Sunflower Production Field Guide - Your "Home Page"

Sunflower Production Field Guide - Your "Home Page"

Sunflower Production Field Guide - Your "Home Page"

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A-1331 (EB-25 Revised)<br />

Sunfl ower<br />

<strong>Production</strong><br />

SEPTEMBER 2007

Foreword<br />

The fi rst edition of “Sunfl ower <strong>Production</strong> and Marketing<br />

Extension Bulletin 25” was published in 1975.<br />

This publication provided general information for<br />

growers, seedsmen, processors, marketing agencies<br />

and Extension personnel. Revised editions followed in<br />

1978, 1985 and 1994. Interest and knowledge about<br />

sunfl ower production and marketing in the U.S. has<br />

increased greatly in the past 30 years. Marketing and<br />

processing channels have stabilized and have become<br />

fairly familiar to growers since 1985, but pest problems<br />

have shifted and new research information has<br />

become available to assist in production decisions.<br />

This publication is a revision of the “Sunfl ower <strong>Production</strong><br />

and Marketing Bulletin” published in 1994.<br />

The purpose is to update information and provide a<br />

production and pest management guide for sunfl ower<br />

growers. This revised publication is directed primarily<br />

to the commercial production of sunfl ower, not to marketing<br />

and processing. It will attempt to give specifi c<br />

guidelines and recommendations on production practices,<br />

pest identifi cation and pest management, based<br />

on current information.<br />

This publication also is directed primarily toward sunfl<br />

ower production in the northern Great Plains of the<br />

U.S. However, much of the information is relevant to<br />

other production areas. All pesticides recommended<br />

have a U.S. Environmental Protection Agency label<br />

unless otherwise specifi ed. This publication contains<br />

certain recommendations for pesticides that<br />

are labeled ONLY for North Dakota. The users of<br />

any pesticide designated for a state label must have<br />

a copy of the state label in their possession at the<br />

time of application. State labels can be obtained<br />

from agricultural chemical dealers or distributors.<br />

USE PESTICIDES ONLY AS LABELED.<br />

Acknowledgements<br />

The editor is indebted to the contributors for writing<br />

sections of this publication. The editor also appreciates<br />

the efforts made by previous contributors, as<br />

these previous sections often were the starting point<br />

for current sections.<br />

i

ii<br />

Contributors<br />

Roger Ashley, Area Extension Agronomist, Dickinson<br />

Research Extension Center, Dickinson, ND 58601<br />

Duane R. Berglund, Professor Emeritus and Former<br />

Extension Agronomist, NDSU Extension Service,<br />

North Dakota State University, Fargo, ND 58105<br />

Carl Bradley, Former Extension Plant Pathologist,<br />

NDSU Extension Service, North Dakota State<br />

University, Fargo, ND 58105<br />

Gary Brewer, Former Department Chair and Professor,<br />

Department of Entomology, North Dakota State<br />

University, Fargo, ND 58105<br />

Lawrence Charlet, Research Entomologist,<br />

ARS-USDA, North Dakota State University,<br />

Fargo, ND 58105<br />

Greg Endres, Area Extension Agronomist, NDSU<br />

Research Extension Center, Carrington, ND 58421<br />

George Flaskerud, Extension Agricultural Economist,<br />

NDSU Extension Service, North Dakota State<br />

University, Fargo, ND 58105<br />

Dave Franzen, Extension Soils Specialist, NDSU<br />

Extension Service, North Dakota State University,<br />

Fargo, ND 58105<br />

Thomas Gulya, Research Plant Pathologist,<br />

ARS-USDA, North Dakota State University,<br />

Fargo, ND 58105<br />

James Hanzel, Sunfl ower Breeder, Proseed Inc.,<br />

Harvey, ND 58341<br />

Kenneth Hellevang, Extension Agricultural Engineer,<br />

NDSU Extension Service, North Dakota State<br />

University, Fargo, ND 58105<br />

Vernon L. Hofman, Professor Emeritus and Former<br />

Extension Agricultural Engineer, NDSU Extension<br />

Service, North Dakota State University, Fargo, ND<br />

58105<br />

Larry Kleingartner, Executive Director, National<br />

Sunfl ower Association, Bismarck, ND 58503<br />

Jan Knodel, Extension Entomologist, NDSU<br />

Extension Service, North Dakota State University,<br />

Fargo, ND 58105<br />

Greg Lardy, Extension Beef Cattle Specialist,<br />

Department of Animal and Range Sciences,<br />

North Dakota State University, Fargo, ND 58105<br />

George Linz, Wildlife Biologist, USDA-APHIS,<br />

Bismarck, ND 58501<br />

Sam Markell, Extension Plant Pathologist, NDSU<br />

Extension Service, North Dakota State University,<br />

Fargo, ND 58105<br />

Jerry Miller, Retired Sunfl ower Breeder, USDA-ARS,<br />

North Dakota State University, Fargo, ND 58105<br />

John Sandbakken, Marketing Specialist, National<br />

Sunfl ower Association, Bismarck, ND 58503<br />

Tom Scherer, Extension Irrigation Engineer, NDSU<br />

Extension Service, North Dakota State University,<br />

Fargo, ND 58105<br />

Don Tanaka, Soil Scientist, ARS-USDA, Northern<br />

Great Plains Research Laboratory, Mandan, ND<br />

58554<br />

Richard Zollinger, Extension Weeds Specialist,<br />

NDSU Extension Service, North Dakota State<br />

University, Fargo, ND 58105<br />

Former Editors: David W. Cobia, David E. Zimmer,<br />

Marcia McMullen and Duane R. Berglund<br />

Former Contributors: Ron R. Allen, William S. Ball,<br />

James Bauder, Al Black, David W. Cobia, William<br />

Danke, Alan Dexter, Carl Fanning, Gerhardt N. Fick,<br />

Basil Furgala, Phil Glogoza, James Helm, Harvey<br />

J. Hirning, Edna T. Holm, David H. Kinard, Arthur<br />

Lamey, Darnell Lundstrom, Dean McBride, Hugh<br />

McDonald, John Nalewaja, Berlin Nelson, David M.<br />

Noetzel, William K. Pfeifer, Lyle Prunty, Charlie E.<br />

Rogers, LeRoy W. Schaffner, Albert Schneiter, Robert<br />

and Jay Schuler, John T. Schulz, Tommy E. Thompson,<br />

Sebastian Vogel, Howard D. Wilkins, David E.<br />

Zimmer and Joseph C. Zubriski

Sunfl ower<br />

<strong>Production</strong><br />

Edited and Compiled by<br />

Duane R. Berglund<br />

Professor Emeritus and<br />

Former Extension Agronomist<br />

North Dakota State University<br />

Extension Service<br />

Extension Publication A-1331<br />

(EB-25 revised)<br />

September 2007<br />

North Dakota Agricultural<br />

Experiment Station<br />

and<br />

North Dakota State University<br />

Extension Service<br />

North Dakota State University<br />

Fargo, North Dakota 58105<br />

Contents<br />

page<br />

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i<br />

Acknowledgements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i<br />

Contributors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii<br />

I. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<br />

Historical perspective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<br />

Taxonomy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2<br />

Growth stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2<br />

Growing degree days . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

II. <strong>Production</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

World production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

U.S. production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Acreage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Seed yields/acre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Pounds of seed production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Processing plants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Prices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Sunfl ower marketing strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

III. Hybrid Selection and <strong>Production</strong> Practices . . . . . . . . . . . . . . 10<br />

Hybrid selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Oilseed (NuSun), traditional and confectionary . . . . . . . . . . . . 11<br />

Criterial for hybrid selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Semidwarf sunfl ower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Sunfl ower branching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

<strong>Production</strong> practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Seed quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Soils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Soil fertility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Fertilizer recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Fertilizer application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Water requirements for sunfl ower . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Soil water management for dryland sunfl ower . . . . . . . . . . . . . 16<br />

Irrigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Tillage, seedbed preparation and planting . . . . . . . . . . . . . . . . . 18<br />

Crop rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23<br />

Pollination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24<br />

IV. Pest Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

Insects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27<br />

Diseases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54<br />

Weeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80<br />

Birds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85<br />

Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88<br />

V. Hail Injury . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91<br />

VI. Herbicide Drift and Chemical Residue . . . . . . . . . . . . . . . . . . . . 95<br />

VII. Harvesting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101<br />

Maturity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101<br />

Harvesting attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101<br />

Combine adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103<br />

VIII. Drying and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105<br />

IX. Feeding Value of Sunfl ower Products<br />

in Beef Cattle Diets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109<br />

X. U.S. Grades and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112<br />

XI. Other Information Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113<br />

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115<br />

Appendix 1. Diseases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117<br />

iii

Introduction<br />

(Duane R. Berglund)<br />

Two primary types of sunfl ower are grown: (1) oilseed<br />

for vegetable oil production and (2) nonoilseed for<br />

human food and bird-food markets (Figure 1). The oilseed<br />

hybrids may be of three fatty acid types: linoleic,<br />

mid-oleic (NuSun) or high oleic. They are usually<br />

black-seeded and have a thin hull that adheres to the<br />

kernel. Seed of the oilseed varieties contains from 38<br />

percent to 50 percent oil and about 20 percent protein.<br />

Some black-seeded oil types go into the hulling market<br />

for birdseed. Nonoilseed sunfl ower also has been<br />

referred to as confectionery sunfl ower, and is usually<br />

white striped and/or comes in large-seeded varieties.<br />

1<br />

2<br />

Nonoilseed sunfl ower generally has a relatively thick<br />

hull that remains loosely attached to the kernel, permitting<br />

more complete dehulling. Seed of the nonoilseed<br />

hybrids generally is larger than that of the oilseed<br />

types and has a lower oil percentage and test weight.<br />

Sunfl ower is a major source of vegetable oil in<br />

the world. Worldwide production of sunfl ower has<br />

increased since the last revision of this publication<br />

and peaked during the 1998-1999 period. The former<br />

Soviet Union remains the highest producer, followed<br />

by Argentina and then the U.S., which is third in<br />

production worldwide. Domestic use and exportation<br />

of nonoilseed sunfl ower also have increased. The majority<br />

of U.S. production of sunfl ower oil is exported,<br />

although domestic use is increasing.<br />

The following chapters provide a historical perspective<br />

and background of the sunfl ower as a viable<br />

economic crop and provide the current information<br />

on worldwide and U.S. production, U.S. production<br />

practices, current pest identifi cation and pest management<br />

practices, hail injury, herbicide use and damage,<br />

harvesting, drying, storing, and U.S. grades and<br />

standards for market.<br />

Historical Perspective<br />

Sunfl ower, native to North America, is the state<br />

fl ower of Kansas and grows wild in many areas of<br />

the U.S. Sunfl ower has a long and varied history as<br />

an economic plant, but the time and place of its fi rst<br />

cultivation is uncertain. Sunfl ower was used by North<br />

■ Figure 1. The two classes of sunfl ower based on seed<br />

characteristics: (1) oilseed hybrids grown as a source<br />

for oil and meal, and (2) nonoilseed hybrids-grown for<br />

human and bird food. Wholeseed and kernel types for<br />

both are shown. (Gerhardt Fick)<br />

Introduction<br />

1

2<br />

American Indians before colonization of the New<br />

World. Spanish explorers collected sunfl ower in North<br />

America and by 1580, it was a common garden fl ower<br />

in Spain (Figure 2). Early English and French explorers,<br />

fi nding sunfl ower in common use by the American<br />

Indians, introduced it to their respective lands. It<br />

spread along the trade routes to Italy, Egypt, Afghanistan,<br />

India, China and Russia. Sunfl ower developed as<br />

a premier oilseed crop in Russia and has found wide<br />

acceptance throughout Europe. Oilseed sunfl ower has<br />

been an economically important crop in the U.S. since<br />

1966. Before 1966, sunfl ower acreage in the U.S. was<br />

devoted primarily to nonoilseed varieties.<br />

The center of sunfl ower origin has been identifi ed<br />

as limited to the western Plains of North America,<br />

but whether the domesticated type originated in the<br />

Southwest or in the Mississippi or Missouri River<br />

valleys has not been determined. The wild form of the<br />

cultivated sunfl ower is well-known, which is not true<br />

with most of our cultivated crop species today.<br />

■ Figure 2. A 1586 drawing of sunfl ower.<br />

(Mattiolus from Heiser)<br />

The American Indians used sunfl ower as a foodstuff<br />

before the cultivation of corn. Sunfl ower also was used<br />

as a medicinal crop, source of dye, oil for ceremonial<br />

body painting and pottery, and as a hunting calendar.<br />

When sunfl ower was tall and in bloom, the bison fed<br />

on it, and according to stories told, the fat and the<br />

meat were good.<br />

Cultivation of sunfl ower was undertaken by New<br />

World settlers as a supplementary food. Later, sunfl<br />

ower was grown primarily as a garden ornament. It<br />

also was grown as an ensilage crop in the late 1800s<br />

and early 1900s.<br />

Expanded world production of sunfl ower resulted<br />

primarily from development of high-oil varieties by<br />

plant scientists and more recently by the development<br />

of hybrids. Sunfl ower is widely grown in the world<br />

where the climates are favorable and a high quality oil<br />

is desired.<br />

Taxonomy<br />

The cultivated sunfl ower (Helianthus annuus L.) is<br />

one of the 67 species in the genus Helianthus. All<br />

are native to the Americas and most are found in the<br />

U.S. It is a member of the Compositae family and<br />

has a typical composite fl ower (Figure 3). Jerusalem<br />

artichoke (H. tuberosus L.), another species, is grown<br />

on a limited basis for food and livestock feed in the<br />

U.S. A few species are grown as ornamentals and the<br />

rest are weeds, usually found in pastures or disturbed<br />

areas.<br />

The basic chromosome number for the Helianthus<br />

genus is 17. Diploid, tetraploid and hexaploid species<br />

are known. The majority of the species are perennial,<br />

with only about a dozen annual species. Plant breeders<br />

have made interspecifi c crosses within the genus and<br />

have transferred such useful characteristics as higher<br />

oil percentage, cytoplasmic male sterility for use in<br />

production of hybrids, and disease and insect resistance<br />

to commercial sunfl ower.<br />

Growth Stages<br />

The division of growth into vegetative and reproductive<br />

stages as developed by Schneiter and Miller is<br />

shown in Figure 4. This scheme is important as it<br />

gives producers, scientists and the industry a common<br />

basis to discuss plant development.

ay fl ower<br />

petal<br />

disk fl orets<br />

receptacle<br />

Table 1. Growing Degree Days: Sunfl ower Growth and Development<br />

Sunfl ower Plant<br />

Ave. days and GDD** units<br />

accum. from planting<br />

GDD<br />

Stage Description units Days<br />

VE Emergence 167 10<br />

V4 4 True Leaves 349 20<br />

V8 8 True Leaves 545 28<br />

V12 12 True Leaves 690 34<br />

V16 16 True Leaves 772 38<br />

V20 20 True Leaves 871 44<br />

R1 Miniature Terminal Bud 919 46<br />

R2 Bud

4<br />

Vegetative Stages<br />

True leaf — 4 cm<br />

V-12<br />

Reproductive Stages<br />

R-5.1<br />

R-7<br />

V-E<br />

V-2<br />

V-4<br />

R-1 R-2<br />

R-3 R-3 Top View R-4 Top View<br />

R-5.5 R-5.9 R-6<br />

R-8 R-9<br />

■ Figure 4. Stages of sunfl ower development.<br />

(A. A. Schneiter and J.F. Miller.)<br />

Less<br />

than<br />

2cm<br />

R-2 R-3<br />

More<br />

than<br />

2cm

Description of sunfl ower growth stage<br />

The total time required for development of a sunfl ower plant and the time between the various<br />

stages of development depends on the genetic background of the plant and growing season environment.<br />

When determining the growth stage of a sunfl ower fi eld, the average development of a<br />

large number of plants should be considered. This staging method also can be used for individual<br />

plants. The same system can be used for classifying either a single head or branched sunfl ower.<br />

In the case of branched sunfl ower, make determinations using only the main branch or head. In<br />

stages R-7 through R-9, use healthy, disease-free heads to determine plant development if possible<br />

because some diseases can cause head discoloration. Also, in a number of recently released and<br />

grown hybrids, the stay-green characteristic is present, which means the yellowing or browning of<br />

the bracts may not be a good indicator of plant maturity.<br />

Stage Description<br />

V (number) These are determined by counting the number of true leaves at least<br />

Vegetative Stages 4 cm in length beginning as V-1, V-2, V-3, V-4, etc. If senescence of<br />

(e.g., V-1, V-2, V-3, etc.) of the lower leaves has occurred, count leaf scars (excluding those<br />

where the cotyledons were attached) to determine the proper stage.<br />

R-1 Reproductive Stages The terminal bud forms a miniature fl oral head rather than a cluster of<br />

leaves. When viewed from directly above, the immature bracts have a<br />

many-pointed starlike appearance.<br />

R-2 The immature bud elongates 0.5 to 2.0 cm above the nearest leaf<br />

attached to the stem. Disregard leaves attached directly to the back of<br />

the bud.<br />

R-3 The immature bud elongates more than 2 cm above the nearest leaf.<br />

R-4 The infl orescence begins to open. When viewed from directly above,<br />

immature ray fl owers are visible.<br />

R-5 (decimal) This stage is the beginning of fl owering. The stage can be divided into<br />

(e.g., R-5.1, R-5.2, R-5.3, etc.) substages dependent upon the percent of the head area (disk fl owers)<br />

that has completed or is in fl owering. Ex. R-5.3 (30%), R-5.8 (80%),<br />

etc.<br />

R-6 Flowering is complete and the ray fl owers are wilting.<br />

R-7 The back of the head has started to turn a pale yellow.<br />

R-8 The back of the head is yellow but the bracts remain green.<br />

R-9 The bracts become yellow and brown. This stage is regarded as<br />

physiological maturity.<br />

From Schneiter, A.A., and J.F. Miller. 1981. Description of Sunfl ower Growth Stages. Crop Sci. 21:901-903.<br />

Growth Stages<br />

5

6<br />

<strong>Production</strong><br />

World <strong>Production</strong><br />

(John Sandbakken and Larry Kleingartner)<br />

The sunfl ower is native to North America but commercialization<br />

of the plant took place in Russia. Sunfl ower<br />

oil is the preferred oil in most of Europe, Mexico and<br />

several South American countries. Major producing<br />

countries or areas are the former Soviet Union,<br />

Argentina, Eastern Europe, U.S., China, France and<br />

Spain (Table 2). These seven countries/areas of the<br />

world produce about 80 percent of the world’s oilseed<br />

and nonoilseed sunfl ower. Historically, the former Soviet<br />

Union has been the No. 1 producer of sunfl ower,<br />

producing about 35 percent of the world’s production<br />

annually. During much of the 1970s, the U.S. was<br />

the world’s second largest producer, but in the 1980s,<br />

Argentina became fi rmly entrenched in second place.<br />

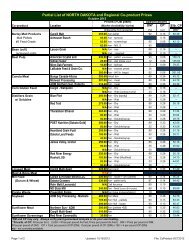

Table 2. World <strong>Production</strong> of All Sunfl ower<br />

U.S. <strong>Production</strong><br />

Acreage<br />

The fi rst sustained commercial production of oilseed<br />

sunfl ower in the U.S. occurred in 1966, when about<br />

6,000 acres were grown. Total combined acreage of<br />

oilseed and nonoilseed sunfl ower increased gradually<br />

in the late 1960s and expanded rapidly in the 1970s,<br />

reaching a peak in 1979 at 5.5 million acres. The U.S.<br />

share of world production has declined in recent years<br />

as production in Argentina and other countries has<br />

increased. During the peak period of U.S. production,<br />

the U.S. produced about 15 percent of the world’s<br />

sunfl ower production. In 2005, the U.S. market share<br />

was only 6 percent.<br />

The rapid acreage increase in the late 1970s was<br />

stimulated by a variety of factors. Favorable yields in<br />

1977 and 1978 brought about by improved hybrids<br />

and favorable weather conditions were key factors,<br />

along with excellent prices when compared with competitive<br />

crops.<br />

1996- 1997- 1998- 1999- 2000- 2001- 2002- 2003- 2004- 2005-<br />

2006-<br />

2007<br />

1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 Forecast<br />

Argentina 5.45 5.68 7.13 5.80 2.94 3.73 3.34 2.98 3.75 3.82 4.20<br />

Eastern Europe 2.92 2.18 2.59 2.75 1.67 1.86 2.02 2.67 2.27 2.11 2.17<br />

European Union 3.87 4.08 3.44 3.10 3.27 3.03 3.72 4.07 4.07 3.72 4.06<br />

China, Peoples<br />

Republic of<br />

1.42 1.17 1.46 1.77 1.95 1.75 1.95 1.82 1.70 1.83 1.85<br />

former USSR 5.37 5.41 5.74 6.89 7.27 4.94 7.19 9.35 8.00 11.32 11.20<br />

United States 1.60 1.67 2.39 1.97 1.61 1.55 1.11 1.21 .93 1.82 .92<br />

India 1.30 1.16 1.17 .87 .81 .73 1.06 1.16 1.45 1.50 1.43<br />

Turkey .67 .67 .85 .82 .63 .53 .83 .56 .64 .80 .90<br />

Other 1.99 1.87 2.83 2.98 3.01 3.55 2.74 3.07 3.58 3.25 3.77<br />

World Sunfl ower 24.63 23.89 27.60 26.95 23.16 21.80 23.95 26.88 26.39 30.16 30.49<br />

<strong>Production</strong><br />

(million metric tons)

Changes in the 1990 government farm program, which<br />

allowed planting fl exibility while providing price support,<br />

led to an increase in sunfl ower acreage in 1991<br />

relative to 1990. The government program established<br />

a marketing loan and a loan defi ciency payment for<br />

sunfl ower and other oilseed crops.<br />

The bulk of U.S. sunfl ower production occurs in North<br />

Dakota, South Dakota, Minnesota, Kansas, Colorado,<br />

Nebraska and Texas. Small acreages are grown<br />

in several other states (Table 3). The majority of the<br />

acreage harvested is for oil production versus nonoil<br />

uses. In 2005, the USDA reported that 2,032,000 acres<br />

of oil sunfl ower and 578,000 of nonoil sunfl ower were<br />

harvested (Table 4).<br />

Seed Yield/Acre<br />

Annual average sunfl ower yields from 1996 to 2005<br />

ranged from 1,140 to 1,564 pounds per acre for<br />

oilseed and from 997 to 1,455 pounds per acre for<br />

Table 3. Total Planted Sunfl ower Acreage by States 1994-2006<br />

nonoilseed sunfl ower. Average yields per acre during<br />

the 1996-2005 period were 1,349 pounds for oilseeds<br />

and 1,220 pounds for nonoilseed sunfl ower (Figure 5).<br />

Pounds of <strong>Production</strong><br />

U.S. production of oilseed sunfl ower ranged from<br />

1,763 million pounds (799,700 metric tons) in 2004 to<br />

4,486 million pounds (2,035,000 metric tons) in 1998<br />

(Table 5). Nonoilseed production ranged from 286<br />

million pounds (130,000 metric tons) in 2004 to 844<br />

million pounds (383,000 metric tons) in 1999.<br />

Processing Plants<br />

Four oil extraction plants in North Dakota, Minnesota<br />

and Kansas process oilseed sunfl ower. These<br />

four plants have a combined crushing capacity of<br />

1,900,000 metric tons per year, according to industry<br />

estimates. Several smaller plants are located throughout<br />

the main sunfl ower production region.<br />

1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

North Dakota 1,590 1,450 1,180 1,470 1,990 1,700 1,330 1,070 1,370 1,210 880 1,140 900<br />

South Dakota 940 960 700 825 940 920 720 715 640 505 435 550 535<br />

Kansas 260 300 265 200 180 280 250 335 193 215 171 300 152<br />

Minnesota 500 440 150 105 130 130 95 60 70 90 60 135 90<br />

Colorado 100 115 110 85 160 270 220 195 130 130 135 215 100<br />

Texas 34 44 31 88 47 75 60 108 35 59 41 145 54<br />

Nebraska 75 90 47 55 70 101 90 82 60 66 56 99 53<br />

Other States 68 79 53 60 51 77 75 68 60 91 95 125 100<br />

Total U.S.<br />

Thousand Acres<br />

3,567 3,478 2,536 2,888 3,568 3,553 2,840 2,633 2,580 2,344 1,873 2,709 1,984<br />

Table 4. Harvested USA Sunfl ower Acreage 1994-2006<br />

1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

Oilseed 2,943 2,829 1,934 2,212 2,897 2,695 2,116 2,060 1,815 1,874 1,424 2,032 1,587<br />

Nonoilseed 487 539 545 580 595 746 531 495 365 323 287 578 277<br />

Total<br />

Thousand Acres<br />

3,430 3,368 2,479 2,792 3,492 3,441 2,647 2,555 2,180 2,197 1,711 2,610 1,864<br />

<strong>Production</strong><br />

7

8<br />

Table 5. U.S. Sunfl ower <strong>Production</strong> 1994-2006<br />

■ Figure 5. Average U.S. Sunfl ower Yield 1996-2005<br />

in Pounds Per Acre.<br />

Prices<br />

1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006<br />

Oilseed<br />

---------------------------------------------------- Million Pounds ----------------------------------------------------<br />

4,223 3,398 2,844 2,986 4,486 3,498 2,910 2,804 2,070 2,260 1,763 3,178 1818<br />

Nonoilseed 612 611 716 691 787 844 635 615 420 406 286 841 295<br />

Total 4,835 4,009 3,560 3,677 5,273 4,342 3,545 3,419 2,490 2,666 2,049 4,018 2113<br />

Historically, sunfl ower depended heavily on the<br />

export market for either seed or oil. With the advent<br />

of NuSun and high oleic sunfl ower, the market has<br />

switched almost exclusively to a U.S. and Canadian<br />

market. Both of these oils are very stable and do not<br />

require hydrogenation as do competitive oils, such<br />

as traditional soybean and canola oils, when used in<br />

a frying application. Sunfl ower prices now are more<br />

determined by their relationship to corn oil prices.<br />

Large domestic users tend to buy in advance, thus<br />

prices are not directly affected by the Chicago soybean<br />

oil contract and are not as likely to be as volatile.<br />

More opportunities are available to presell a portion<br />

of the crop well before planting begins. This ensures<br />

a domestic user of a supply and allows a producer to<br />

“lock in” a price for a portion of his production. Storage<br />

of sunfl ower is necessary. The domestic market<br />

needs a 12-month supply of oil and crushers will need<br />

a steady supply of seed. Crushers likely will have to<br />

provide producers with storage premiums for delivery<br />

in the out-of-harvest months. Oilseed sunfl ower producers<br />

have the advantage of multiple market options:<br />

the hulling market, the crush market or the bird food<br />

market. Supply and demand drive prices in all three<br />

markets. These markets are very specifi c and unique,<br />

with different values associated with them. Farmers<br />

should have samples of their crop graded to determine<br />

quality and talk directly to buyers to fi nd out what<br />

they want in terms of seed specifi cations.<br />

Nonoilseed (confection) sunfl ower production is<br />

geared to the “in-shell” markets. Today’s confection<br />

hybrids produce a signifi cant level of large seeds.<br />

Growers often are paid on a percentage of large seed.<br />

Quality standards for confection sunfl ower are high<br />

and allow little tolerance for off-color and insect<br />

damage. Most confection sunfl ower is produced on<br />

a contract basis. The seasonal average price during<br />

the 1994/95 to 2002/03 period ranged from $5.89 to<br />

$12.30 per hundredweight for oilseed sunfl ower and<br />

from $11.90 to $15.20 per hundredweight for nonoilseed<br />

sunfl ower. During that period, the nonoilseed<br />

price exceeded the oilseed price by $3.85 per hundredweight<br />

on average.

Sunfl ower Marketing Strategy<br />

(George Flaskerud)<br />

Sunfl ower marketing strategies usually use the cash<br />

forward contract for locking in a price prior to harvest.<br />

Use of this contract may be appropriate on a portion<br />

of the sunfl ower crop, but so may the use of other marketing<br />

tools, such as hedging with futures or use of<br />

options (puts or calls). The best marketing alternative<br />

depends in part on the basis, which is the relationship<br />

between a cash and futures price.<br />

Since a sunfl ower futures market does not exist, relationships<br />

between the sunfl ower cash price and other<br />

closely related futures markets need to be considered.<br />

Using the futures market of a different commodity for<br />

hedging is cross-hedging, while the cash and futures<br />

price relationship is the cross-basis. Two futures<br />

contracts are examined: soybean oil futures, which<br />

are traded on the Chicago Board of Trade, and canola<br />

futures, which are traded on the Winnipeg Commodity<br />

Exchange.<br />

Historic prices were analyzed during 1997 through<br />

April 2004 to identify patterns and relationships<br />

useful for developing marketing strategies. Prices<br />

were standardized in U.S. dollars per hundredweight<br />

(US$/cwt).<br />

Correlations indicate that changes in NuSun prices<br />

(40 percent oil) at Enderlin, N. D., are the most closely<br />

correlated with canola futures (correlation = .91). Soybean<br />

oil futures were a distant, second-best correlation<br />

(.75). These correlations suggest that canola futures<br />

should provide the most risk reduction for cross-hedging<br />

cash sunfl ower prices. However, with the current<br />

situation for sunfl owers, soybean oil and canola need<br />

to be evaluated to determine which futures contract<br />

likely is to be the most profi table.<br />

Price quotations for canola futures are in Canadian<br />

dollars (C$) per metric ton. The price quotation for<br />

November canola was C$352 on August 25, 2003,<br />

and the exchange rate was 1.41 C$/US$. In U.S.<br />

dollars per hundredweight, this quotation would be<br />

US$11.32 (C$352 divided by 1.41 divided by 22.046<br />

= US$11.32).<br />

Seasonal patterns for Enderlin NuSun prices (Figure<br />

6) revealed a broad range of price behavior during individual<br />

marketing years (October-September). Highs<br />

occurred during August in 2000-01 and 2001-02,<br />

April in 1999-00, October in 1998-99 and November<br />

in 2002-03. The distribution of prices reveals that the<br />

pattern, on average, is to decline to lows in October<br />

and then increase to a peak in June before declining<br />

into the next marketing year.<br />

The range in the monthly average, excluding the low<br />

and the high, was only $.53 per cwt. The within-year<br />

variations were considerably greater. The average<br />

within-year range was $3.07. During 2000-01 and<br />

2001-02, when prices trended up, the average withinyear<br />

range was $3.98. During the other years, the<br />

average within-year range was $2.47.<br />

The tendency for the Enderlin NuSun cross-basis<br />

relative to canola futures (Figure 7) was to decline to a<br />

low in September and to remain nearly as low during<br />

October and November, and then to increase to a high<br />

in February-April before generally declining into the<br />

end of the marketing year. During three of the fi ve<br />

years, the cross-basis was near its low in October. The<br />

range of the cross-basis was the narrowest during September<br />

and the widest during May. During October,<br />

the average cross-basis per cwt ranged from -$1.64 to<br />

-$.16 and averaged -$.99.<br />

Relative to soybean oil futures, the Enderlin average<br />

cross-basis showed a pattern of marketing year lows<br />

per cwt in November (-$9.15), April (-$9.25) and September<br />

(-$9.16) and highs in February (-$8.08) and<br />

July (-$8.30). During October, the average cross-basis<br />

ranged from -$14.47 to -$6.59 and averaged -$8.95.<br />

■ Figure 6. Seasonal Behavior of NuSun Prices at<br />

Enderlin, ND.<br />

<strong>Production</strong><br />

9

10<br />

■ Figure 7. NuSun Cross-Basis at Enderlin, ND<br />

Relative to Nearby WCE Canola Futures.<br />

Variability, as measured by the standard deviation, was<br />

greater for the cross-basis relative to soybean oil futures<br />

than for the cross-basis relative to canola futures.<br />

This suggests lower basis risk when cross-hedging<br />

with canola futures than with soybean oil futures.<br />

From this information, marketing strategies can be<br />

developed. The seasonal pattern for Enderlin NuSun<br />

prices suggests that preharvest sales should be considered<br />

when prices are above the fi ve-year average<br />

price. Prices declined into harvest during two of three<br />

years that prices were above the average early in the<br />

marketing year.<br />

Use of the cash forward contract or cross-hedge would<br />

be appropriate on that portion of the sunfl ower crop<br />

that can be safely produced, i.e., on 20 percent to 40<br />

percent of the crop. The cash forward contract would<br />

be preferred if it refl ects an average or better cross-basis<br />

relative to sunfl ower oil futures or canola futures.<br />

A greater portion of the crop could be sold on a cash<br />

forward contract if it includes an act-of-God clause.<br />

In addition to the cash forward contract or crosshedge,<br />

a call option could be purchased to preserve<br />

upside potential. In the case of the cross-hedge, the<br />

call option would be purchased in the same futures<br />

contract. In the case of the cash forward contract, the<br />

call option could be purchased in either the soybean<br />

oil futures or canola futures. The put option is an alternative<br />

to using a cash forward contract or cross-hedge<br />

in combination with a call option.<br />

For sunfl owers that are not cash forward contracted,<br />

storage is an alternative. On average, storage was profitable<br />

during the 1998-99 to 2002-03 marketing years.<br />

However, the most profi table period of storage varied<br />

considerably. The most profi table sell or store strategy<br />

was to sell the 1998 crop at harvest, store the 1999<br />

crop until January, store the 2000 and 2001 crops until<br />

August and store the 2002 crop for one month. Sell or<br />

store decisions are diffi cult and require frequent evaluation<br />

of fundamentals, cash prices, futures prices,<br />

basis and storage costs.<br />

Additional marketing alternatives are available but beyond<br />

the scope of this article. Further information can<br />

be found in NDSU Extension publication EC-1270,<br />

“Managing Sunfl ower Price Risk.”

Hybrid Selection and<br />

<strong>Production</strong> Practices<br />

Hybrid Selection<br />

(Jerry Miller)<br />

Selection of sunfl ower hybrids to plant is one of the<br />

most important decisions a producer must make<br />

each season (Figure 8). First, three classes of hybrids<br />

- NuSun oilseed, traditional oilseed and confection<br />

hybrids are available,. Second, variables such as yield,<br />

quality factors, maturity, dry down, standability, and<br />

pest and disease tolerance, should be considered.<br />

NuSun Sunfl ower<br />

NuSun oilseed sunfl ower hybrids will produce an oil<br />

quality with more than 55 percent oleic fatty acid.<br />

This oil is in wide demand by the frying food industry<br />

and potentially could be a bottled oil. Some hybrid<br />

seed companies are providing a grower guarantee that<br />

their hybrids will make the minimum oleic grade.<br />

Some processors of NuSun sunfl ower also are providing<br />

contracts for producing seed of this quality. A<br />

premium may be paid to producers for planting NuSun<br />

hybrids.<br />

Traditional Sunfl ower<br />

Traditional oilseed sunfl ower hybrids have a high<br />

linoleic and lower oleic fatty acid quality in contrast<br />

with the NuSun hybrids. Traditional hybrids have been<br />

grown for their multipurpose marketability, with large<br />

export demand and hulling for the kernel market being<br />

most important.<br />

Confection Sunfl ower<br />

Confection sunfl ower hybrids are used primarily for<br />

in-shell and hulled kernel markets. They are characterized<br />

by having large seed, with a distinctive color<br />

striping on the hull. New hybrids with very long, large<br />

seed are in demand for the export market. Producers<br />

must be careful to set their combine concave widths<br />

properly to avoid hull damage on these hybrids. Producers<br />

generally plant confection hybrids at a lower<br />

plant population and increase insect scouting and<br />

control to maintain high kernel quality. Contracts are<br />

available to producers interested in planting confection<br />

hybrids.<br />

Criteria for Hybrid Selection<br />

Growers should use several criteria in hybrid selection.<br />

First, they should take an inventory of available hybrids<br />

being marketed in their area. Seed yield potential<br />

is an important trait to consider when looking at an<br />

available hybrid list. Yield trial results from university<br />

experiment stations, National Sunfl ower Associationsponsored<br />

trials and commercial companies should<br />

identify a dozen or so consistently high yielding<br />

hybrids for a particular area. Results from strip tests or<br />

demonstration plots on or near growers’ farms should<br />

■ Figure 8. A hybrid seed production fi eld of<br />

sunfl ower. Female and male parents are planted in<br />

alternate strips across the fi eld. (Marcia P. McMullen)<br />

Hybrid Selection<br />

11

12<br />

be evaluated. Yield results from previous years on an<br />

individual’s farm and information from neighbors also<br />

are valuable. The best producing hybrids in a region<br />

may produce approximately 2,300 pounds per acre<br />

with good soil fertility and favorable soil moisture, or<br />

more than 3,000 pounds per acre in the most favorable<br />

growing conditions.<br />

Oil percentage should be another trait to consider in<br />

oilseed hybrid selection. Several environmental factors<br />

infl uence oil percentage, but the hybrid’s genetic<br />

potential for oil percentage also is important. Current<br />

hybrids have oil percentages ranging from 38 percent<br />

to more than 50 percent. Domestic oil processors have<br />

been paying a premium based on market price for<br />

more than 40 percent oil (at 10 percent moisture) and<br />

discounts for oil less than 40 percent. Current recommendations<br />

are to select a high-oil hybrid instead of a<br />

low-oil hybrid with the same yield potential, but don’t<br />

sacrifi ce yield in favor of oil content.<br />

Maturity and dry down are important characteristics to<br />

consider when deciding what hybrid to plant. Maturity<br />

is especially important if planting is delayed, being<br />

mindful of the average killing frost in your area. Yield,<br />

oil content and test weight often are reduced when a<br />

hybrid is damaged by frost before it is fully mature.<br />

An earlier hybrid likely will be drier at harvest than a<br />

later hybrid, thus reducing drying costs. Also, consider<br />

planting hybrids with different maturity dates as a production<br />

hedge to spread risk and workload at harvest.<br />

The most economical and effective means to control<br />

sunfl ower diseases and other pests is planting resistant<br />

or tolerant hybrids and considering a minimum<br />

of three to four years’ rotation between successive<br />

sunfl ower crops. Hybrids are available with resistance<br />

to rust, Verticillium wilt and certain races of downy<br />

mildew. New hybrids may be available with tolerance<br />

to Sclerotinia head and stalk disease. Growers should<br />

check with their local seed dealer or sunfl ower seed<br />

company representative to obtain this information.<br />

Stalk quality, another trait to consider, provides resistance<br />

to lodging, various diseases and other pests. Hybrids<br />

with good stalk quality are easier to harvest and<br />

yield losses generally are reduced, withstanding damages<br />

from pests and high winds. Uniform stalk height<br />

at maturity is another important trait to consider.<br />

Hybrid selection may include selecting a hybrid with<br />

resistance to certain herbicides not previously available.<br />

This nontransgenic resistance either was derived<br />

from the wild species of sunfl ower or from mutagenesis.<br />

Sunfl ower hybrids can be sprayed with herbicides<br />

that control various broadleaf and grassy weeds either<br />

by one chemical or by a tank-mix of two chemicals.<br />

This technology will allow broad-spectrum weed control<br />

in minimum-till or no-till sunfl ower production,<br />

as well as with traditional production. Growers should<br />

check with their local seed dealer or sunfl ower seed<br />

company representative to obtain information regarding<br />

availability of these hybrids.<br />

The last item to consider is to purchase hybrid seed<br />

from a reputable seed company and dealer with a good<br />

technical service record. This is particularly important<br />

if producers have any questions regarding production<br />

practices. Companies and seed dealers provide different<br />

services, policies and purchase incentives, including<br />

credit, delivery service and returns.<br />

Semidwarf Sunfl ower<br />

(Duane Berglund)<br />

Semidwarf sunfl ower is 25 percent to 35 percent shorter<br />

than normal height hybrid sunfl ower. Research results<br />

show seed yield and oil content of semidwarf and<br />

normal height sunfl ower are similar in some years but<br />

not always. In drought stress years, seed yield of semidwarf<br />

sunfl ower was signifi cantly less than normalheight<br />

hybrids. Most semidwarf sunfl ower have early<br />

maturity ratings, thus the potential for high yields is<br />

limited, compared with conventional-height sunfl ower.<br />

The semidwarf plant types appear to be less susceptible<br />

to lodging, which could be very important during<br />

years of optimum plant growth or where sunfl ower<br />

is grown under irrigation, in high-plant populations.<br />

Generally, the semidwarf sunfl ower can be planted<br />

in narrowly spaced rows or solid seeded. University<br />

research indicates root penetration and water use<br />

to a depth of 6 feet is similar for normal height and<br />

semidwarf sunfl ower. Beyond 6 feet, root penetration<br />

of the semidwarf may not be as great as that of taller<br />

plant types. Some sunfl ower breeders have observed<br />

that short-stature plants have demonstrated limitations<br />

in head size and ability of the plant to fi ll the center of<br />

the head. Also, slower seedling emergence has been<br />

reported for semidwarfs.

Sunfl ower Branching<br />

(Duane Berglund)<br />

Sunfl ower branching is an undesirable trait in commercial<br />

sunfl ower production. It can be caused by the<br />

genetics of a hybrid, environmental infl uences and<br />

herbicide injury.<br />

Branching of various degrees can occur in sunfl ower,<br />

ranging from a single stem with a large single infl orescence<br />

in cultivated types to multiple branching<br />

from axils of most leaves on the main stem in the wild<br />

species. Branch length varies from a few centimeters<br />

to a distance longer than the main stem. Branching<br />

may be concentrated at the base or top of the stem or<br />

spread throughout the entire plant. Generally, heads<br />

on branches are smaller than heads on the main stem.<br />

Occasionally, some fi rst-order branches have a terminal<br />

head almost as large as the main head. In most<br />

wild species, the head on the main stem blooms fi rst,<br />

but generally is no larger than those on the branches.<br />

Studies on the genetics of top branching have shown<br />

that it is dominant over nonbranching and is controlled<br />

by a single gene. Sunfl ower literature reports that top<br />

branching in cultivated sunfl ower is controlled by a<br />

single dominant gene, but branching in wild species is<br />

controlled by duplicate dominant genes.<br />

Source: Sunfl ower Technology and <strong>Production</strong>,<br />

ASA monograph number 35.<br />

■ Figure 9. Soil Tests are the most reliable means<br />

for growers to determine fertilizer needs to obtain<br />

projected yield goals. (Dave Franzen)<br />

<strong>Production</strong> Practices<br />

Seed Quality<br />

(Duane Berglund)<br />

High quality, uniform seed with high germination,<br />

known hybrid varietal purity and freedom from weed<br />

seeds and disease should be selected to reduce production<br />

risks. The standard germination test provides an<br />

indication of performance under ideal conditions but<br />

is limited in its ability to estimate what will happen<br />

under stress. Accelerated aging is another method<br />

used to evaluate seed vigor. Any old or carry-over<br />

seed should have both types of tests conducted. Seed<br />

is sold on a bag weight basis or by seed count. Seed<br />

size designations are fairly uniform across companies.<br />

Most seed is treated with a fungicide and insecticide<br />

to protect the germinating seedling. Seed should be<br />

uniformly sized to allow precision in the planting<br />

operation.<br />

Soils<br />

(David Franzen)<br />

Sunfl ower is adapted to a variety of soil conditions,<br />

but grows best on well-drained, high water-holding<br />

capacity soils with a nearly neutral pH (pH 6.5-7.5).<br />

<strong>Production</strong> performance on high-stress soils, such as<br />

those affected by drought potential, salinity or wetness,<br />

is not exceptional but compares favorably with<br />

other commercial crops commonly grown.<br />

Soil Fertility<br />

(David Franzen)<br />

Sunfl ower, like other green plants, requires at least 16<br />

elements for growth. Some of these, such as oxygen,<br />

hydrogen and carbon, are obtained from water and the<br />

air. The other nutrients are obtained from the soil. Nitrogen,<br />

phosphorus and sulfur are frequently defi cient<br />

in soils in any climatic zone. Potassium, calcium and<br />

magnesium are frequently defi cient in high-rainfall<br />

areas. Defi ciencies of iron, manganese, zinc, copper,<br />

molybdenum, boron and chlorine are uncommon but<br />

can appear in many climatic zones.<br />

A sunfl ower yield of 2,000 pounds per acre requires<br />

approximately the same amount of nitrogen, phosphorus<br />

and potassium as 40 bushels per acre of wheat.<br />

Hybrid Selection and <strong>Production</strong> Practices<br />

13

14<br />

The nutrient content of the soil, as determined by a<br />

soil test, is the only practical way to predict probability<br />

of a response to applied nutrients (Figure 9). A soil<br />

test will evaluate the available nutrients in the soil and<br />

classify the soil as very low (VL), low (L), medium<br />

(M), high (H) or very high (VH) in certain nutrients.<br />

A fi eld classifi ed as very low in a nutrient will give a<br />

yield response to applied fertilizer 80 percent to 100<br />

percent of the time. A yield response is not always<br />

obtained because soil moisture or some other environmental<br />

factor may become limiting. A fi eld classifi ed<br />

as low will respond to applied fertilizer 40 percent<br />

to 60 percent of the time, a medium testing fi eld will<br />

respond to added fertilizer 10 percent to 20 percent<br />

of the time and a high-testing fi eld will respond to<br />

applied fertilizer only occasionally. <strong>Field</strong>s testing very<br />

high will not respond because the reserve of nutrients<br />

in the soil is adequate for optimum plant growth and<br />

performance.<br />

Fertilizer Recommendations<br />

(David Franzen)<br />

Soil tests have been developed to estimate sunfl ower’s<br />

potential response to fertilizer amendments. The most<br />

important factors in the fertilizer recommendations<br />

are the yield goal and the level of plant-available soil<br />

nutrients. In most climatic zones, predicting yield<br />

is impossible. Past yield records are a reasonable<br />

estimate of potential yield for the coming year. A yield<br />

goal for sunfl ower should be more optimistic than the<br />

average yield, and should approach the past maximum<br />

yield obtained by the grower on the same or a similar<br />

soil type. Nutrients not used by a crop in a dry growing<br />

season usually are not lost and can be used by the<br />

following crop.<br />

From an economic standpoint, having a yield goal that<br />

is somewhat high is much more benefi cial for a grower<br />

than having a goal that is too low. A low yield goal in<br />

a good growing season easily can mean lost income of<br />

$30 to $40 per acre. In contrast, a high yield goal in a<br />

dry growing season will result in a loss of only $1to<br />

$2 in additional interest on the cost of unused nutrients<br />

since most of the nutrients will be available to the<br />

subsequent crop.<br />

The amounts of nitrogen, phosphorus and potassium<br />

recommended for various sunfl ower yield goals and<br />

soil test levels are shown in Table 6. For yield goals<br />

not shown in the table, use the formulas at the base<br />

of the table. The data in this table are based on the<br />

amount of nitrate-nitrogen (NO 3 -N) in pounds per<br />

acre found in the top 2 feet of soil, the parts per million<br />

(ppm) of phosphorus (P) extracted from the top<br />

6 inches of soil by the 0.5N sodium bicarbonate, and<br />

the ppm of potassium (K) extracted by neutral normal<br />

ammonium acetate in the top 6 inches of soil<br />

Other nutrients are not usually defi cient for sunfl ower.<br />

On sandy slopes and hilltops, sulfur may be a problem;<br />

however, sulfur would not be expected to be defi -<br />

cient in higher organic matter, depressional soils. The<br />

sulfur soil test is a poor indicator of the probability of<br />

response to sulfur fertilizers. Sunfl ower has not been<br />

shown to be responsive to the application of other<br />

nutrients, including micronutrients in the state.<br />

Table 6. Nitrogen (N), phosphate (P 2 O 5 ) and<br />

potash (K 2 O) recommendations for sunfl ower in<br />

North Dakota.<br />

Yield<br />

Soil N<br />

plus<br />

fertilizer<br />

Soil Test Phosphorus, ppm<br />

VL L M H VH<br />

Goal N<br />

lb/acre-<br />

Bray-1 0-5 6-10 11-15 16-20 21+<br />

lb/acre 2 ft. Olsen 0-3 4-7 8-11 12-15 16+<br />

- - - - - - lb P2O5 /acre - - - - - -<br />

1,000 50 20 15 9 4 0<br />

1,500 75 31 22 14 5 0<br />

2,000 100 41 30 18 7 0<br />

2,500 125 51 37 23 9 0<br />

Nitrogen recommendation = 0.05 YG - STN - PCC<br />

(Bray-1) Phosphate recommendation = (0.0225-0.0011 STP)YG<br />

(Olsen) Phosphate recommendation = (0.0225-0.0014 STP)YG<br />

Yield<br />

Soil Test Potassium, ppm<br />

Goal 0-40 41-80 81-120 121-160 161+<br />

lb/acre VL L M H VH<br />

1,000 36 25 14 3 0<br />

1,500 53 37 21 5 0<br />

2,000 71 50 28 6 0<br />

2,500 89 62 35 8 0<br />

(K, ammonium acetate extractant) Potash recommendation =<br />

(0.04100-0.00027 STK)YG<br />

YG = Yield Goal<br />

PCC = Previous Crop Credit<br />

STN is the amount of NO 3 -N in the top 2 feet of soil<br />

STP, STK = Soil Test P or K, respectively<br />

VL,L,M, H,VH = very low, low, medium, high and very high,<br />

respectively

Fertilizer Application<br />

(Dave Franzen)<br />

Germinating sunfl ower seed is similar to corn in its<br />

reaction to seed-placed fertilizer. Application of more<br />

than 10 pounds per acre of nitrogen (N) plus potash<br />

(K 2 O) in a 30-inch row will result in reduced stands<br />

or injured seedlings. Dry soil conditions can increase<br />

the severity of injury. In row widths narrower than<br />

30 inches, rates of N plus K 2 O can be proportionally<br />

higher. For improved fertilizer rate fl exibility, starter<br />

fertilizer should be placed in bands at least 2 to 3<br />

inches from the seed row.<br />

Producers have several good reasons to apply nitrogen<br />

in the fall, such as availability of labor, soil conditions,<br />

etc. However, the general principle with respect<br />

to nitrogen application is: The longer the time period<br />

between application and plant use, the greater the<br />

possibility for N loss. In other words, use judgment<br />

in making a decision on time of N application. In the<br />

case of sandy soils, fall application of N is not recommended.<br />

In many instances, a side-dress application of<br />

N when the sunfl ower plants are about 12 inches high<br />

may be preferable.<br />

Phosphate and potash may be fall or spring applied<br />

before a tillage operation. These nutrients are not<br />

readily leached from soil because they form only<br />

slightly soluble compounds or attach to the soil. The<br />

phosphate and potash recommendations in Table 6.<br />

are broadcast amounts. The recommendations for soil<br />

that tests very low and low in P and K can be reduced<br />

by one-third the amount in the table when applied in a<br />

band at seeding. In minimum or no-till systems, phosphate<br />

and potash may be applied in a deeper band to<br />

reduce the buildup of nutrients at the soil surface that<br />

occurs with these systems. However, most comparisons<br />

among deep, shallow and surface applications<br />

have shown little difference in crop response.<br />

Water Requirements for Sunfl ower<br />

(Duane Berglund)<br />

Sunfl ower has deep roots and extracts water from<br />

depths not reached by most other crops; thus it is<br />

perceived to be a drought-tolerant crop. Sunfl ower has<br />

an effective root depth around 4 feet, but can remove<br />

water from below this depth. Research on side-by-side<br />

plots has shown that sunfl ower is capable of extracting<br />

more water than corn from an equal root zone volume.<br />

With its deep root system, it also can use nitrogen and<br />

other nutrients that leach below shallow-root crops;<br />

thus it is a good crop to have in a rotation.<br />

Seasonal water use by sunfl ower averages about 19<br />

inches under irrigated conditions. Under dryland<br />

conditions, sunfl ower will use whatever stored soil<br />

moisture and rain that it receives during the growing<br />

season. When access to water is not limited, small<br />

grains use 2 to 3 inches less total water than sunfl ower<br />

during the growing season, whereas soybean water use<br />

is slightly greater. Corn uses 1 to 4 inches, and sugar<br />

beets use 2 to 6 inches more than sunfl ower, respectively,<br />

during the growing season.<br />

These total water use values are typical for nondrought<br />

conditions in southeastern North Dakota. Small grains<br />

use the least total water since they have the fewest<br />

number of days from emergence to maturity. Sunfl ower<br />

and soybean have an intermediate number of days<br />

of active growth and corresponding relative water use.<br />

Corn ranks above sunfl ower in growth days and water<br />

use, while sugar beets rank highest in both categories.<br />

However, water use effi ciency does vary among these<br />

crops. Comparative water use effi ciency measured as<br />

grain (pounds per acre or lb/A) per inch of water used<br />

on three dryland sites and two years in eastern North<br />

Dakota was 119, 222, 307, 41, 218, 138, and 127 for<br />

sunfl ower, barley, grain corn, fl ax, pinto bean, soybean<br />

and wheat, respectively. These results indicated that<br />

corn had the highest water use effi ciency, sunfl ower<br />

and wheat were intermediate and fl ax the lowest.<br />

(Source: M. Ennen. 1979. Sunfl ower water use in<br />

eastern North Dakota, M.S. thesis, North Dakota State<br />

University).<br />

Fertility has little infl uence on total water use, but<br />

as fertility increases, water use effi ciency increases<br />

because yield increases. Yield performance has been<br />

shown to be a good indicator of water use effi ciency<br />

of sunfl ower hybrids; higher yielding hybrids exhibit<br />

the highest water use effi ciency.<br />

<strong>Production</strong> Practices<br />

15

16<br />

Soil Water Management<br />

for Dryland Sunfl ower<br />

(Duane Berglund)<br />

Management practices that promote infi ltration of<br />

water in the soil and limit evaporation from the soil<br />

generally will be benefi cial for sunfl ower production<br />

in terms of available soil moisture. Leaving stubble<br />

during the winter to catch snow and minimum tillage<br />

are examples. Good weed control also conserves<br />

moisture for the crop. The use of post-applied and preemergence<br />

herbicides with no soil incorporation also<br />

conserves moisture when growing sunfl ower.<br />

Sunfl ower has the ability to exploit a large rooting<br />

volume for soil water. <strong>Field</strong>s for sunfl ower production<br />

should be selected from those with the greater waterholding<br />

capacity and soils without layers that may<br />

restrict roots. Water-holding capacity depends mainly<br />

on soil texture and soil depth. The loam, silt loam,<br />

clay loam and silty clay loam textures have the highest<br />

water-holding capacities. Water-holding capacity of<br />

the soils in any fi eld can be obtained from county soil<br />

survey information available from local Natural Resources<br />

Conservation Service (NRCS) USDA offi ces.<br />

Sampling or probing for available soil moisture before<br />

planting also can help select fi elds for sunfl ower<br />

production. With other factors being equal, fi elds with<br />

the most stored soil moisture will have potential for<br />

higher yields. Where surface runoff can be reduced<br />

or snow entrapment increased by tillage or residue<br />

management, increases in stored soil moisture should<br />

occur and be benefi cial to a deep-rooted crop such as<br />

sunfl ower.<br />

Irrigation Management<br />

(Tom Scherer)<br />

Irrigation of sunfl ower by commercial growers is not<br />

common, but sunfl ower will respond to irrigation.<br />

Data collected by the USDA Farm Service Agency<br />

(FSA) for irrigated crops in North Dakota shows that<br />

an annual average of about 1,500 acres of sunfl ower<br />

are irrigated each year. Data for irrigated and dryland<br />

oil-type variety trials between 1975 and 1994 from the<br />

Carrington Research Extension Center show an aver-<br />

age yield differential of about 500 pounds per acre.<br />

However, some years the irrigated trials yielded more<br />

than 1,500 pounds per acre more than the dryland<br />

plots, and some years the dryland plots actually had<br />

greater yield than the irrigated plots.<br />

Irrigated sunfl ower seasonal water use averages about<br />

19 inches. With good water management, average<br />

water use will increase from about 0.03 inch per day<br />

soon after emergence to more than 0.27 inch per day<br />

from head emergence to full seed head development.<br />

However, during July and August, water use on a hot,<br />

windy day can exceed 0.32 inch.<br />

Research by Stegman and Lemert of NDSU has<br />

demonstrated the yield potential of sunfl ower grown<br />

under optimum moisture conditions and the effect of<br />

water stress at different growth stages. Sunfl ower yield<br />

is most sensitive to moisture stress during the fl owering<br />

period (R-2 to R-5.9 reproductive stages) and least<br />

sensitive during the vegetative period (emergence to<br />

early bud). A 20 percent reduction of irrigation water<br />

application from plant emergence to the R-2 stage<br />

resulted in only a 5 percent reduction in yield, but a<br />

20 percent reduction in irrigation water application<br />

during the R-2 to R-5.9 period resulted in a 50 percent<br />

yield reduction.<br />

If soil water content is near fi eld capacity at planting,<br />

research indicates that the fi rst irrigation could be<br />

delayed until the root zone soil moisture is about 70<br />

percent depleted. However, if pumping capacity is low<br />

(less than 800 gallons per minute, or gpm, for a 128acre<br />

center pivot), a lesser depletion is advisable due<br />

to inadequate “catch-up capacity.” Irrigations during<br />

the critical bud to ray-petal appearance (R-2 to R-5.0)<br />

period should be scheduled to maintain a low soil<br />

moisture stress condition (35 percent to 40 percent<br />

depletion). Irrigation should be avoided from R-5.1<br />

to R-5.9 because of the susceptibility of the sunfl ower<br />

plant to head rot from Sclerotinia (white mold). Irrigate<br />

just before fl owering in the bud stages R-3 to<br />

R-4. Soil moisture depletion again can approach 70<br />

percent during late seed fi ll and beyond with little or<br />

no depression in yield.<br />

Yield increases due to irrigation depend on several<br />

factors. Soil water-holding capacity and precipitation<br />

are two of the most important. Research indicates that<br />

the seed yield versus crop water use (ET) exhibits a<br />

linear relationship with a slope averaging 190 pounds<br />

per acre-inch. This means every additional inch of

water applied by irrigation will increase seed yield<br />

by about 190 pounds per acre. Remember that the<br />

research was performed on the loam and sandy-loam<br />

soils of Carrington and Oakes, N.D. A yield increase<br />

of 50 percent or more with irrigation may be expected<br />

almost every year on coarse-textured soils. However, a<br />

seed yield increase from irrigation may not always occur<br />

on soils with higher water-holding capacities and<br />

with adequate precipitation. Adequate soil fertility is<br />

very important in achieving the higher yield potential<br />

under irrigation.<br />

Management of applied irrigation water requires the<br />

combination of periodic soil moisture measurement<br />

with a method of irrigation scheduling. Soil moisture<br />

can be measured or estimated in a variety of ways. The<br />

simplest is the traditional “feel” method that is an art<br />

developed through time with extensive use and experience.<br />

For most irrigation water management applications,<br />

either the resistance block type of soil moisture<br />

measurement or tensiometers should be used. These<br />

are relatively inexpensive and require little labor to<br />

use effectively.<br />

The soil water balance method of irrigation scheduling,<br />

otherwise known as the checkbook method, is<br />

popular and well-documented. With this method,<br />

a continuous account is kept of the water stored in<br />

the soil. Soil water losses due to crop use and soil<br />

surface evaporation are estimated each day based on<br />

the maximum temperature and the days since crop<br />

emergence. Precipitation and irrigation are measured<br />

and added to the soil water account each day. Errors in<br />

estimating water use will accumulate through time, so<br />

periodically measuring the moisture in the soil profi le<br />

is necessary. Detailed instructions for using the checkbook<br />

method are published (North Dakota Extension<br />

publication AE-792). A computer program using this<br />

method also is available from the NDSU Agricultural<br />

and Biosystems Engineering Department.<br />

Another form of irrigation scheduling is to use estimated<br />

daily water use values for sunfl ower (Table 7).<br />

This method, sometimes called the “water use replacement<br />

method,” is based on obtaining daily estimates<br />

of sunfl ower water use and accurately measuring the<br />

amount of rain received on the fi eld. Irrigations are<br />

scheduled to replace the amount of soil moisture used<br />

by the sunfl ower minus the amount of rain received<br />

since the last irrigation. Estimates of daily sunfl ower<br />

water use can be obtained several ways. AE-792 has<br />

a table for sunfl ower water use throughout the season<br />

based on weeks’ past emergence and maximum daily<br />

air temperature. More accurate sunfl ower water use<br />

values, based on measured weather variables from<br />

the North Dakota Agricultural Weather Network<br />

(NDAWN), are available at the NDAWN Web site:<br />

http://ndawn.ndsu.nodak.edu/. Click on “Applications”<br />

on the left side of the home screen. Sunfl ower crop<br />

water use estimates can be obtained for the current<br />

growing season (between emergence and harvest)<br />

or for past growing seasons if you want to do some<br />

comparisons.<br />

Table 7. Average daily water use for sunfl ower in inches per day based on maximum daily air<br />

temperature and weeks past emergence. For example, during the eighth week after emergence,<br />

if the daily air temperature were 85 degrees on a particular day, sunfl ower water use for that<br />

day would be 0.25 inch.<br />

Maximum<br />

Daily Air<br />

Temperature<br />

Week After Emergence<br />

°F 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

50 to 59 0.01 0.03 0.05 0.06 0.08 0.08 0.08 0.08 0.08 0.08 0.08 0.07 0.06 0.04 0.03<br />

60 to 69 0.02 0.05 0.08 0.10 0.12 0.14 0.14 0.14 0.13 0.13 0.13 0.12 0.10 0.07 0.04<br />

70 to 79 0.03 0.07 0.11 0.15 0.17 0.19 0.19 0.19 0.19 0.18 0.17 0.16 0.13 0.10 0.06<br />

80 to 89 0.03 0.09 0.14 0.19 0.22 0.25 0.25 0.25 0.24 0.23 0.22 0.21 0.17 0.13 0.07<br />

Above 90 0.04 0.11 0.17 0.23 0.27 0.30 0.30 0.30 0.29 0.29 0.27 0.26 0.21 0.15 0.09<br />

Bud Ray Flower 100% Ray<br />

Anther Petal<br />

Drop<br />

<strong>Production</strong> Practices<br />

17

18<br />

Tillage, Seedbed Preparation<br />

and Planting<br />

(Roger Ashley and Don Tanaka)<br />

Sunfl ower, like other crops, requires proper seedbed<br />

conditions for optimum plant establishment. Errors<br />

made at planting time may be compounded throughout<br />

the growing season. Seedbed preparation, soil tilth,<br />

planting date, planting depth, row width, seed distribution<br />

and plant population should be nearly correct as<br />

conditions permit.<br />

Tillage and Seedbed Preparation<br />

Tillage traditionally has been used to control weeds<br />

and incorporate herbicides in preparation for planting.<br />

When tillage is used in low rainfall areas, producers<br />

must take care to control weeds while leaving as much<br />

of the previous crop’s residue intact as possible. Tillage<br />

never should occur when soils are too wet. Soils<br />

that are tilled when too wet and then dry will crust,<br />

turn lumpy and generally provide for poor seedbed<br />

conditions for germination and establishment.<br />

Maintaining a moist seedbed is important if producers<br />

expect to have uniform germination and emergence<br />

across the fi eld (Figure 10). Poor germination<br />

and emergence will infl uence the need for and the<br />

effectiveness of future management practices. Excessive<br />

tillage should be avoided where tillage is used<br />

to prepare the seedbed or to incorporate preplant<br />

herbicides. Excessive tillage will break down soil<br />

structure, cause compaction and crusting problems,<br />

reduce aeration, restrict water movement and provide<br />

■ Figure 10. No-till one pass seeding systems<br />

preserve soil moisture and ground cover when water<br />

is limited. (Roger Ashley)<br />

conditions favorable for infection by downy mildew or<br />