand knobswithindexingplungerPage 418GN 609.5Distancebushingsfor indexingplungersStainless SteelPage 418GN 417Indexingplungerswithoutrest positionPage 420GN 417Indexingplungerswithrest positionPage 421GN 412.1Mounting blocksfor indexingplungers and camaction indexingplungersZinc die castingPage 422GN 412.2Positioningbushingsfor indexingplungersSteelPage 423GN 612.1Mounting blocksfor indexingplungers andcam actionindexingplungers, SteelPage 426Page 427GN 612Cam actionindexingplungersStainless SteelPage 427GN 612.2Cam actionindexing plungerswith flangefor surfacemountingPage 428GN 612.3Cam actionindexingplungers forweldmountingPage 429GN 712Cam actionindexingplungersplunger innormalpositionprotrudedPage 430GN 712.1Cam actionindexingplungersplunger innormalpositionretractedPage 432GN 513SpringelementsPage 434Page 435GN 249Ball buttonsfor springplungersPage 436GN 250Indent blocksfor springplungersPage 437GN 614SpringplungersTechnopolymerStainless SteelPage 438GN 614.1Holder forspringplungersGN 614Page 439GN 615Springplungerswith slotPage 440GN 615Springplungerswith slotStainless SteelPage 44028Stainless Steel

2.1GN 615.3Springplungerswith hexagonsocketSteel,Stainless SteelPage 441GN 615.3Springplungerswiththread lockingSteel,Stainless SteelPage 441GN 615.2SpringplungersTechnopolymerGN 614.3Springplungersplain typeStainless SteelPage 446GN 614.2Springplungersdouble endedPage 447GN 815Springplungerswith headSteelGN 715Side thrustpinspress fitPage 452GN 714Side thrustpinswithoutthrust pinPage 453GN 713Side thrustpinsthreadedbodyPage 442GN 615.1Springplungerswith boltPage 443GN 615.1Springplungerswith boltStainless SteelPage 448GN 815Springplungerswith headStainless SteelPage 448GN 610Spring loadedshellsPage 454GN 715.2Eccentricbushesfor side thrustpinsGN 715Page 457GN 716Side thrustpinsPage 443GN 616Springplungerswith boltPage 449GN611Springplungerslong strokePage 458GN 113Balllock pinsself lockingStainless SteelPage 444GN 616Springplungerswith boltStainless SteelPage 450GN 615.7Springplungerswithlimit switchPage 462GN 113.2Balllock pinsself lockingStainless SteelPage 445Stainless SteelPage 451Page 46329

®Indexing elementsBall lock pins2.1GN 113.3Ball lockpinsself lockingStainless SteelPage 464GN 124Pins withaxiallockStainless SteelPage 465GN 114.1Pins withaxiallockPage 466GN 114.5Pins withaxiallockStainless SteelPage 466GN 114Pins withaxiallockPage 467GN 113.1Ball lockpinswith clampinglengthcompensationPage 468GN 111Ball chainsPage 46930Stainless Steel

®Screws, NutsWashers2.2GN 913.3Grub screwswith brass orplastic padGN 709.3Clamping padswith heightadjustmentGN 346Ball jointthrust padsPage 472GN 913.5Grub screwswith brass orplastic padStainless SteelPage 480GN 709.1Clamping padswithmale threadPage 489GN 347Hexagon nutswith ballsocketPage 473GN 913.2Grub screwswith hardenednosePage 482GN 709.2Clamping padswithfemale threadPage 490GN 806Protective capsPage 474GN 605Ball pointscrewsPage 483DIN 6332Grub screwswiththrust pointPage 491GN 251Setting boltsPage 476GN 605Ball pointscrewsStainless SteelPage 484DIN 6311Thrust padsPage 492GN 251.2Setting boltswith limitswitchPage 477GN 606Ball pointscrewsPage 486GN 6311.1Thrust padsSteel/TechnopolymerPage 493GN 551.1Grub screwsthreaded rodsPage 478GN 606Ball pointscrewsStainless SteelPage 487GN 638Ball jointedlevelling feetSteel,Stainless SteelPage 494GN 252Blanking plugsPage 479Stainless SteelPage 488Page 49531

®Screws, NutsWashersDIN 444Swing boltsPage 496DIN 444Swing boltsStainless SteelDIN 6379Studsfor T-NutsPage 504DIN 787T-Slot boltsGN 506.1T-Nutsfor linkingaluminiumextrusionsSteel,Stainless SteelPage 511DIN 6330Hexagon nutswith sphericalseatingPage 496GN 1524Swing boltswith fullythreaded boltPage 497GN 444.2Swing nutsPage 505GN 508.2T-Nutsslip proofPage 506GN 508.1RhombusT-NutsPage 512DIN 6330Hexagonnutswith sphericalseatingStainless SteelPage 512DIN 6331Collar nutsPage 498GN 732Cylinder headshoulder boltsPage 507GN 505T-Nutsfor aluminiumextrusionsPage 513GN 350LevellingsetsSteel,Stainless SteelPage 500DIN 508T-NutsPage 508GN 507T-Nutsfor linkingaluminiumextrusionsPage 514GN 350.1LevellingsetsSteel,Stainless SteelPage 502DIN 508T-NutsStainless SteelPage 509GN 506T-Nutsfor linkingaluminiumextrusionsPage 516GN 350.2LevellingsetsSteel,Stainless SteelPage 503Page 510Page 51732Stainless Steel

2.2GN 350.3SphericallevellingwashersSteel,Stainless SteelPage 518DIN 6319SphericalwashersGN 184CountersunkwashersPage 527GN 184.5CountersunkwashersStainless SteelGN 705Set collarsStainless SteelPage 532GN 706Semi-splitset collarsPage 520DIN 6319SphericalwashersStainless SteelPage 527GN 185BezeldiscsStainless SteelPage 534GN 706Semi-splitset collarsStainless SteelPage 521GN 6339Heavy dutywashersPage 528GN 338Discswith cover capPage 534GN 707Splitset collarsPage 522GN 187Serratedlocking platesPage 529GN 183C-WashersPage 535GN 707Splitset collarsStainless SteelPage 524GN 187.1Guide potsPage 530DIN 6371CaptiveC-WashersPage 535DIN 6340WashersPage 526GN 187.2Thrust springsPage 531GN 705Set collarsPage 536DIN 1804SlottedlocknutsPage 526Stainless SteelPage 532Page 53733

®DIN 580Liftingeye boltsmaleScrews, NutsWashersGN 509.3SpringringsStainless Steel2.2Page 538DIN 580Liftingeye boltsmaleStainless SteelPage 545DIN 6885KeysSteelPage 538DIN 582Liftingeye boltsfemalePage 546DIN 6885KeysStainless SteelPage 539DIN 582Liftingeye boltsfemaleStainless SteelPage 547GN 230ShallowT-NutsPage 539GN 581Liftingeye bolts(rotating)Page 548GN 770Guide bushesPage 540GN 509Balltransfer unitsSteel,Stainless SteelPage 550GN 771Guide pinsPage 542GN 509.1Balltransfer unitsSteel,Stainless SteelPage 551Page 54434Stainless Steel

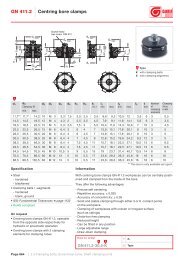

®Clamping boltsEccentrical cams2.3GN 927Clamping leverswitheccentricalcamGN 918.7ClampingboltsStainless SteelGN 928Shaftclampingunits'trueround'Page 554GN 919Hubs witheccentricalcamPage 561GN 917Double camleversPage 570Page 556GN 918EccentricalcamsPage 562GN 917.1Double camleversStainless SteelPage 558GN 918.5EccentricalcamsStainless SteelPage 562GN 921WedgeclampsPage 558GN 918.1ClampingboltsPage 564GN 921.1Locking platfor GN 921Page 560GN 918.6ClampingboltsStainless SteelPage 564GN 920WedgeclampsPage 560GN 918.2ClampingboltsPage 566GN411Centring boreclampsPage 561Page 568Stainless Steel35

®Toggle clampsPower clamps, Hook clampsGN 810VerticalclampsGN 910.3Knee levermodulesfor weldingGN 812VerticalclampsPage 576GN 810VerticalclampsStainless SteelPage 590GN 910.5Handleaccessories forKnee levermodulesPage 594GN 820HorizontalclampsPage 578GN 810.1VerticalclampsPage 580GN 810.1VerticalclampsStainless SteelPage 582GN 910Verticalclampsheavy duty typeªLonglifeºPage 591GN 910.6Lever armHandleaccessories forKnee levermodulesPage 591GN 910.7Clamping armelongationaccessories forKnee levermodulesPage 591GN 910.8Bushingaccessories forKnee levermodulesPage 596GN 820HorizontalclampsStainless SteelPage 598GN 820.1HorizontalclampsPage 600GN 820.1HorizontalclampsStainless SteelPage 584GN 910.1Verticalclampsheavy duty typeªLonglifeºPage 591GN 910.9Base plateaccessories forKnee levermodulesPage 602GN 840PlungerclampsPage 586GN 910.2Knee levermodulesto screw-onPage 591GN 813VerticalclampsPage 604GN 844PlungerclampsPage 588Page 592Page 60636Stainless Steel

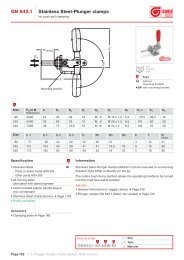

2.4GN 841Plunger clampsGN 851.1Latch clampsGN 860PneumaticallyoperatedclampsPage 608GN 842Plunger clampsPage 622GN 851.1LatchclampsStainless SteelPage 632GN 861PneumaticallyoperatedclampsPage 610GN 843.1Plunger clampsPage 624GN 851.2Latch clampsPage 634GN 862PneumaticallyoperatedclampsPage 612GN 843.1PlungerclampsStainless SteelPage 626GN 852Latch clampsheavy duty typewith fixing holesSteelPage 636GN 863PneumaticallyoperatedclampsPage 614GN 850Hook clampsPage 628GN 852Latch clampsheavy duty typefor weldingSteelPage 638GN 890PneumaticallyoperatedclampsPage 616GN 851Latch clampsPage 618GN 851LatchclampsStainless SteelPage 620Stainless SteelPage 628GN 852Latchclampsheavy duty typewith fixing holesStainless SteelPage 630GN 852Latchclampsheavy duty typefor weldingStainless SteelPage 630Page 640GN 807ClampingboltsSteel,Stainless SteelPage 642GN 708ClampingboltsSteel,Stainless SteelPage 64337

®Toggle clampsPower clamps, Hook clampsGN 802Clamping boltsSteelGN 867Holders forclamping boltsGN 871Levelling shimsPage 644GN 903ClampingboltsSteel,Stainless SteelPage 656GN 867.1Static holdersPage 663GN 873Collar clampsPage 645GN 804Clamping boltsSteelPage 657GN 868Holders forclamping jawsPage 664GN 870Guide bushesPage 646GN 896.1GN 896.2GN 896.3Proximityswitcheswith mountingbracketPage 647GN 864Power clampsPage 658GN 868.1Holders forclamping jawsPage 659GN 869.1Static holdersPage 666GN 893.1GN 893.2GN 893.3Proximityswitcheswith holderPage 667GN 821HookclampsSteel,Stainless SteelPage 650GN 865Power clampsPage 660GN 869.2Holders forclamping jawsPage 668GN 831HookclampsSteel,Stainless SteelPage 652GN 866Power clampsPage 661GN 872Clamping jawsblankPage 670GN 831.1HookclampsSteel,Stainless SteelPage 654Page 662Page 67238Stainless Steel

2.4GN 832HookclampsSteel,Stainless SteelPage 673GN 832.1HookclampsSteel,Stainless SteelPage 674GN 832.2HookclampsSteel,Stainless SteelPage 676GN 832.3HookclampsSteel,Stainless SteelPage 677GN 832.4HookclampsSteel,Stainless SteelPage 678GN 833HookclampsSteel,Stainless SteelPage 679Stainless Steel39

®Levelling feetDoor locks, HingesGN 343.1Levelling feetSteelGN 343.8LevellingfeetTechnopolymer/Stainless SteelGN 340Levelling feetSteelPage 682GN 343.2Levelling feetSteelPage 687GN 342.1Levelling feetvibrationabsorbingPage 698GN 340.5LevellingfeetStainless SteelPage 682GN 343.3Levelling feetTechnopolymer/SteelPage 688GN 342.2Levelling feetvibrationabsorbingPage 698GN 341LevellingfeetStainless SteelPage 685GN 343.4Levelling feetTechnopolymer/SteelPage 685GN 343.5LevellingfeetStainless SteelPage 688GN 344.1ELESA-Levelling feetTechnopolymer/SteelPage 690GN 344.6ELESA-Levelling feetTechnopolymer/Stainless SteelPage 699GN 341.1Levellingfeetfor use inhygieneenvironmentStainless SteelPage 700GN 440Levelling feetSteelPage 686GN 343.6LevellingfeetStainless SteelPage 692GN 345.1ELESA-Levelling feetTechnopolymer/SteelPage 702GN 440.5LevellingfeetStainless SteelPage 686GN 343.7LevellingfeetTechnopolymer/Stainless SteelPage 694GN 345.6ELESA-Levelling feetTechnopolymer/Stainless SteelPage 702GN 339Levelling feetSteelPage 687Page 696Page 70440Stainless Steel

2.5GN 349Threadedmounting platesforlevelling feetSteelPage 705GN 348.1Insert bushesfor profiledsquare tubesTechnopolymerGN 115Locksnot lockablePage 716GN 115LockslockableGN 237Hinges for screwmountingAluminiumPage 727GN 237Hingesfor screwmountingStainless SteelPage 706GN 992Threadedtube insertsfor tubingsGN 990AluminiumPage 708GN 218Cam latchesPage 718GN 115.1Mini-LocksPage 720GN 115Door locksStainless SteelPage 727CFMELESA-HingesTechnopolymerPage 728GN 238Hinges for screwmounting,adjustablePage 709GN 117Door locksPage 722GN 123Sheet metalpunchesfor mountingof locksPage 730GN 127Hinges for screwmounting,adjustablePage 710GN 119Door locksPage 723GN 161HingesZinc die castingPage 732GN 129Hinges for screwmountingPage 712GN 116Door locksPage 724GN 237Hinges for screwmountingZinc die castingPage 734GN 128Hinges for weldmountingPage 714Stainless SteelPage 727Page 73541

®GN 743GN 743.1Oillevelsight glassesAluminium/naturalglassPage 738GN 744Prismaticoillevelsight glassesAluminium/TechnopolymerPage 739GN 743.2GN 743.3Oillevelsight glassesBrass/naturalglassPage 740GN 743.5Oillevelsight glassesStainless Steel/naturalglassOil level sight glassesPlugsGN 541.1ELESA-Oillevelsight glassesTechnopolymerPage 746HCZELESA-OillevelindicatorsTechnopolymerPage 748GN 749Threaded plugsSteelPage 750GN 741GN 742Threaded plugsAluminiumSFPELESA-Breather capsTechnopolymerPage 7582.6Page 742GN 743.6ATEX-Levelsight glassesAluminium/naturalglassPage 752GN 738GN 738.1Magnetic plugsAluminiumPage 743GN 743.7GN 743.8Oillevelsight glasseswith conicalthreadBrassPage 744GN 537Oillevelsight glassesAluminium/PerspexPage 753TNELESA-Threaded plugsTechnopolymerPage 754GN 543.1Fixing nutsfor oillevelsight glassesPage 745Page 75642Stainless Steel

®Universal joints, Fork joints2.7DIN 808Universaljointswithfriction bearingGN 648.1Ball jointswithfemale threadGN 782Ball jointsPage 766GN 808.2Universaljointshafts withfriction bearingPage 776GN 648.2Ball jointswiththreaded boltPage 784DIN 71802Angledball jointsPage 767DIN 808Universaljoints withfriction bearingStainless SteelPage 777GN 648.5Ball jointswithfemale threadStainless SteelPage 786DIN 71802Angledball jointsStainless SteelPage 768DIN 808Universaljointswithneedle bearingPage 778GN 648.6Ball jointswiththreaded boltStainless SteelPage 787GN 710Dust capsfor angledball jointsDIN 71802Page 770GN 808.3Universaljointshafts withneedle bearingPage 779GN 751Fork jointsFork headsDIN 71752Page 789GN 240Quick-fitcouplingsPage 771GN 908Universaljointsfor ordinaryapplicationsPage 780GN 751Fork jointsFork headsDIN 71752Stainless SteelPage 790GN 240.1Quick-fitcouplingsPage 772GN 808.1Gaiters foruniversaljointsPage 781GN 752Joint piecesSteel,Stainless SteelPage 792GN 240.2Quick-fitcouplingsPage 773Stainless SteelPage 783Page 79343

®Tube clamp connectorsLinear actuatorsGN 131Two-wayconnectorclampsAluminium,Stainless SteelPage 798GN 132Two-wayconnectorclampsAluminiumPage 800GN 133Two-wayconnectorclampsAluminiumGN 147FlangedconnectorclampsAluminiumPage 810GN 162Base plateconnectorclampsAluminium,Stainless SteelPage 811GN 163Base plateconnectorclampsAluminiumGN 191T-AngleconnectorclampsAluminium,Stainless SteelPage 819GN 192T-AngleconnectorclampsAluminiumPage 820GN 193T-AngleconnectorclampsAluminiumPage 801GN 134Two-wayconnectorclampsAluminiumPage 812GN 165Base plateconnectorclampsAluminiumPage 822GN 194T-AngleconnectorclampsAluminiumPage 802GN 141Flangedtwo-wayconnectorclampsAluminiumPage 804GN 145FlangedconnectorclampsAluminium,Stainless SteelPage 806GN 146FlangedconnectorclampsAluminiumPage 807Page 814GN 166Off-setbase plateconnectorclampsAluminiumPage 816GN 167Wide base plateconnectorclampsAluminiumPage 817GN 171Flangedbase plateconnectorclampsAluminiumPage 818Page 824GN 195T-AngleconnectorclampsAluminiumPage 826GN 231TubesupportsAluminiumPage 828GN 241TubeconnectorsAluminiumPage 82944Stainless Steel

2.8GN 271SwivelclampconnectorbasesAluminiumGN 278SwivelclampconnectorsAluminiumGN 287SwivelclampconnectorjointsAluminiumPage 832GN 272SwivelclampconnectorbasesAluminiumPage 839GN 281SwivelclampconnectorjointsAluminiumPage 848GN 288SwivelclampconnectorjointsAluminiumPage 833GN 273SwivelclampconnectorsAluminiumPage 834GN 274SwivelclampconnectorsAluminiumPage 842GN 282SwivelclampconnectorjointsAluminiumPage 843GN 283SwivelclampconnectorjointsAluminiumPage 849GN 990ConstructiontubingsSteel,Aluminium,Stainless SteelPage 850GN 991Tube end plugsPage 835GN 275SwivelclampconnectorsAluminiumPage 844GN 284SwivelclampconnectorjointsAluminiumPage 852GN 911.3Adjustablehandle setsSteelPage 836GN 276SwivelclampconnectorsAluminiumPage 845GN 285SwivelclampconnectorjointsAluminiumPage 853GN 911.4Adjustablehandle setsStainless SteelPage 837GN 277SwivelclampconnectorsAluminiumPage 846GN 286SwivelclampconnectorjointsAluminiumPage 853GN 911.1Cap headscrew setsSteelPage 838Stainless SteelPage 847Page 85445

®GN 911.2Cap headscrew setsStainless SteelTube clamp connectorsLinear actuatorsGN 132.1GN 132.2Linear actuatorconnectorsAluminiumGN 273.1Swivelclamplinear actuatorconnectorsAluminium2.8Page 854GN 911.5Hexagon headscrew setsSteelPage 855GN 911.6Hexagonheadscrew setsStainless SteelPage 865GN 145.1Flangedlinear actuatorconnectorsAluminium,Stainless SteelPage 866GN 146.1Flangedlinear actuatorconnectorsAluminiumPage 872GN 274.1Swivelclamplinear actuatorconnectorsAluminiumPage 873GN 736.18Handwheelforlinear actuatorÆ 18Page 855GN 291LinearactuatorsSteel,Stainless SteelPage 860GN 292LinearactuatorsSteel,Stainless SteelPage 867GN 162.1Base platelinear actuatorconnectorsAluminium,Stainless SteelPage 868GN 163.1Base platelinear actuatorconnectorsAluminiumPage 874GN 323.30GN 323.40Handwheelforlinear actuatorÆ 30 and Æ 40Page 874GN 324.40GN 324.50Handwheelforlinear actuatorÆ 40 and Æ 50Page 862GN 293LinearactuatorsSteel,Stainless SteelPage 863GN 131.1GN 131.2Linear actuatorconnectorsAluminium,Stainless SteelPage 864Page 869GN 191.1T-Anglelinear actuatorconnectorsAluminium,Stainless SteelPage 870GN 192.1T-Anglelinear actuatorconnectorsAluminiumPage 871Page 874/875GN 295Installation kitsfor positionindicators usedon linearactuatorsPage 877GN 299Longitudinalscales forlinear actuatorsPage 87846Stainless Steel

®Stainless Steel47

HandlesKnobs1.1

®Revolving handles GN 798d1 d2 d3 d4 l1 l2 l3 l416 M 6 ± 10 13 41,5 12 2,5 1518 M 6 M 8 10 14,5 56 13 2,5 1922 M 8 M 10 14 18,5 59 14 2,5 2124 M 8 M 10 14 18,5 74 16 2,5 2725 M 10 ± 16 20 84 16 2,5 30SpecificationPlastic KTTechnopolymer (Polyamide PA)temperature resistantup to 90° Cblack, matt finishAluminium ALturned and polishedSpindle steelzinc plated,blue passivatedPlasticcharacteristics Page 897InformationTypicalin design are our revolving handles GN 798(photo page 54) with their stepped shape consistingof two cylinders giving the operator a bettergrip.Handwheels GN 321 Page 164GN 322 Page 168GN 323 Page 166GN 324 Page 170How to orderRevolving handleGN 798-KT-24-M10Code No. ÐMaterialÐd1 Ðd2 Ð50

®Stainless Steel-spindleRevolving handles GN 798.11.1d1 d2 d3 d4 l1 l2 l3 l416 M 6 ± 10 13 41,5 12 2,5 1518 M 6 M 8 10 14,5 56 13 2,5 1922 M 8 M 10 14 18,5 59 14 2,5 2124 M 8 M 10 14 18,5 74 16 2,5 2725 M 10 ± 16 20 84 16 2,5 30SpecificationPlastic KTTechnopolymer (Polyamide PA)temperature resistantup to 90° Cblack, matt finishSpindleStainless SteelGerman MaterialNo. 1.4305Stainless Steelcharacteristics Page 894Plasticcharacteristics Page 897InformationTypicalin design are our revolving handlesGN 798.1 (photo page 54) with their steppedshape consisting of two cylinders giving the operatora better grip.How to orderRevolving handleGN 798.1-KT-16-M6Code No. ÐMaterialÐd1 Ðd2 Ð51

®with hold in both positionsRetractable handles GN 798.3d1 d2 d3 l1 » l2 l3 l4 » l516 M 5 16 58 15 5 52,5 9,518 M 5 16 72,5 15 5 67 9,522 M 6 20 80,5 19,5 6 74 10,524 M 6 20 95,5 19,5 6 89 10,525 M 6 20 105,5 19,5 6 98,5 10,5SpecificationHandlePlastic KTTechnopolymer (Polyamide PA)temperature resistantup to 90° Cblack, matt finishrevolvingRetractable mechanismSteelblackenedPlasticcharacteristics Page 897InformationTypical in design are our retractable handlesGN 798.3 (photo page 54) with their steppedshape consisting of two cylinders giving the operatora better grip, especially when pulling the handleout from its locked position before it can be foldedback into the rest position.Retractable handles GN 798.3 are suitable whenthe handle must be withdrawn during automaticoperations. The handle is pulled out of its taperseating in the direction of the arrow and then tilted.A compression spring locks the handle in both endpositions.A positive lock is achieved in the operating positionby way of a taper seating.Handwheels GN 322.3(with retractable handle GN 598.3) Page 188How to orderRetractable handleGN 798.3-KT-22Code No. ÐMaterialÐd1 Ð52

®with hold in both positionsSt. Steel-Retractable handles GN 798.51.1d1 d2 d3 l1 » l2 l3 l4 » l516 M 5 16 58 15 5 52,5 9,518 M 5 16 72,5 15 5 67 9,522 M 6 20 80,5 19,5 6 74 10,524 M 6 20 95,5 19,5 6 89 10,525 M 6 20 105,5 19,5 6 98,5 10,5SpecificationHandlePlastic KTTechnopolymer (Polyamide PA)temperature resistantup to 90° Cblack, matt finishrevolvingRetractable mechanismStainless SteelGerman MaterialNo. 1.4305Stainless Steelcharacteristics Page 894Plasticcharacteristics Page 897InformationTypical in design are our retractable handlesGN 798.5 (photo page 54) with their steppedshape consisting of two cylinders giving the operatora better grip, especially when pulling the handleout from its locked position before it can be foldedback into the rest position.Retractable handles GN 798.5 are suitable whenthe handle must be withdrawn during automaticoperations. The handle is pulled out of its taperseating in the direction of the arrow and then tilted.A compression spring locks the handle in both endpositions.A positive lock is achieved in the operating positionby way of a taper seating.How to orderStainless Steel-Retractable handleGN 798.5-KT-25Code No. ÐMaterialÐd1 Ð53

®Revolving handles GN 798 P. 50Revolving handles with Stainless Steel-spindle GN 798.1 P. 51Retractable handles GN 798.3 P. 52Stainless Steel-Retractable handles GN 798.5 P. 5354

®1.1Revolving handles GN 598 P. 56Revolving handles with Stainless Steel-spindle GN 598.1 P. 57Retractable handles GN 598.3 P. 58Stainless Steel-Retractable handles GN 598.5 P. 59Retractable safety handles GN 598.7 P. 6055

®Revolving handles GN 598d1 d2 d3 d4 l1 l2 l3metricUNC14 M 6 ± ± 8 11 28 10 0,518 M 6 ±1 / 4 ´ 20 10 15 40 12 2,521 M 6 M 81 / 4 ´ 20 10 17 50 13 2,522 M 6 M 8 ± 10 18 56 13 2,523 M 8 M 105 / 16 ´ 18 13 19 65 14 2,526 M 8 M 103 / 8 ´ 16 13 21 80 16 2,528 M 10 ± ± 13 22 90 16 2,531 M 12 ±1 / 2 ´ 13 14 25 102 20 2,5SpecificationPlastic KUDuroplast (Phenolic PF)only sizes 18 ¸ 31temperature resistantup to 110° Cblack, shiny finishPlastic KTTechnopolymer (Polyamide PA)only sizes 14 ¸ 28temperature resistantup to 80° Cblack, matt finishSteel STonly sizes 18 ¸ 31Plastic coatedmatt black, textured finishSpindle steelzinc plated, blue passivatedPlasticcharacteristics Page 897InformationRevolving handles GN 598 (photo page 55) arenoted for their modern design and they blend inwell with the rectangular shaped rim handwheels.Steelhandles are mainly used on safetyhandwheels to increase imbalance and thus avoidfree wheeling.Cylindrical knobs GN 519(with internal thread) Page 72How to orderRevolving handleGN 598-KU-21-M8Code No. ÐMaterialÐd1 Ðd2 Ð56

®Stainless Steel-spindleRevolving handles GN 598.11.1d1 d2 d3 d4 l1 l2 l318 M 6 10 15 40 12 2,521 M 6 10 17 50 13 2,523 M 8 13 19 65 14 2,526 M 10 13 21 80 16 2,528 M 10 13 22 90 16 2,531 M 12 14 25 102 20 2,5SpecificationPlastic KUDuroplast (Phenolic PF)all sizestemperature resistantup to 110° Cblack, shiny finishPlastic KTTechnopolymer (Polyamide PA)only sizes 18 ¸ 28temperature resistantup to 80° Cblack, matt finishSpindleStainless SteelGerman MaterialNo. 1.4305Stainless Steelcharacteristics Page 894Plasticcharacteristics Page 897InformationRevolving handles GN 598.1 (photo page 55) arenoted for their modern design and they blend inwell with the rectangular shaped rim handwheels.How to orderRevolving handleGN 598.1-KU-21-M6Code No. ÐMaterialÐd1 Ðd2 Ð57

®with hold in both positionsRetractable handles GN 598.3d1 d2 d3 l1 » l2 l3 l4 » l518 M 5 16 57 15 5 52 9,521 M 5 16 67 15 5 62 9,522 M 5 16 73 15 5 68 9,523 M 6 20 87 19,5 6 80 10,526 M 6 20 102 19,5 6 95 10,528 M 8 26 118 26 10 106 16SpecificationHandlePlastic KUDuroplast (Phenolic PF)temperature resistantup to 110° Cblack, shiny finishrevolvingRetractable mechanismSteelblackenedPlasticcharacteristics Page 897InformationRetractable handles GN 598.3 (photo page 55)are suitable when the handle must be withdrawnduring automatic operations. The handle is pulledout of its taper seating in the direction of the arrowand then tilted. A compression spring locks thehandle in both end positions.A positive lock is achieved in the operating positionby way of a taper seating.Handwheels withSafety handle VDS+IR Page 186VRTP+IR Page 187Cranked handles GN 471.3 Page 150Cranked handles GN 472.3 Page 151Retractablesafety handles GN 598.7 Page 60How to orderRetractable handleGN 598.3-KU-26Code No. ÐMaterialÐd1 Ð58

®with hold in both positionsSt. Steel-Retractable handles GN 598.51.1d1 d2 d3 l1 » l2 l3 l4 » l523 M 6 20 87 19,5 6 80 10,526 M 6 20 102 19,5 6 95 10,528 M 8 26 118 26 10,5 106 16SpecificationHandlePlastic KUDuroplast (Phenolic PF)temperature resistantup to 110° Cblack, shiny finishrevolvingRetractable mechanismStainless SteelGerman MaterialNo. 1.4305Stainless Steelcharacteristics Page 894Plasticcharacteristics Page 897InformationRetractable handles GN 598.5 (photo page 55)are suitable when the handle must be withdrawnduring automatic operations. The handle is pulledout of its taper seating in the direction of the arrowand then tilted. A compression spring locks thehandle in both end positions.A positive lock is achieved in the operating positionby way of a taper seating.How to orderStainless Steel-Retractable handleGN 598.5-KU-26Code No. ÐMaterialÐd1 Ð59

®Retractable safety handles GN 598.7d1 d2 d3 l1 l2 » l3 l4 l5(arrested)23 M 6 20 79 88 22 13 5,526 M 6 20 93 102 22 13 5,5SpecificationHandlePlastic KUDuroplast (Phenolic PF)temperature resistantup to 110° Cblack, shiny finishrevolvingRetractable mechanismSteelblackenedPlasticcharacteristics Page 897InformationRetractable handles GN 598.7 (photo page 55)are suitable for applications where the handle mustnot remain in the operating position.In order to bring the handle into the operating positionit has to be turned first through 90° to a stopagainst a torsion spring and then it is pushedagainst spring pressure into its hold position. Bymaintaining the forward thrust on the handle, thehandwheelcan easily be rotated.When releasing the handle, the springs return itback to the retracted position.Hanwheels withsafety handle GN 322.7 Page 189How to orderRetractable safety handleGN 598.7-KU-23Code No. ÐMaterialÐd1 Ð60

®Revolving cylindrical handles GN 599.51.1d1 d2 l1 d3 l213 1814 M6 9 8 2016 23SpecificationPlasticTechnopolymer (Polyamide PA)temperature resistantup to 80° Cblack, matt finishSpindleStainless SteelStainless Steelcharacteristics Page 894Plasticcharacteristics Page 897InformationCylindrical handles GN 599.5 are mainly used onsmall handwheels (GN 736, GN 736.1) which areinstalled for control purposes where low torque isrequired (fingertip grip).How to orderRevolving cylindricalhandleGN 599.5-14-M6-9Code No. Ðd 1 Ðd 2 Ðl 1 Ð61

®Extract fromRevolving handles DIN 98Type D with plain shaftType E with threaded shaftd1 d2 h8 d3 d4 h13 l1 » l2 l3 InternalType D Type E hexagon16 7 M 6 10 49 11 5,5 320 8 M 8 13 61 13 6 425 10 M 10 16 75 14 8 532 13 M 12 20 95 21 10,5 636 16 M 16 22 106 26 11 8SpecificationSteel STall sizeszinc plated, blue passivatedAluminium ALall sizesfine turned, polishedPlastic KTTechnopolymer (Polyamide PA)only sizes 16 ¸ 32temperature resistantup to 110° Cblack, matt finishSpindle steelzinc plated, blue passivatedISO-FundamentalTolerances Page 888Plasticcharacteristics Page 89762InformationThis handle is supplied unassembled so that theshaft can be press fitted or screwed into a tappedblind bore prior to assembly.How to orderRevolving handleDIN 98-KT-32-DCode No. ÐMaterialÐd1 ÐType Ð

®Extract fromFixed handles DIN 391.1Type D with plain shaftType E with threaded shaftd1 d2 h8 d3 d4 h13 l1 » l2 l3 InternalType D Type E hexagon16 7 M 6 10 50 11 7 320 8 M 8 13 64 13 8 425 10 M 10 16 80 14 10 532 13 M 12 20 100 21 13 636 16 M 16 22 112 26 14 8SpecificationSteel STall sizesturned and polishedPlastic KTTechnopolymer (Polyamide PA)only sizes 20, 25, 32, Type Etemperature resistantup to 100° Cblack, matt finishshaft steel, blackenedISO-FundamentalTolerances Page 888Plasticcharacteristics Page 897How to orderFixed handleDIN 39-ST-25-ECode No. ÐMaterialÐd1 ÐType Ð63

®Revolving ball knobs GN 319.2d1 d2 d3 l1 l2 l325 M 6 10 11 37,5 1532 M 8 13 13 48 1940 M10 16 14 61 2450 M12 20 21 78 31SpecificationPlasticDuroplast (Phenolic PF)temperature resistantup to 110° Cblack, shiny finishShaft steelzinc plated, blue passivatedPlasticcharacteristics Page 897InformationRevolving ball knobs GN 319.2 can be utilizedinstead of revolving handles i. e. with handwheels.Revolving ball knobs have the same assemblydimensions as the handles DIN 39, DIN 98 andGN 598.How to orderRevolving ball knobGN 319.2-32-M8Code No. Ðd1 Ðd2 Ð64

®1.1Ball knobs DIN 319 and alternativesBall knobs (Duraplast, Technopolymer) DIN 319 P. 66Ball knobs (Steel, Aluminium, Stainless Steel) DIN 319 P. 67Ball knobs (Duroplast, Technopolymer, Press on type) DIN 319 P. 6865

®PlasticExtract fromBall knobs DIN 319Type C with tapped hole (no bush)Type E with tapped bushd1 d2 d3 d4 » h t1 t2Plastic Plastic min. min.KU KT KU KTType C Type C Type E Type EThread Thread Thread Thread12 M 4 ± ± ± ± ± ± 6 11,2 6,5 ±16 M 4 M 5 ± M 4 M 5 M 4 ± 8 15 7 620 M 5 M 6 ± M 5 M 6 M 5 M 5 12 18 9 7,525 M 5 M 6 M 8 M 6 M 8 M 6 M 6 15 22,5 11 930 M 8 ± ± ± ± ± ± 15 28 14,5 ±32 M 6 M 8 M 10 M 8 M 10 M 8 M 8 18 29 14,5 1235 M10 ± ± ± ± ± ± 18 32,5 18 ±40 M 8 M 10 M 12 M 10 M 12 M 10 ± 22 37 18 1550 M12 ± ± ± ± M12 ± 27 46 21 18SpecificationPlastic KUDuroplast (Phenolic PF)black (red optional,specify 'red' on order;not for all types)Flash removed and polishedBush (Type E)steel, zinc plated or brass (MS)(if ªbrassº is desired ad ªMSº onorder code)Plastic KTTechnopolymer (Polyamide PA)shock resistantblack, matt finishInsert (Type E)steel, zinc platedInformationPhoto page 65Ball knobs (Press on type)DIN 319 Type L and M Page 68Gear lever handles GN 310 Page 76How to orderBall knobDIN 319-KT-25-M6-ECode No. ÐMaterialÐd1 Ðd2 (d3) ÐType Ð66

®Steel/ Aluminium / Stainless SteelExtract fromBall knobs DIN 3191.1Type C with tapped holeType K with plain hole H7d1 d2 d3 H7 d4 h t1 t2Type C Type K min. min.16 M 4 B 6 8 15 7 920 M 5 B 8 12 18 9 1125 M 6 B 10 15 22,5 11 1432 M 8 B 12 18 29 14,5 1740 M 10 B 16 22 37 18 2250 M 12 B 20 27 46 21 28SpecificationSteel STpolishedAluminium ALpolishedStainless Steel NIGerman MaterialNo. 1.4305only Type Conly sizes 16, 20, 25, 32, 40matt shot-blastedISO-FundamentalTolerances Page 888Stainless Steelcharacteristics Page 894InformationPhoto page 65How to orderBall knobDIN 319-NI-25-M6-CCode No. ÐMaterialÐd1 Ðd2 (d3) ÐType Ð67

®Press on typeExtract fromBall knobs DIN 319Type L with tolerance ringType M with tapered bored1 d2 (Bore B) ± t1 d4 (Bore B) ± t2 d3 » hType L Type L Type L Type M Type M16 B 4 - 11 ± ± B 4 - 9 ± 8 1520 B 5 - 13 ± ± B 5 - 12 B 6 - 12 12 1825 B 6 - 16 B 8 - 15 B 10 - 15 B 6 - 16 B 8 - 16 15 22,532 B 8 - 15 B 10 - 20 B 12 - 20 B 8 - 17 B 10 - 17 18 2940 B 10 - 25 B 12 - 23 ± B 10 - 22 B 12 - 22 22 3750 B 12 - 20 B 16 - 23 ± ± ± 28 46SpecificationType LPlastic KUDuroplast (Phenolic PF)black, shiny finishTolerance ringspring steelType MPlastic KTTechnopolymer (Polyamide PA)shock resistantblack, matt finishISO-FundamentalTolerances Page 888Plasticcharacteristics Page 897InformationWhen ball knobs DIN 319 (photo page 65) type Land M are used the shaft does not require athread.The ball knobs are driven on to the shaft with lightmallet blows to the ball knobs. The shaft endshould have a radius or chamfered (30° C).Before the assembly of the knobs, type L the tollerancering is to be inserted into the drilling. Furtherit is to be noted that the button is put on perpendicularand / or axially parallel. Otherwise the knobmay break.Type M ball knobs are a cheaper solution, however,the pulling off force is less predictable.How to orderBall knobDIN 319-KU-40-B10-LCode No. ÐMaterialÐd1 Ðd2 ÐType ÐBall KnobDIN 319-KT-32-B10-MCode No. ÐMaterialÐd1 Ðd4 ÐType Ð68

®1.1Alternatives to ball knobsWaist shaped knobs GN 75 P. 86Mushroom type knobs GN 76 P. 87Elliptical shaped knobs GN 201 P. 74Taper knobs GN 419 P. 75Cylindrical knobs GN 519 P. 72Cylindrical knobs GN 519.1 P. 7369

®Domed gear knobs I.622d1 d2 d3 d4 h t1 t2 ± 0,5 t316 M 6 ± B 6 ± 12 25 16 3,5 1720 M 8 ± B 8 ± 14 32 20 3,5 2126 M 8 M 10 B 8 B 10 17 42 30 5 25 / 3034 M 10 M 12 B 10 B 12 21 55 35 8 40SpecificationPlastic Technopolymer(Polyamide PA)temperature resistant up to 80° Cblack SW RAL 9005shiny finishred RT RAL 3000shiny finishtypewith bore B onlywhite CL RAL 9002Cleanline shiny finish(not size 26-B 8)temperature resistant up to 50° CISO-FundamentalTolerances Page 888Plasticcharacteristics Page 897InformationDomed gear knobs I.622 are very often used in placeof ball knobs DIN 319 for use on gear leversand shafts.Operating knobs are very often chosen for ergonomicalreasons.Domed gear knobs I.622 with bore (B) are mountedby driving them over the shaft with a plastic hammer.A threaded shaft is not required. The shaftend should preferably be slightly rounded or chamfered(30°).How to orderELESA-Domedgear knobI.622-20-M8-SWCode No. Ðd1 Ðd2 (d3) ÐColour Ð70ELESA original design

®1.171

®Cylindrical knobs GN 519d1 d2 d3 l1 l2 l3 ± 0,5min.14 M 5 ± 11 28 12 1,518 M 6 M 8 15 40 25 3,521 M 6 M 8 17 50 26 / 35 3,5 / 7,523 M 8 M 10 19 65 30 / 40 7,526 M 10 M 12 21 80 55 7 / 1028 M 10 M 12 22 90 55 / 58 7 / 829 M 12 ± 23 116 58 831 M 12 ± 25 102 58 8SpecificationPlasticDuroplast (Phenolic PF)temperature resistantup to 110° Cblack, shiny finishPlasticcharacteristics Page 897InformationCylindrical knobs GN 519 (photo page 69) are veryoften used instead of ball knobs DIN 319 on operatinglevers, gear lever handles etc.It is, however, recommended that the male threadedend is kept sufficiently long to fully engage inthe internalthread of the cylindricalknob which willprevent breakage in the event of excessive sideload on the lever.Gear lever handles GN 310with cylindrical knob Page 76How to orderCylindrical knobGN 519-23-M8Code No. Ðd1 Ðd2 Ð72

®Press on typeCylindrical knobs GN 519.11.1d1 d2 d3 l1 l2Bore Bmin.18 B 8 ± 15 40 2821 B 10 ± 17 50 3523 B 10 B 12 19 65 4526 B 12 B 14 21 80 5028 B 15 B 16 22 90 60SpecificationPlasticTechnopolymer (Polyamide)shock resistanttemperature resistantup to 80° Cblack, matt finishISO-FundamentalTolerances Page 888Plasticcharacteristics Page 897InformationThe use of cylindrical knobs GN 519.1 (photo page69) eliminates a thread on the shaft.These cylindrical handles are driven over a leverusing a plastic mallet. The shaft end should beslightly rounded or chamfered (30°).The locating bore consists of single ribs to enhancethe elasticity, except the dimensions d1 = 23-B 12,26-B 14 and 28-B 16.In order to increase the elasticity the bore is fittedwith longitudinal ribs which give an absolutely firmseating of the handles on the shaft.How to orderCylindrical knobGN 519.1-26-B12Code No. Ðd1 Ðd2 Ð73

®Elliptical shaped knobs GN 201d1 d2 d3 l1 l2min.14 M 5 ± 7 34 2523 M 6 M 8 14 60 17 / 2226 M 8 M10 16 70 2530 M 10 M 12 16 65 2635 M 12 M 16 22 85 25SpecificationPlasticDuroplast (Phenolic PF)temperature resistantup to 110° Cblack, shiny finishPlasticcharacteristics Page 897InformationElliptical shaped knobs GN 201 (photo page 69)are often used on gear levers and handles insteadof ball knobs DIN 319.How to orderElliptical shaped knobGN 201-30-M10Code No. Ðd1 Ðd2 Ð74

®Taper knobs GN 4191.1d1 d2 d3 » h tmin.20 M 5 M 6 12 30 1825 M 6 M 8 15 38 1830 M 8 M10 18 46 1835 M 10 M 12 21 53 21SpecificationPlasticDuroplast (Phenolic PF)temperature resistantup to 110° Cblack, shiny finishPlasticcharacteristics Page 897InformationTaper knobs GN 419 (photo page 69) are oftenused on gear levers and handles instead of ballknobs DIN 319. They feature a modern andstreamlined shape.Gear lever handleswith Taper knobs GN 310 Page 76How to orderTaper knobGN 419-25-M8Code No. Ðd1 Ðd2 Ð75

®Gear lever handles GN 310Type A Ball knob DIN 319 Type C Taper knob GN 419 Type E Cylindrical knob GN 519d1 Length l1 d2 d3 d5 d7 l2 l3 l4 l7A C E A C E8 63 80 100 M 6 20 20 18 9 18 30 4010 80 100 125 M 8 25 25 21 11 22,5 38 5012 100 125 160 M 10 32 30 23 14 29 46 6514 125 160 200 M 12 35 35 26 16 32,5 53 8016 160 200 250 M 14 40 35 28 18 37 53 90SpecificationShaftsSteelblackenedKnobsPlasticDuroplast (Phenolic PF)black, shiny finishscrewed onBall knob DIN 319 Page 66Taper knob GN 419 Page 75Cylindricalknob GN 519 Page 72Plasticcharacteristics Page 897InformationThe choice of knobs can be made dependant ontheir function and / or their modern design.How to orderGear lever handleGN 310-10-125-ECode No. Ðd1 Ðl1 ÐType Ð76

®Stainless Steel-Gear lever handles GN 3101.1Type A Ball knob DIN 319 Type E Cylindrical knob GN 519d1 Length l1 d2 d3 d4 l2 l3 l4A E A E8 63 80 100 M 6 20 18 9 18 4010 80 100 125 M 8 25 21 11 22,5 5012 100 125 160 M 10 32 23 14 29 6514 125 160 200 M 12 35 26 16 32,5 80SpecificationShaftsStainless Steel NIGerman MaterialNo. 1.4305matt shot-blastedKnobsPlasticDuroplast (Phenolic)black, shiny finishscrewed onBall knob DIN 319 Page 66Cylindricalknob GN 519 Page 72Stainless Steelcharacteristics Page 894Plasticcharacteristics Page 897How to orderStainless Steel-Gear lever handleGN 310-12-100-A-NICode No. Ðd1 Ðl1 ÐType ÐStainless Steel Ð77

®AluminiumT-Handles GN 563.2Length l d1 H7 d2 h1 h2 s tBore B Thread Square min.55 B 6 M 6 M 8 33 22 14 1267 B 8 M8 ± 37 25 16 1680 B 8 M8 M10 41 26 20 16SpecificationAluminiumPlastic coatedblack SW RAL 9005textured finishblank BLtumbled,flash mark not visible· anodized ELnaturalcolourISO-FundamentalTolerances Page 888InformationT-Handles GN 563.2 (photo page 79) can be usedas either operating handles or for clamping purposes,producing high clamping forces.T-Handles are produced using a stamping processwhich yields a high density material of highstrength and a smooth surface.An originalELESA-Design, produced in metalwithpermission of ELESA s. p. a.T-Handles L.652(plastic Technopolymer) Page 80How to orderT-HandleGN 563.2-67-M8-SWCode No. ÐLength lÐd2 (d1) ÐFinish Ð78The sizes and types markedthus · are as a rulenot available from stockand subject to a minimumquantity order.

®1.1T-Handles in Technopolymer L.652 P. 80T-Handles in Technopolymerwith male thread L.652.p P. 81T-Handles in Aluminium GN 563.2 P. 7879

®TechnopolymerT-Handles L.652Length l d1 H9 d2 d3 h1 h2 s tBore B Thread Square min.40 B 6 ± M 6 ± ± 9 30 20 13 1655 B 6 ± M 6 M 8 ± 10 33 22 14 1867 B 6 B 8 M 8 ± ± 11 37 25 16 2080 B 6 B 8 M 8 M 10 M 12 14 41 26 20 25 / 1893 B 6 ± M 10 M 12 ± 13 45 28,5 21 25 / 18SpecificationPlastic Technopolymer(Polyamide PA)Glass fibre re-inforcedtemperature resistantup to 130° Cblack, mattBush in brassISO-FundamentalTolerances Page 888Plasticcharacteristics Page 897InformationT-Handles L.652 (photo page 79) can be used onoperating handles as well as on clamping fictures.These handles lend themselves ideally for veryhigh manualclamping forces.T-Handles GN 563.2(Aluminium) Page 78How to orderT-HandleL.652-80-B8Code No. ÐLength lÐd1 (d2) Ð80ELESA original design

®TechnopolymerT-HandlesL.652 p1.1l1 d l2 h1 h2 sSquare40 M 6 20 30 20 1355 M 8 20 33 22 1467 M 8 25 37 25 1680 M10 30 41 26 2093 M 12 30 45 28,5 21SpecificationPlastic Technopolymer(Polyamide PA)Glass fibre re-inforcedtemperature resistantup to 130° Cblack, mattThreaded stud in steelzinc plated,blue passivatedPlasticcharacteristics Page 897InformationT-Handles L.652 p (photo page 79) can be usedon operating levers as well as on clamping fictures.These handles lend themselves ideally for veryhigh manualclamping forces.T-Handles L.652with threaded bore (Technopolymer) Page 80T-Handles GN 563.2with threaded bore (Aluminium) Page 78How to orderT-HandleL.652 p-55-M8-20Code No. Ðl1 Ðd Ðl2 ÐELESA original design81

®Knurled knobsEKKd1 d2 d3 h1 h2 tmin.16 M 3 ± 8,5 13 8,5 618 M 4 ± 10,5 15,5 10,5 621 M 4 M 5 12,5 18 10,5 1025 M 6 M 8 14,5 22,5 14 1231 M 8 M 10 18,5 27 17 15 / 17SpecificationPlastic Technopolymer(Polyamide PA)Glass fibre re-inforcedtemperature resistant up to 130° Cblack- RAL 7021grey SGmattred RT RAL 3000· orange OR RAL 2004matt· grey GR RAL 7035matt· yellow GB RAL 1021matt· blue BL RAL 5024mattmattBush in brassPlastic charact. Page 89782InformationKnurled button nuts EKK (photo page 83) are usedfor manual applications for clamping or pulling. Theconcave top of the nut is a comfortable rest pointfor the thumb during a pulling application.The knurled section is a useful addition to facilitatethe installation of a nut when used for lighter clampingapplictions.Knobs GN 676.1(Steel, blackened) Page 85Stainless Steel-Knobs GN 676.5 Page 85How to orderKnurled knobEKK-25-M6-RTCode No. Ðd1 Ðd2 ÐFinish ÐThe sizes and types markedthus · are as a rulenot available from stockand subject to a minimumquantity order.ELESA original design

®1.1ERGOSTYLE ÒKnurled knobs (Technopolymer) EKK P. 82Knurled knob screws (Technopolymer) EKK.p P. 84Knobs (Steel) GN 676.1 P. 85Stainless Steel Knobs GN 676.5 P. 8583

®Knurled knob screwsEKK.plh 1h 2d 3d 2d 1d1 d2 Length l d3 h1 h2M 5 10 16 202112,5 18 10,5M 6 16 20 3025 M 6 16 20 25 30 14,5 22,5 14M 8 20 25 30 403118,5 27 17M10 30 40SpecificationPlastic Technopolymer(Polyamide PA)Glass fibre re-inforcedtemperature resistant up to 130° CblackgreySG RAL 7021· orange OR RAL 2004matt· grey GR RAL 7035matt· yellow GB RAL 1021matt· blue BL RAL 5024matt· red RT RAL 3000mattmattThreaded stud in steelzinc plated, blue passivated84InformationKnurled knob screws EKK.p (photo page 83) areused for manual applications for clamping or pulling.The concave top of the nut is a comfortablerest point for the thumb during a pulling application.The knurled section is a useful addition to facilitatethe installation of a nut when used for lighter clampingapplications.How to orderKnurled knob screwEKK.p-31-M8-20-SGCode No. Ðd1 Ðd2 ÐLength lÐColour ÐThe sizes and types markedthus · are as a rulenot available from stockand subject to a minimumquantity order.ELESA original design

®Steel GN 676.1Knobs Stainless Steel GN 676.51.1Type A without knurlType B with knurld1 d2 d3 h1 h2 tmin.21 M 4 M 5 12,5 18 10,5 1025 M 6 M 8 14,5 22,5 14 1231 M 8 M 10 18,5 27 17 15 / 17SpecificationGN 676.1SteelblackenedGN 676.5Stainless SteelGerman MaterialNo. 1.4305matt shot-blastedStainless Steelcharacteristics Page 894InformationKnobs GN 676.1 / GN 676.5 (photo page 83) areused in applications where a push or pull movementis required. Their concave top gives a morecomfortable thumb grip.The knurled model (Type B) can be used as an attractivelyshaped knurled knob with a threadedblind hole.Knurled knobs EKK Page 82How to orderKnobGN 676.1-21-M5-BCode No. Ðd1 Ðd2 ÐType ÐStainless Steel-KnobGN 676.5-31-M10-ACode No. Ðd1 Ðd2 ÐType Ð85

®Waist shaped knobs GN 75Type D with female threadType E with male threadd1 d2 d3 d4 h l tType D Type E min.16 M 5 M 6 10 18 10 720 M 6 M 8 12 24 12 925 M 6 M 8 14 29 14 932 M 8 M10 18 37 16 1236 M 10 M 12 20 42 18 15SpecificationSteelfine turnedblackenedInformationWaist shaped knobs GN 75 (photo page 69) areused as operating element for appliances, sliders,covers and other similar parts.Knobs GN 676.1 (Steel) Page 85Stainless Steel-Knobs GN 676.5 Page 85How to orderWaist shaped knobGN 75-25-M6-DCode No. Ðd1 Ðd2 (d3) ÐType Ð86

®Mushroom type knobs GN 761.1Type D with female threadType E with male threadd1 d2 d3 d4 h l tType D Type E min.17 M 5 M 5 10 14 9 721 M 6 M 6 12 17 10 1125 M 6 M 6 14 21 10 1133 M 8 M 8 18 29 14 12SpecificationPlasticDuroplast (Phenolic)temperature resistantup to 110° Cblack, shiny finishType Dbrass bush in brassType Ethreaded stud in steelzinc plated,blue passivatedPlasticcharacteristics Page 897InformationPhoto page 69How to orderMushroom type knobGN 76-25-M6-DCode No. Ðd1 Ðd2 (d3) ÐType Ð87

Cabinet ªUº handlesTubular handlesLedge handles1.2

®AluminiumCabinet ªUº handles GN 565b Length l a d h r tmin.20 100 4920 1124913 M 620 128 5113 1020 160 5126 112 5526 128 17 M 8 55 17 1226 160 5726 192 5726 300 17 M 8 57 17 1226 400 5726 500 17 M 8 57 17 12SpecificationAluminiumPlastic coatedblack SW RAL 9005textured finishred RT RAL 3000anodized ELnaturalcolourblank BLtumbledInformationCabinet ªUº handles GN 565 (photo page 91) areproduced from profiled aluminium extrusions; theirspecialfeatures are their rigidity and smooth surface.Good design and ergonomicalshaping were essentialforthe choice of the profile.The manufacturing process (bending) allows theproduction of special lengths in relatively smallquantities.Stainless Steel-Cabinet ªUº handlesGN 565.5 Page 94How to orderCabinet ªUº handleGN 565-20-100-SWCode No. Ðb ÐLength I ÐFinish Ð90

®1.2Cabinet ªUº handlesGN 565 P. 90GN 565.1 P. 92GN 565.2 P. 9391

®AluminiumCabinet ªUº handles GN 565.1b l1 a d h1 h2 l2 r20 100 49 11220 1124912413 5,41920 128 51 14020 160 51 17226 116 55 13026 1325514617 6,41726 164 57 17826 196 57 2101317SpecificationAluminiumPlastic coatedblack SW RAL 9005textured finishred RT RAL 3000anodized ELnaturalcolourblank BLtumbledInformationCabinet ªUº handles GN 565.1 (photo page 91)are a further development of GN 565 and can bemounted form the from the operator's side.Produced from profiled aluminium extrusions theirspecialfeatures are their rigidity and smooth surface.Good design and ergonomicalshaping were essentialforthe choice of the profile.The manufacturing process (bending) allows theproduction of special lengths in relatively smallquantities.Cabinet ªUº handles GN 565(Aluminium) Page 90How to orderCabinet ªUº handleGN 565.1-26-132-BLCode No. Ðb ÐLength l1 ÐFinish Ð92

®AluminiumCabinet ªUº handles GN 565.21.2b1 Length l a b2 d h1 h2 h3 h4 +1 r tmin.20 11220 12826 12826 16013 24 M 6 32 48 50 13,5 13 1017 32 M 8 34 54 57 18 17 12SpecificationAluminiumPlastic coatedblack SW RAL 9005textured finishanodized ELnaturalcolourblank BLtumbledInformationCabinet ªUº handles GN 565.2 (photo page 91)are a further development of GN 565. The angledcontact surface allows improved access even intight spaces such as corners.Produced from profiled aluminium extrusions theirspecialfeatures are their rigidity and smoothsurface.Good design and ergonomicalshaping were essentialforthe choice of the profile.When coated with epoxy resin its handability is furtherenhanced.The manufacturing process (bending) allows theproduction of special lengths in relatively smallquantities.How to orderCabinet ªUº handleGN 565.2-20-128-SWCode No. Ðb1 ÐLength lÐFinish Ð93

®Stainless Steel-Cabinet ªUº handles GN 565.5b Length l a d h r tmin.20 1124913 M 620 128 5113 10SpecificationStainless SteelGerman MaterialNo. 1.4301matt, shot-blastedStainless Steelcharacteristics Page 894InformationStainless Steel-Cabinet ªUº handles GN 565.5 areproduced from profiled stainless steel extrusions.The shape of this handle has good ergonomic features.The manufacturing process (bending) allows theproduction of special lengths in relatively smallquantities.Cabinet ªUº handles GN 565(Aluminium) Page 90How to orderStainless Steel-Cabinet ªUº handleGN 565.5-20-112Code No. Ðb ÐLength lÐ94

®Polyurethane foam rubberSoft-Cabinet ªUº handles GN 5641.2b Length l a d1 d2 h r tmin.25 112 50 525 128 16 M 6 10 54 7 1025 160 54 9SpecificationPolyurethane foam rubber(PUR)with steelre-inforcementsoft, tear resistant outer skinwith high resistance to abrasionTemperature resistantup to 80 °Cmatt blackElastomere (rubber)characteristics Page 896InformationCabinet ªUº handles GN 564 meet safety requirementson two accounts:The steelre-inforcement guarantees high resistanceto damage.The shock absorbing PU foam rubber coatingprevents injuries to the operator.The foam rubber (Polyurethane Integral FoamRubber Bayflex Ò ) is by nature of its surface finishextremely user friendly, non corroding and notaffected by the environment and in addition offersinsulating properties.How to orderSoft-Cabinet ªUº handleGN 564-25-128Code No. Ðb ÐLength lÐ95

®Cabinet ªUº handlesEPBType A mounting from the back (threaded blind bore)Type B mounting from the operator's sidel1 d1 d2 d3 d4 h1 h2 l2 l3 s t1 t2min.94 ±1 M 6 22 6,5 10,5 35 23,5 116 72 8 12 6,5117 ± 0,5 M 8 26 8,5 13,5 39 26,5 143 91 9 13 8,5150 ± 1 M 8 28 8,5 13,5 45 32 178 122 10 13 14179 ± 1 M8 28+ 0,5 8,5 13,5 51 35 208 150 10 13 16SpecificationPlastic Technopolymer(Polyamide PA)glass fibre reinforcedtemperature resistant up to 130° Cblack-grey, mattsimilar to RAL 7021bush (Type A) in brassColour of the cap:blackgreyDSG RAL 7021orange DOR RAL 2004grey DGR RAL 7035yellow DGB RAL 1021blue DBL RAL 5024red DRT RAL 3000mattmattmattmattmattmattInformationErgonomic considerations have led to the elegantdesign of the cabinet ªUº handles EPB.The use of caps in the various ªergostyleº coloursoffers additionalstyle creations.The caps for type A are monted on the handle, butsupplied loose for type B.How to orderCabinet ªUº handleEPB-117-A-DGRCode No. Ðl1 ÐType ÐColour Ðof the capELESA original design96

®1.297

®TechnopolymerCabinet ªUº handles M.843thdlbaLength l a b d h tmin.117 ± 0,55321 30 M 8179 ± 1 6213SpecificationPlastic Technopoymer(Polyamide PA)temperature resitant up to 120 °Cblack SW RAL 9005shiny finishorange OR RAL 2004shiny finishred RT RAL 3000shiny finishwithe CL RAL 9002Cleanline shiny finishyellow GB RAL 1021shiny finishgrey GR RAL 7035shiny finishblue BL RAL 5024shiny finishBushStandard specif.: BrassCleanline CL: Stainless SteelInformationCabinet ªUº handles M.843 are renowned for theirwell proven eliptical extrusion profile as well as theergonomicaldesign with their smooth and shinysurface. They lend themselves well for light coloursin contrast to the models in plastic.How to orderCabinet ªUº handleM.843 - 117 - RTCode No. ÐLength lÐColour Ð98ELESA original design

®1.299

®TechnopolymerCabinet ªUº handlesM.443 CHl1 b d1 d2 h1 h2 l2 l3 s t94 ± 1 21 6,5 10,5 38 13 109 74 6 7117 ± 1 26 8,5 13,5 41 15 137 93 7 8,5132 27 8,5 13,5 45 16 150 108 7 8,5179 28 8,5 13,5 50 17 196 151 7,5 8,5235 30 10,5 16,5 54 20 260 201 8,5 10,5SpecificationPA Plastic Technopolymer(Polyamide PA)glass fibre reinforcedtemperature resistant up to 150° Cblack SW RAL 9005orange OR RAL 2004grey GR RAL 7031PP Plastic Technopolymer(Polypropylene PP)glass fibre reinforcedtemperature resistant up to 100° Cblack SW RAL 9005Technopolymer SVselfextinguishingonly size 94, 117, 132, 179glass fibre reinforcedtemperature resistant up to 150° Cblack SW RAL 9005Technopolymer ESD(Polyamide PA)antistatic, only size Gr. 94 and 117temperature resistant up to 150° Cblack SW RAL 9005100InformationCabinet ªUº handles M.443 CH (photo page 102)are fitted to the drawers from the outside using capscrews.Cabinet ªUº handles of the type PP (Polypropylene)are, however, less viable from a mechanical andthermalviewpoint, but pricewise they are morecompetitive but are quite adequate for many applications.Cabinet handles of the type SV are made of a plasticmaterialtype UL 94 V-0 which is self extinguishing.The classification to UL 94 V-0 (UnderwritersLaboratories) covers the properties and durabilityagainst fire. According to their tests a plastic testpiece of a defined shape and dimension is setalight in a vertical position whereby the flame on ascale from V-0 has to extinguish itself within 10secs without leaving any burning droplets.Cabinet ªUº handles type ESD are made out of aconductive plastic material which prevents an electrostacticalloading.The imprint ªESD-Cº on thesurface of the handle defines the special antistaticalpropertiesaccording to EN 1000015/1 and IEC61340-5-1.How to orderCabinet ªUº handleM.443 CH-PA-117-SWCode No. ÐMaterialÐl1 ÐColour ÐELESA original design

®TechnopolymerCabinet ªUº handles M.543dl 3l 1l 2bths1.2l1 d b h l2 l3 s tTechnopolymer PA Techno- min.polymer PP94 ± 0,1 M 6 ± ± 21 36 107 79 6 10117 ± 0,5 M 6 M 8 M 6 25 38 134 102 7,5 12132 ± 0,5 M 8 ± ± 26 45 150 116 8 13SpecificationPA Plastic Technopolymer(Polyamide PA)glass fibre reinforcedtemperature resistant up to 130° Cblack SW RAL 9005orange OR RAL 2004PP Plastic Technopolymer(Polypropylene PP)glass fibre reinforcedtemperature resistant up to 100° Cblack SW RAL 9005bush in brassPlasticcharacteristics Page 897InformationCabinet handles M.543 (photo page 102) are theresult of a further development of M.443 CH. Themounting is, however, done from the inside of thedrawer.Cabinet ªUº handles type PP (Polypropylene) offerindeed less mechanical and thermal features,however are of low cost. Their characteristics aresufficient for many applications.Cabinet ªUº handles GN 728(Aluminium) Page 103How to orderCabinet ªUº handlesM.543-PA-117-M8-ORCode No. ÐMaterialÐl1 Ðd ÐColour ÐELESA original design101

®Cabinet ªUº Handles in Technopolymer M.443 CH P. 100Cabinet ªUº Handles in Technopolymer M.543 P. 101Cabinet ªUº Handles in Aluminium GN 728 P. 103Stainless Steel-Cabinet ªUº Handles GN 728.5 P. 103102

®Aluminium GN 728Cabinet ªUº handles Stainless Steel GN 728.5Type A mounting from the backType B mounting from the operator's side1.2l1 b d1 d2 d3 h1 h2 l2 l3 s tmin.120 22,5 M 6 6,4 11 42,5 13 147 108 8 10180 27 M 8 8,4 13,5 47,5 16 214 165 10 12SpecificationGN728AluminiumPressure die castingPlastic coatedblack SW RAL 9005textured finishblank BLtumbledGN 728.5Stainless Steel fine castingGerman MaterialNo. 1.4308matt shot-blastedStainless Steelcharacteristics Page 894InformationCabinet ªUº handles GN 728 (photo page 102) area low cost variant in metal.The installation can be carried out from the back(Type A) as well as from the operator's side (TypeB). The hole centers dimension is identical on allvariants. As a result they can be mounted in pairsopposite each other.Cabinet ªUº handles M.443 CH(Technopolymer) Page 100Cabinet ªUº handles M.543(Technopolymer) Page 101How to orderCabinet ªUº handleGN 728-120-A-SWCode No. Ðl1 ÐType ÐFinish ÐStainless SteelCabinet ªUº handleGN 728.5-180-BCode No. Ðl1 ÐType Ð103

®Cabinet ªUº handlesGN 565.3 P. 105GN 668 P. 106GN 728 P. 103104

®AluminiumCabinet ªUº handles GN 565.3Type A mounting from the backType B mounting from the operator's side1.2b l1 l2 l3 » a d1 d2 h1 h2 r tType A Type B Type A Type B Type B min.20 120 142 137 13 M 5 5,3 41 5 13 10SpecificationAluminiumPlastic coatedblack SW RAL 9005textured finishblank BLtumbledInformationCabinet ªUº handles GN 565.3 (photo page 104)are a further development of GN 565. They are suitablefor applications where lower ªlifting forces arerequired such as on lids or protective machine coversº.They can be mounted from the back (Type A) aswell as from the front (Type B). Since the dimensionl1 hole centres is identical on both types a pairof handles can also be mounted abutting eachother from the two sides.The countersunk holes of type B allow fixing withself tapping screws or countersunk rivets.The manufacturing process (bending) allows theproduction of special lengths in relatively smallquantities.How to orderCabinet ªUº handleGN 565.3-20-120-B-SWCode No. Ðb Ðl1 ÐType ÐFinish Ð105

®AluminiumFlat cabinet ªUº handles GN 668Type A mounting from the backType B mounting from the operator's sideb1 l1 a b2 d h1 h2 h3 l2 l3 l4 r tmin20 130 120 141 15320 170 10 23 M 5 45 6 7,5 160 181 193 15 1020 190 180 201 21320 210 10 23 M 5 45 6 7,5 200 221 233 15 10SpecificationAluminiumPlastic coatedblack SW RAL 9005textured finishblank BLtumbledHandle basePlastic (Technopolymer)black, mattInformationCabinet ªUº handles GN 668 (photo page 104) areproduced from aluminium extrusions.They can be mounted either from the back (TypeA) or by means of the handle base from theoperator's side (Type B).The manufacturing process (bending) allows theproduction of lengths other than standard in relativelysmall quantities.The manufacturing process (bending) allows theproduction of special lengths in relatively smallquantities.How to orderFlat cabinet ªUº handleGN 668-20-170-B-SWCode No. Ðb1 Ðl1 ÐType ÐFinish Ð106

®Cabinet ªUº handles GN 559Type A closed typeType B open ended type1.2l1 a1 a2 b d h1 h2 h3 h4 h5 l2 l3 l4 l5 t1 t2min. min.162 38 19 25 M 8 55 57 36 38 28 128 140 8 22 12 16SpecificationAluminiumPlastic coatedblack SW RAL 9005textured finishInformationA specialcharacteristic of the handle GN 559 is thethumb rest pad on the front of the leg.At the same time the extended leg offers an openended version with wide access.Handles GN 559 are known for their high stability.They are fixed by two M 8 screws whereby type Aoffers two alternative hole centers (l2 or l3).How to orderCabinet ªUº handleGN 559-162-B-SWCode No. Ðl1 ÐType ÐFinish Ð107

®Edge handles GN 481d1 ±0,5 l1 a1 a2 d2 h1 h2 ± 0,1 l230 100 10630 200 18 9 32 34,5 14,5 20630 300 30630 40040618 9 32 34,5 14,530 500 506SpecificationTube extrusionAluminiumEnd capsZinc die castingTube extrusion / end piecesPlastic coatedblack SW RAL 9005textured finishSelf tappingcountersunk screwsDIN 7500-1, type MInformationThe tube extrusion for edge handles GN 481 is formedin such a way that two countersunk self tappingscrews are used to cut their own counterthread in the extrusion to hold the end caps in position.If an edge handle for a cabinet of non-standardlength is required, a standard extrusion can simplybe shortened to fit.Edge handles GN 481 with special lengths on request.How to orderEdge handleGN 481-30-300-SWCode No. Ðd1 Ðl1 ÐFinish tube Ð108Four countersunk screwsDIN 7500-1 are includedpart of the order.

®Edge handles GN 4811.2Mounting instructionsIn order to align the edge handlewith the edge of the cabinet (l1 +2 mm), the end caps should, tostart with, only be loosely fitted.The mounting is carried out intwo steps as follows:1. Fit the end caps firmly to thecabinet2. Fix the extrusion axially byusing the countersunk screws.109

®Cabinet ªUº handles GN 426d1 Length l d2 h r tmin.20 20020 25020 30020 35028 25028 30028 35028 400M 8 68 22 15M10 78 32 15SpecificationAluminium ALPlastic coatedblack SW RAL 9005textured finishblank BLtumbledCabinet ªUº handles d1 =28are manufactured out ofaluminium tubing witha wall thickness of 4 mm andfitted with threaded aluminiumbushingsInformationCabinet ªUº handles GN 426 (photo page 111) areproduced from profiled aluminium extrusions.The manufacturing process (bending) allows theproduction of special lengths in relatively smallquantities.Stainless Steel-Cabinet ªUº handles GN 426.5 Page 113How to orderCabinet ªUº handleGN 426-AL-28-300-SWCode No. ÐMaterialÐd1 ÐLength lÐFinish Ð110

®1.2Cabinet ªUº handles GN 426 P. 110Cabinet ªUº handles GN 426.1 P. 112Stainless Steel-Cabinet ªUº handles GN 426.5 P. 113111

®Cabinet ªUº handles GN 426.1d1 Length l d2 h1 h2 r tmin.20 20020 300M 8 105 68 22 1528 25028 350 M 10 120 78 32 1528 500SpecificationAluminium ALPlastic coatedblack SW RAL 9005textured finishblank BLtumbledCabinet ªUº handles d1 =28are manufactured out ofaluminium tubing with a wallthickness of 4 mm and fittedwith threaded aluminiumbushingsInformationCabinet ªUº handles GN 426.1 (photo page 111)are produced from profiled aluminium extrusions.The manufacturing process (bending) allows theproduction of special lengths in relatively smallquantities.How to orderCabinet ªUº handleGN 426.1-AL-28-250-SWCode No. ÐMaterialÐd1 ÐLength lÐFinish tube Ð112