Product Data Sheet - Performa Mesh, Mesh Cable Tray ... - Clipsal

Product Data Sheet - Performa Mesh, Mesh Cable Tray ... - Clipsal

Product Data Sheet - Performa Mesh, Mesh Cable Tray ... - Clipsal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

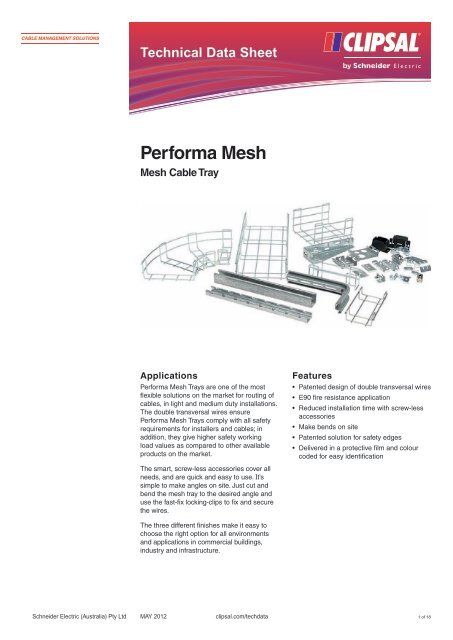

Technical <strong>Data</strong> <strong>Sheet</strong><br />

<strong>Performa</strong> <strong>Mesh</strong><br />

<strong>Mesh</strong> <strong>Cable</strong> <strong>Tray</strong><br />

Applications<br />

<strong>Performa</strong> <strong>Mesh</strong> <strong>Tray</strong>s are one of the most<br />

flexible solutions on the market for routing of<br />

cables, in light and medium duty installations.<br />

The double transversal wires ensure<br />

<strong>Performa</strong> <strong>Mesh</strong> <strong>Tray</strong>s comply with all safety<br />

requirements for installers and cables; in<br />

addition, they give higher safety working<br />

load values as compared to other available<br />

products on the market.<br />

The smart, screw-less accessories cover all<br />

needs, and are quick and easy to use. It’s<br />

simple to make angles on site. Just cut and<br />

bend the mesh tray to the desired angle and<br />

use the fast-fix locking-clips to fix and secure<br />

the wires.<br />

The three different finishes make it easy to<br />

choose the right option for all environments<br />

and applications in commercial buildings,<br />

industry and infrastructure.<br />

Schneider Electric (Australia) Pty Ltd MAY 2012<br />

clipsal.com/techdata<br />

Features<br />

• Patented design of double transversal wires<br />

• E90 fire resistance application<br />

• Reduced installation time with screw-less<br />

accessories<br />

• Make bends on site<br />

• Patented solution for safety edges<br />

• Delivered in a protective film and colour<br />

coded for easy identification<br />

1 of 18

Specifications<br />

Technical and material data<br />

Steel wire Specification C4D: EN 10016-2-3<br />

C7D: EN 10016-2-3<br />

AISI 304 (Stainless steel): EN 10088-2<br />

Density 7.85kg/m³<br />

Surface treatment Electro-zinc (>8µm): EN 12329-1<br />

Hot-dip galvanised (>70 µm): ENISO 1461<br />

(Stainless steel)<br />

Steel sheet Specification Dx51D+Z275 MA-C<br />

Dx51D+ZM175 MA-C<br />

Density 7.85kg/m³<br />

Surface treatment Electro-zinc (>8µm): EN 12329-1<br />

Hot-dip galvanised (>70µm): ENISO 1461<br />

(Stainless steel)<br />

Resistance to impact IK-10 (EN 50102)<br />

Temperature range From –40°C to +120°C<br />

Fire resistance E90 classified (DIN 4102-12)<br />

Standards The products comply with the standards:<br />

• IEC 61537<br />

– Loading and deflection<br />

– Electrical continuity across couplers<br />

– System with electrical continuity<br />

• IEC 60068-2-75 (resistance to impact)<br />

• EN ISO 9227 (salt spray test)<br />

Dimensions<br />

Detailed dimensions<br />

<strong>Mesh</strong> tray size Longitudinal Transversal<br />

Height x width (mm) Length (mm) wire Ø (mm) wire Ø (mm)<br />

35 x 100<br />

3000<br />

4.4<br />

3.9<br />

35 x 150<br />

3000<br />

4.4<br />

3.9<br />

35 x 200<br />

3000<br />

4.4<br />

3.9<br />

35 x 300<br />

3000<br />

4.4<br />

3.9<br />

60 x 60 3000 4.4 3.9<br />

70 x 100<br />

3000<br />

4.4<br />

3.9<br />

70 x 150<br />

3000<br />

4.4<br />

3.9<br />

70 x 200<br />

3000<br />

4.9<br />

3.9<br />

70 x 300(*)<br />

3000<br />

4.9<br />

3.9<br />

70 x 400(*)<br />

3000<br />

4.9<br />

3.9<br />

70 x 500(*)<br />

3000<br />

4.9<br />

3.9<br />

70 x 600(*)<br />

3000<br />

4.9<br />

3.9<br />

105 x 200(*)<br />

3000<br />

4.9<br />

3.9<br />

105 x 300(*)<br />

3000<br />

4.9<br />

3.9<br />

105 x 400(*)<br />

3000<br />

4.9<br />

3.9<br />

105 x 500(*)<br />

3000<br />

4.9<br />

3.9<br />

105 x 600(*)<br />

Note:<br />

3000<br />

4.9<br />

3.9<br />

(*) The longitudinal wire Ø for the stainless steel range is 4.4mm.<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 2 of 18

<strong>Cable</strong> capacity<br />

<strong>Mesh</strong> tray size Height (mm) Width (mm) Cross section (mm²)<br />

35 x 100<br />

35 x 150<br />

35 x 200<br />

35 x 300<br />

35<br />

35<br />

35<br />

35<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 3 of 18<br />

100<br />

150<br />

200<br />

300<br />

2688<br />

4288<br />

5888<br />

9088<br />

60 x 60 60 60 2666<br />

70 x 100<br />

70 x 150<br />

70 x 200<br />

70 x 300(*)<br />

70 x 400(*)<br />

70 x 500(*)<br />

70 x 600(*)<br />

105 x 200(*)<br />

105 x 300(*)<br />

105 x 400(*)<br />

105 x 500(*)<br />

105 x 600(*)<br />

70<br />

70<br />

70<br />

70<br />

70<br />

70<br />

70<br />

105<br />

105<br />

105<br />

105<br />

105<br />

100<br />

150<br />

200<br />

300<br />

400<br />

500<br />

600<br />

200<br />

300<br />

400<br />

500<br />

600<br />

5268<br />

9112<br />

12,328<br />

19,028<br />

25,728<br />

32,428<br />

39,128<br />

18,768<br />

28,968<br />

39,168<br />

49,368<br />

59,568<br />

Note:<br />

* Unless it is stated in the country’s regulations, we suggest the following orientative values to determine the<br />

cable tray to be installed:<br />

• Fill factor value to be applied to the cross-sectional area of the cables: 80% for power cables and 40% for<br />

data cables<br />

• Enlargement factor: 30%.

Typical Installation<br />

Overall View Ceiling Suspended Solutions<br />

Components<br />

1. Ceiling bracket omega 10. Fast-fix suspended bracket<br />

2. Vertical/suspended/floor bracket 11. Support for box/bracket<br />

3. Beam clamp 12. Fast-fix hanger 35<br />

4. Profile fast-fixing + profile 21 x 41/41 x 41 13. Central suspension support<br />

5. Pendant bracket 14. ID label<br />

6. Swivel support + U-profile 15. C-shape support<br />

7. Extendable joint 16. Take-off plate<br />

8. Cover fixing 17. Earthing clamp<br />

9. Cover 18. L-shape support.<br />

EZ: Electro zinc – indoor installations, not aggressive atmosphere (office building and commercial<br />

shopping centres).<br />

HDG: Hot-dip galvanisation – indoor installations, aggressive atmosphere, tunnels, underground,<br />

outdoor installations and urban locations.<br />

SS: Stainless steel – chemical industries, acid and alkaline atmosphere, food industry,<br />

atmospheres with halogen. Other possible applications may include harbours, marinas and water<br />

treatment facilities.<br />

LZ: Lamellar zinc is a zinc and aluminium coating with a degree of resistance to severe<br />

atmospheres, comparable to that of hot-dip galvanised steel. It is used for small items, to achieve<br />

a smooth surface.<br />

BC: Bi-chromate (according to 12329-1) is a process that deposits a thin layer of zinc over the<br />

steel through an electro-chemical process, with an additional passivation that gives a typical yellow<br />

colour. The benefits of this process are control over zinc thickness and smoother surfaces.<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 4 of 18

Overall View Wall and Floor-Mounted Solutions<br />

Components<br />

1. <strong>Mesh</strong> tray 11. Fast-fix horizontal bracket<br />

2. Horizontal bracket set 12. <strong>Cable</strong> drop-out<br />

3. Pendant bracket + U-profile 13. Fast-fix divider<br />

4. Horizontal bracket omega 14. Vertical/suspended/floor bracket<br />

5. Coupler 15. ID label<br />

6. Side coupler 16. Support for box + bracket<br />

7. Fast coupler 70 + 105 17. Insulating floor support<br />

8. Locking clip for flat bends 18. Vertical/suspended/floor bracket<br />

9. Horizontal bracket 19. Adjustable bracket set.<br />

10. Spring nut + profile 2121/4141<br />

EZ: Electro zinc – indoor installations, not aggressive atmosphere (office building and commercial<br />

shopping centres).<br />

HDG: Hot dip galvanisation – indoor installations, aggressive atmosphere, tunnels, underground,<br />

outdoor installations and urban locations.<br />

SS: Stainless steel – chemical industries, acid and alkaline atmosphere, food industry,<br />

atmospheres with halogen. Other possible applications may include harbours, marinas and water<br />

treatment facilities.<br />

LZ: Lamellar zinc is a zinc and aluminium coating with a degree of resistance to severe<br />

atmospheres, comparable to that of hot dip galvanised steel. It is used for small items, to achieve<br />

a smooth surface.<br />

BC: Bi-chromate (according to 12329-1) is a process that deposits a thin layer of zinc over the<br />

steel through an electro-chemical process, with an additional passivation that gives a typical<br />

yellow colour. The benefits of this process are control over zinc thickness and smoother surfaces.<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 5 of 18

Cat.<br />

Number<br />

Description<br />

<strong>Mesh</strong> <strong>Tray</strong>s Electro-Zinc<br />

4511110 <strong>Mesh</strong> <strong>Tray</strong> 35 x 100 EZ<br />

4511115 <strong>Mesh</strong> <strong>Tray</strong> 35 x 150 EZ<br />

4511120 <strong>Mesh</strong> <strong>Tray</strong> 35 x 200 EZ<br />

4511130 <strong>Mesh</strong> <strong>Tray</strong> 35 x 300 EZ<br />

<strong>Mesh</strong> <strong>Tray</strong>s Hot-Dip Galvanised<br />

4512110 <strong>Mesh</strong> <strong>Tray</strong> 35 x 100 HDG<br />

4512115 <strong>Mesh</strong> <strong>Tray</strong> 35 x 150 HDG<br />

4512120 <strong>Mesh</strong> <strong>Tray</strong> 35 x 200 HDG<br />

4512130 <strong>Mesh</strong> <strong>Tray</strong> 35 x 300 HDG<br />

<strong>Mesh</strong> <strong>Tray</strong>s Stainless Steel<br />

4515110 <strong>Mesh</strong> <strong>Tray</strong> 35 x 100 SS<br />

4515115 <strong>Mesh</strong> <strong>Tray</strong> 35 x 150 SS<br />

4515120 <strong>Mesh</strong> <strong>Tray</strong> 35 x 200 SS<br />

4515130 <strong>Mesh</strong> <strong>Tray</strong> 35 x 300 SS<br />

Cat.<br />

Number<br />

Description<br />

<strong>Mesh</strong> <strong>Tray</strong>s Electro-Zinc<br />

4511230 <strong>Mesh</strong> <strong>Tray</strong> 70 x 300 EZ<br />

4511240 <strong>Mesh</strong> <strong>Tray</strong> 70 x 400 EZ<br />

4511250 <strong>Mesh</strong> <strong>Tray</strong> 70 x 500 EZ<br />

4511260 <strong>Mesh</strong> <strong>Tray</strong> 70 x 600 EZ<br />

<strong>Mesh</strong> <strong>Tray</strong>s Hot-Dip Galvanised<br />

4512230 <strong>Mesh</strong> <strong>Tray</strong> 70 x 300 HDG<br />

4512240 <strong>Mesh</strong> <strong>Tray</strong> 70 x 400 HDG<br />

4512250 <strong>Mesh</strong> <strong>Tray</strong> 70 x 500 HDG<br />

4512260 <strong>Mesh</strong> <strong>Tray</strong> 70 x 600 HDG<br />

<strong>Mesh</strong> <strong>Tray</strong>s Stainless Steel<br />

4515230 <strong>Mesh</strong> <strong>Tray</strong> 70 x 300 SS<br />

4515240 <strong>Mesh</strong> <strong>Tray</strong> 70 x 400 SS<br />

4515250 <strong>Mesh</strong> <strong>Tray</strong> 70 x 500 SS<br />

4515260 <strong>Mesh</strong> <strong>Tray</strong> 70 x 600 SS<br />

Parts List and Safe Working Loads<br />

The safe working load is calculated according to the Standard IEC 61537. See diagrams below.<br />

• The load is uniformly distributed along the mesh trays.<br />

• The maximum distance between couplers and brackets is 1/5 of the span between brackets.<br />

• The safety working load value is given when:<br />

• the longitudinal deflection is

Cat.<br />

Number<br />

Description<br />

<strong>Mesh</strong> <strong>Tray</strong>s Electro-Zinc<br />

4511206 <strong>Mesh</strong> <strong>Tray</strong> 60 x 60 EZ<br />

4511210 <strong>Mesh</strong> <strong>Tray</strong> 70 x 100 EZ<br />

4511215 <strong>Mesh</strong> <strong>Tray</strong> 70 x 150 EZ<br />

4511220 <strong>Mesh</strong> <strong>Tray</strong> 70 x 200 EZ<br />

<strong>Mesh</strong> <strong>Tray</strong>s Hot-Dip Galvanised<br />

4512206 <strong>Mesh</strong> <strong>Tray</strong> 60 x 60 HDG<br />

4512210 <strong>Mesh</strong> <strong>Tray</strong> 70 x 100 HDG<br />

4512215 <strong>Mesh</strong> <strong>Tray</strong> 70 x 150 HDG<br />

4512220 <strong>Mesh</strong> <strong>Tray</strong> 70 x 200 HDG<br />

<strong>Mesh</strong> <strong>Tray</strong>s Stainless Steel<br />

4515206 <strong>Mesh</strong> <strong>Tray</strong> 60 x 60 SS<br />

4515210 <strong>Mesh</strong> <strong>Tray</strong> 70 x 100 SS<br />

4515215 <strong>Mesh</strong> <strong>Tray</strong> 70 x 150 SS<br />

4515220 <strong>Mesh</strong> <strong>Tray</strong> 70 x 200 SS<br />

Cat.<br />

Number<br />

Description<br />

<strong>Mesh</strong> <strong>Tray</strong>s Electro-Zinc<br />

4511320 <strong>Mesh</strong> <strong>Tray</strong> 105 x 200 EZ<br />

4511330 <strong>Mesh</strong> <strong>Tray</strong> 105 x 300 EZ<br />

4511340 <strong>Mesh</strong> <strong>Tray</strong> 105 x 400 EZ<br />

4511350 <strong>Mesh</strong> <strong>Tray</strong> 105 x 500 EZ<br />

4511360 <strong>Mesh</strong> <strong>Tray</strong> 105 x 600 EZ<br />

<strong>Mesh</strong> <strong>Tray</strong>s Hot-Dip Galvanised<br />

4512320 <strong>Mesh</strong> <strong>Tray</strong> 105 x 200 HDG<br />

4512330 <strong>Mesh</strong> <strong>Tray</strong> 105 x 300 HDG<br />

4512340 <strong>Mesh</strong> <strong>Tray</strong> 105 x 400 HDG<br />

4512350 <strong>Mesh</strong> <strong>Tray</strong> 105 x 500 HDG<br />

4512360 <strong>Mesh</strong> <strong>Tray</strong> 105 x 600 HDG<br />

<strong>Mesh</strong> <strong>Tray</strong>s Stainless Steel<br />

4515320 <strong>Mesh</strong> <strong>Tray</strong> 105 x 200 SS<br />

4515330 <strong>Mesh</strong> <strong>Tray</strong> 105 x 300 SS<br />

4515340 <strong>Mesh</strong> <strong>Tray</strong> 105 x 400 SS<br />

4515350 <strong>Mesh</strong> <strong>Tray</strong> 105 x 500 SS<br />

4515360 <strong>Mesh</strong> <strong>Tray</strong> 105 x 600 SS<br />

Load Kg/m<br />

Load Kg/m<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

200<br />

185<br />

170<br />

155<br />

140<br />

125<br />

110<br />

95<br />

80<br />

65<br />

50<br />

0<br />

1m<br />

1m<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 7 of 18<br />

1.25m<br />

1.25m<br />

1.50m<br />

Span<br />

1.50m<br />

Span<br />

1.75m<br />

1.75m<br />

2m<br />

2m

Admissible working-load on brackets<br />

The safe working-load is calculated according to the standard IEC 61537.<br />

See diagrams below:<br />

• The load is uniformly distributed along the bracket<br />

• The safety working-load value is given when the deflection is ≤5% of the width of the bracket.<br />

Horizontal wall solutions<br />

Cat. No. Load kg* Cat. No. Load kg*<br />

Horizontal bracket 45xx110 324 Fast-fix horizontal 45xx110 324<br />

45xx115 306<br />

bracket<br />

45xx115 306<br />

45xx120 273 45xx120 273<br />

45xx130 214 45xx130 214<br />

45xx140 191 45xx140 191<br />

45xx150 178 45xx150 178<br />

45xx160 154 45xx160 154<br />

Horizontal bracket set 45xx210 418 Horizontal bracket 45xx310 198<br />

45xx215 428<br />

omega<br />

45xx315 121<br />

45xx220 345 45xx320 100<br />

45xx230 331 45xx330 78<br />

45xx240 315<br />

45xx250 250<br />

45xx260 190<br />

Ceiling-suspended solutions<br />

Suspended bracket 45xx310 51 Reinforced<br />

45xx620 505<br />

45xx315 52<br />

suspended bracket<br />

45xx630 481<br />

45xx320 59 45xx640 515<br />

45xx330 62 45xx650 442<br />

45xx340 56 45xx660 460<br />

45xx350 42<br />

45xx360 35<br />

Horizontal bracket 45xx410 264 Swivel support + 45xx410 + 90<br />

omega<br />

45xx415<br />

45xx420<br />

154<br />

107<br />

U-profile<br />

+ pendant bracket<br />

45xx420 +<br />

45xx910<br />

45xx430 85 45xx410 +<br />

45xx420 +<br />

45xx915<br />

85<br />

45xx410 +<br />

45xx420 +<br />

45xx920<br />

45xx410 +<br />

45xx420 +<br />

45xx930<br />

45xx410 +<br />

45xx420 +<br />

45xx940<br />

45xx410 +<br />

45xx420 +<br />

45xx950<br />

45xx410 +<br />

45xx420 +<br />

45xx960<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 8 of 18<br />

80<br />

70<br />

60<br />

50<br />

40

Admissible working load on brackets (continued).<br />

Ceiling-suspended solutions<br />

Ref. No. Load kg* Load kg*<br />

double¹)<br />

Fast-fix suspended 45xx510 127 –<br />

bracket<br />

45xx520 138 –<br />

45xx530 98 –<br />

45xx540 70 250<br />

45xx550 60 230<br />

45xx560 49 170<br />

45xx570 – 140<br />

45xx580 – 140²)<br />

45xx590 – 140²)<br />

Note:<br />

¹ ) Two brackets back-to-back, fixed together with bolts.<br />

² ) Per metre, with a maximum distance between two threaded rods of 950mm. The<br />

threaded rods must be placed all along the bracket.<br />

* These values refer to all the surface treatments available for each bracket.<br />

XX in ref no. refers to finish (EZ or HDG)<br />

i.e. 45xx110 - xx (for full cat. number please refer to TPG).<br />

Resistance to traction<br />

1 U-profile +<br />

1 pendant<br />

bracket<br />

1 L-shape<br />

support<br />

1 C-shape<br />

support<br />

1 Threaded<br />

rod M6-M8<br />

Resistance to<br />

traction (kg)<br />

1000<br />

362<br />

400<br />

100<br />

According to the standard IEC 61537<br />

1: Measuring point for the deformation<br />

F: Strength<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 9 of 18<br />

1<br />

F

Recommended couplers<br />

<strong>Mesh</strong> tray<br />

size<br />

Options for side-coupling<br />

(the quantity equals the sum of both sides)<br />

Side couplers Couplers Fast couplers<br />

Couplers used as<br />

central couplers<br />

35 x 100<br />

Not required<br />

35 x 150<br />

35 x 200<br />

2 2 2<br />

1<br />

1<br />

35 x 300 2<br />

60 x 60 2 2 2 Not required<br />

70 x 100<br />

Not required<br />

70 x 150 2 2 2<br />

1<br />

70 x 200 1<br />

70 x 300<br />

2<br />

70 x 400<br />

70 x 500<br />

2 4 2<br />

2<br />

3<br />

70 x 600 3<br />

105 x 200<br />

1<br />

105 x 300 2<br />

105 x 400 2 4 4<br />

2<br />

105 x 500 3<br />

105 x 600 3<br />

Recommended fixings for brackets<br />

Width of mesh tray<br />

(mm)<br />

No. of fixings for all kinds of<br />

brackets<br />

60 1 Profile fast-fixings, fixings<br />

100 1<br />

150 2<br />

200 2<br />

300 3<br />

400 4<br />

500 4<br />

600 4<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 10 of 18

Available<br />

Surface treatments for all environments<br />

EZ = Electro-zinc<br />

HDG = Hot-dip galvanised<br />

SS = Stainless steel<br />

Accessories also available<br />

PG = Pre-galvanised<br />

LZ = Lamellar zinc<br />

BC = Bi-chromate<br />

Indoor installations, unaggressive atmosphere (office building,<br />

commercial malls)<br />

Indoor installations, aggressive atmosphere, tunnels,<br />

underground<br />

Outdoor installation, urban location<br />

Chemical industries, acid and alkaline atmosphere<br />

Harbours, marinas and water treatment<br />

Food industry<br />

Atmosphere with halogen<br />

Electrozinc<br />

EZ<br />

Hot-dip<br />

galvanised<br />

HDG<br />

Recommended<br />

Stainless<br />

steel<br />

SS<br />

EZ: Electro-zinc (according to EN 12329-1) is a process that deposits a thin layer of zinc over the<br />

steel through an electro-chemical process, with an additional passivation that gives a typical shiny<br />

grey colour. The benefits of this process are control over zinc thickness and smoother surfaces.<br />

HDG: Hot-dip galvanisation (EN ISO 1461) is the process of coating steel with a zinc layer, by<br />

passing the steel through a molten bath of zinc at a temperature of more than 400 °C. The result is a<br />

surface treatment that protects the steel from environmental elements.<br />

SS: Stainless steel AISI 304 (EN 10088-2) offers a high resistance to aggressive atmospheres. The<br />

pickling and passivation processes taking place after manufacturing improve the degree of protection<br />

of the steel.<br />

PG: Pre-galvanised steel (EN 10346) is carbon steel that has gone through a zinc bath just after<br />

rolling. Good protection against oxidation and rust.<br />

LZ: Lamellar zinc is a zinc and aluminium coating with a degree of resistance to severe atmosphere<br />

comparable to that of hot dip galvanised steel. It is used for small items to achieve a smooth surface.<br />

BC: Bi-chromate (according to 12329-1) is a process that deposits a thin layer of zinc over the steel<br />

through an electro-chemical process, with an additional passivation that gives a typical yellow colour.<br />

The benefits of this process are control over zinc thickness and smoother surfaces.<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 11 of 18

Instructions for Making Accessories<br />

The <strong>Performa</strong> <strong>Mesh</strong> <strong>Tray</strong>s are delivered with a protective transparent plastic film. Forget about dust<br />

and humidity! Each mesh tray also has a colour code for easy identification of the surface treatment.<br />

How to cut the mesh trays Coupling of all elements<br />

L<br />

470<br />

B<br />

130<br />

MÁX 3 mm<br />

MÁX 3 mm<br />

Kg<br />

2,7<br />

Fast-fixing of large radius flat bends<br />

L<br />

B<br />

Part number<br />

45 xx 900<br />

L<br />

Height<br />

(mm)<br />

18 21<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 12 of 18<br />

B<br />

Width<br />

(mm)<br />

B<br />

L<br />

Part number<br />

45 xx 110<br />

L<br />

Height<br />

(mm)<br />

B<br />

Width<br />

(mm)<br />

23.5 23.5<br />

Torque<br />

12<br />

Value of recommended torque.

How to cut to obtain different kind of angles<br />

C 1<br />

W<br />

mm<br />

C 3<br />

W<br />

mm<br />

C 5<br />

W<br />

mm<br />

60 100 150 200 300 400 500 600<br />

o o o o o o o o<br />

20 13 10 7 5 4 3 2<br />

Approximate angles.<br />

60 100 150 200 300 400 500 600<br />

o o o o o o o o<br />

125 85 55 37 25 19 15,5 12<br />

Approximate angles.<br />

60 100 150 200 300 400 500 600<br />

o o o o o o o o<br />

180 135 90 67 45 34 27 22<br />

Approximate angles.<br />

60 100 150 200 300 400 500 600<br />

o o o o o o o o<br />

145 100 65 44 30 23 18,5 C14 5<br />

Practical application of the various cuts.<br />

How to obtain the same angle with different bending<br />

radii function of numbers of cuts.<br />

Example:<br />

For a mesh tray width of W = 300, to realise<br />

an angle of 60°.<br />

OPTION 1: 3 cuts (20° + 20° + 20°)<br />

OPTION 2: 2 cuts (30° + 30°)<br />

These examples can apply for any width of mesh trays.<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 13 of 18<br />

C 2<br />

W<br />

mm<br />

C 4<br />

W<br />

mm<br />

60 100 150 200 300 400 500 600<br />

o o o o o o o o<br />

90 64 45 30 20 15 12.5 10<br />

Approximate angles.<br />

Approximate angles.<br />

W (mm)<br />

Corte 60 100 150 200 300 400 500 600<br />

C1 20° 13° 10° 7° 5° 4° 3° 2°<br />

C2 90° 64° 45° 30° 20° 15° 12.5° 10°<br />

C3 125° 85° 55° 37° 25° 19° 15.5° 12°<br />

C4 145° 100° 65° 44° 30° 23° 18.5° 14°<br />

C5 180° 135° 90° 67° 45° 34° 27° 22°<br />

W<br />

mm<br />

60 100<br />

o o<br />

180 135

Large radius flat bends<br />

L<br />

C 2<br />

WW<br />

60 100 150 200 300 400 500 600<br />

C1<br />

C2<br />

C3<br />

r<br />

x4<br />

255<br />

x2<br />

+<br />

x1<br />

200<br />

x2<br />

50<br />

x3<br />

75<br />

x2<br />

+<br />

x2<br />

110<br />

x6<br />

175<br />

x8<br />

225<br />

x9<br />

260<br />

L 450 450 210 310 550 600 760 900<br />

780 780 335 480 930 930 1225 1370<br />

Necessary<br />

length<br />

C 1<br />

mm<br />

L<br />

r o<br />

90<br />

Coupling of large radius bends<br />

L<br />

B<br />

Part number<br />

45 xx 900<br />

L<br />

Height<br />

(mm)<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 14 of 18<br />

C 2<br />

B<br />

Width<br />

(mm)<br />

18 21<br />

C 1<br />

C 2<br />

C 3<br />

W<br />

W = 100 mm<br />

W<br />

W = 300 mm<br />

C 3<br />

C 2<br />

C 2<br />

C 3<br />

C 3<br />

C 1<br />

C 2<br />

C 3<br />

C 2<br />

C 2<br />

C 3<br />

C 1

Right-angle flat bends<br />

W<br />

mm<br />

60 100 150 200 300 400 500 600<br />

(approx.)<br />

Coupling of right angle flat bends<br />

B<br />

L<br />

Part number<br />

45 xx 110<br />

ALLOW<br />

MOUNTING LIDS<br />

L<br />

Height<br />

(mm)<br />

B<br />

Width<br />

(mm)<br />

23.5 23.5<br />

ALLOW<br />

MOUNTING LIDS<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 15 of 18<br />

Torque<br />

12<br />

Value of recommended torque<br />

W<br />

mm<br />

2<br />

3<br />

60 100 150 200 300 400 500 600<br />

1<br />

L<br />

(approx.)<br />

L

T-junction (90˚ radius)<br />

ALLOW<br />

MOUNTING LIDS<br />

1<br />

2<br />

60 100 150 200 300 400 500 600<br />

Cut matches with transversal mesh<br />

(approx.)<br />

L<br />

Coupling of T-junction (90˚ radius)<br />

B<br />

L<br />

Part number<br />

45 xx 110<br />

L<br />

Height<br />

W<br />

B<br />

Width<br />

23,5 23,5<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 16 of 18<br />

Torque<br />

12<br />

Value of recommended torque<br />

2<br />

5<br />

1<br />

3<br />

L= W<br />

L<br />

4<br />

W

Reducer<br />

W<br />

mm<br />

1<br />

2<br />

3<br />

60 100 150 200 300 400 500 600<br />

L= W-W 1<br />

L W 1<br />

Coupling of reducers<br />

B<br />

L<br />

W<br />

Part number<br />

45 xx 110<br />

ALLOW<br />

MOUNTING LIDS<br />

(approx.)<br />

L<br />

Height<br />

(mm)<br />

B<br />

Width<br />

(mm)<br />

23.5 23.5<br />

ALLOW<br />

MOUNTING LIDS<br />

Schneider Electric (Australia) Pty Ltd clipsal.com/techdata 17 of 18<br />

Torque<br />

12<br />

Value of recommended torque.

Raisers:<br />

Schneider Electric (Australia) Pty Ltd<br />

33-37 Port Wakefield Road,<br />

Gepps Cross, South Australia 5094<br />

Contact us clipsal.com/feedback<br />

National Customer Care Enquiries:<br />

1300 2025 25<br />

V1.1<br />

C n1<br />

C n2<br />

C n3<br />

Angles according to flat<br />

convex<br />

concave concave convex<br />

35<br />

de 0 a 180º<br />

From 0 to 180º<br />

de 0 a 155º<br />

From 0 to 155º<br />

45º<br />

45º<br />

45º<br />

45º<br />

60/70<br />

de 0 a 180º<br />

From 0 to 180º<br />

de 0 a 90º<br />

From 0 to 90º<br />

25º<br />

25º<br />

25º<br />

25º<br />

105<br />

de 0 a 180º<br />

From 0 to 180º<br />

de 0 a 60º<br />

From 0 to 60º<br />

15º<br />

15º<br />

15º<br />

15º<br />

Coupling of raisers:<br />

B<br />

L<br />

Part number<br />

45 xx 110<br />

L<br />

Height<br />

(mm)<br />

B<br />

Width<br />

(mm)<br />

23.5 23.5<br />

Torque<br />

12<br />

C n3<br />

C n1<br />

35<br />

60/70<br />

105<br />

Value of recommended torque.<br />

CONCAVE CONVEX<br />

CONVEX<br />

CONCAVE<br />

convex concave<br />

r<br />

65 185 315 450<br />

25<br />

0<br />

-<br />

x1 x2 x3 x4 x1<br />

r<br />

125 220 300<br />

90 180 250<br />

50 150 250<br />

x2 x3 x4<br />

18 of 18<br />

Radius according to flat<br />

convex<br />

o<br />

90<br />

concave<br />

C n1<br />

r<br />

o<br />

90<br />

r<br />

Schneider Electric (Australia) Pty Ltd reserves the right to change specifications, modify designs<br />

and discontinue items without incurring obligation and whilst every effort is made to ensure that<br />

descriptions, specifications and other information in this document are correct, no warranty is<br />

given in respect thereof and the company shall not be liable for any error therein.<br />

© 2012 Schneider Electric. All Rights Reserved.<br />

Trademarks are owned by Schneider Electric Industries SAS or its affiliated companies.<br />

CLIPCOM24642 April 2012