Abstract

Purpose

Daniellia oliveri sheds a large quantity of leaves in the dry season in sub-Saharan Africa. Retort carbonization is a recent biomass conversion technique where the flue gas generated in the product zone is re-combusted in the heating zone to produce BC. This work shows that good-quality biochar (DO-BC) can be obtained from the retort carbonization of these leaves. We also show that the utilization of cow dung as co-feed improves the quality of the BC obtained (DC-BC).

Methods

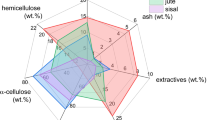

The process was conducted at ambient pressure and 100 min of process time. The BC yield for DO-BC was 28.01% at a peak temperature of 382.2 °C and 38.69% for DC-BC at a peak temperature of 361.6 °C. The BCs were characterized by Scanning Electron Microscopy (SEM), Energy Dispersive Xray Spectroscopy (EDS), Fourier transform infrared spectroscopy (FTIR), Differential Thermal Analysis/Thermogravimetric Analysis (DTA/TGA), and Brunauer–Emmett–Teller (BET) analysis.

Results

The specific surface increased from 114 m2/g for DO-BC to 174 m2/g for DC-BC respectively. Cow dung co-feed led to significant morphological differences in the BC. DC-BC had more surface heterogeneity and more inorganic elements. The average roughness was 31.25 × 103 μm for DO-BC and 29.21 × 103 μm for DC-BC respectively. Functional groups like C–H, C–O, C=C, O–H, and C–N were observed in the BCs and the cow dung co-feed led to more C–O and C–H functional groups in the BC. The BCs showed similar thermal characteristics with a maximum thermal degradation temperature of around 400 °C.

Conclusions

It was surmised that the systematic addition of a secondary component to the feedstock can improve the yield and surface properties of the final BC obtained.

Graphical Abstract

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article (and its supplementary information files).

References

Banerjee, P., et al.: Solid waste management in India: a brief review, in Waste management and resource efficiency, pp. 1027–1049. Springer, New York (2019)

Rizzo, L., et al.: Consolidated vs new advanced treatment methods for the removal of contaminants of emerging concern from urban wastewater. Sci. Total Environ. 655, 986–1008 (2019)

Hoornweg, D., Bhada-Tata, P.: What a waste: a global review of solid waste management, vol. 15. World Bank, Washington, DC (2012)

Ighalo, J.O., Adeniyi, A.G.: Biomass to biochar conversion for agricultural and environmental applications in Nigeria: challenges, peculiarities and prospects. Mater. Int. 2(2), 111–116 (2020)

Marshall, R.E., Farahbakhsh, K.: Systems approaches to integrated solid waste management in developing countries. Waste Manage. 33(4), 988–1003 (2013)

Adewole, A.T.: Waste management towards sustainable development in Nigeria: a case study of Lagos state. Int. NGO J. 4(4), 173–179 (2009)

Yakubu, O.E., Otitoju, O., Onwuka, J.: Gas chromatography–mass spectrometry (GC–MS) analysis of aqueous extract of Daniellia oliveri stem bark. Pharm. Anal. Acta 8(11), 1–8 (2017)

Fohouo, F.-N.T., et al.: Oraging behaviour of Apis mellifera Adansonii Latreille (Hymenoptera: Apidae) on Daniellia oliveri, Delonix regia, Hymenocardia acida and Terminalia mantaly flowers in Ngaoundéré (Cameroon). Int. J. Biol. Chem. Sci. 4(4), 1180–1190 (2010)

Eletta, A.A.O., Tubi, O.T., Ighalo, J.O.: Adsorption of pb(II) from aqueous media using mesoporous adsorbents obtained from Daniellia oliveri leaves. World Sci. News 148, 90–107 (2020)

Ighalo, J.O., Eletta, O.A.A., Adeniyi, A.G.: Biomass carbonisation in retort kilns: process techniques, product quality and future perspectives. Bioresource Technol. Rep. 17, 100934 (2022)

Schure, J., et al.: Efficiency of charcoal production in Sub-Saharan Africa: solutions beyond the kiln, p. 340. Bois & Forets Des Tropiques, Jabalpur (2019)

Rodrigues, T., Junior, A.B.: Charcoal: a discussion on carbonization kilns. J. Anal. Appl. Pyrol. 143, 104670 (2019)

Ighalo, J.O., Onifade, D.V., Adeniyi, A.G.: Retort-heating carbonisation of almond (Terminalia catappa) leaves and LDPE waste for biochar production: evaluation of product quality. Int. J. Sustain. Energ. 14(5), 1059–1067 (2021)

Njenga, M., et al.: Charcoal production and strategies to enhance its sustainability in Kenya. Dev. Pract. 23(3), 359–371 (2013)

Duku, M.H., Gu, S., Hagan, E.B.: Biochar production potential in Ghana—a review. Renew. Sustain. Energy Rev. 15(8), 3539–3551 (2011)

Shahack-Gross, R.: Herbivorous livestock dung: formation, taphonomy, methods for identification, and archaeological significance. J. Archaeol. Sci. 38(2), 205–218 (2011)

Matos, J.S., et al.: Evaluation of the reduction of methane emission in swine and bovine manure treated with black soldier fly larvae (Hermetia illucens L.). Environ. Monit. Assess. 193, 1–17 (2021)

Puri, S., et al.: Extraction of lignocellulosic constituents from cow dung: preparation and characterisation of nanocellulose. Biomass Convers. Biorefinery 13, 1–10 (2020)

Susianti, B., Warmadewanthi, I., Tangahu, B.V.: Characterization and experimental evaluation of cow dung biochar + dolomite for heavy metal immobilization in solid waste from silica sand purification. Bioresource Technol. Rep. 18, 101102 (2022)

Holm-Nielsen, J.B., Seadi, T.A., Oleskowicz-Popiel, P.: The future of anaerobic digestion and biogas utilization. Bioresour. Technol. 100(22), 5478–5484 (2009)

Ahmad, A., et al.: Removal of methylene blue dye using rice husk, cow dung and sludge biochar: characterization, application, and kinetic studies. Bioresour. Technol. 306, 123202 (2020)

Chen, X., et al.: Cow dung-based biochar materials prepared via mixed base and its application in the removal of organic pollutants. Int. J. Mol. Sci. 23(17), 10094 (2022)

Sharma, B., Suthar, S.: Enriched biogas and biofertilizer production from Eichhornia weed biomass in cow dung biochar-amended anaerobic digestion system. Environ. Technol. Innov. 21, 101201 (2021)

Lin, J.-C., et al.: Integrated thermochemical conversion process for valorizing mixed agricultural and dairy waste to nutrient-enriched biochars and biofuels. Bioresour. Technol. 328, 124765 (2021)

Adeniyi, A.G., et al.: Thermochemical conversion of African balsam leaves-cow dung hybrid wastes into biochar. Biofuels Bioprod. Biorefin. 17(3), 510–522 (2023)

Adeniyi, A.G., Ighalo, J.O., Onifade, D.V.: Production of bio-char from plantain (Musa paradisiaca) fibers using an updraft biomass gasifier with retort heating. Combust. Sci. Technol. 193(1), 60–74 (2021)

Adeniyi, A.G., Ighalo, J.O., Onifade, D.V.: Production of bio-char from plantain (Musa paradisiaca) fibers using an updraft biomass gasifier with retort heating. Combust. Sci. Technol. 193(1), 60–74 (2019)

Ighalo, J.O., Adeniyi, A.G., Igwegbe, C.A.: 3D reconstruction and morphological analysis of electrostimulated hyperthermophile biofilms of Thermotoga neapolitana. Biotechnol. Lett. 43(7), 1303–1309 (2021)

Chandrasekaran, A., et al.: Natural draft-improved carbonization retort system for biocarbon production from Prosopis juliflora biomass. Energy Fuels 33(11), 11113–11124 (2019)

Padakan, R.: Effect of the flue of charcoal retort kilns on production charcoal using drum kilns for households. Int. J. Eng. Technol. (2019). https://doi.org/10.7763/IJET.2019.V11.1155

Adeniyi, A.G., Ighalo, J.O., Onifade, D.V.: Biochar from the thermochemical conversion of orange (Citrus sinensis) peel and albedo: product quality and potential applications. Chem. Afr. 3(2), 439–448 (2020)

Alagbe, J.: Daniellia oliveri leaf extracts as an alternative to antibiotic feed additives in broiler chicken diets: meat quality and fatty acid composition. Indonesian J. Innov. Appl. Sci. (IJIAS) 1(3), 177–186 (2021)

Kiyasudeen, S.K., et al.: Characterization of fresh cattle wastes using proximate, microbial, and spectroscopic principles. Am.-Eurasian J. Agric. Environ. Sci. 15(8), 1700–1709 (2015)

Tsai, C.-Y., et al.: Engineered mesoporous biochar derived from rice husk for efficient removal of malachite green from wastewaters. Bioresour. Technol. 347, 126749 (2022)

Emenike, E.C., et al.: Delonix regia biochar potential in removing phenol from industrial wastewater. Bioresource Technol. Rep. 19, 101195 (2022)

Zhang, S.-Z., et al.: Biochar based functional materials as heterogeneous catalysts for organic reactions. Curr. Opin. Green. Sustainable Chem. 38, 100713 (2022)

Aboyade, A.O., et al.: Non-isothermal kinetic analysis of the devolatilization of corn cobs and sugar cane bagasse in an inert atmosphere. Thermochim. Acta. 517(1–2), 81–89 (2011)

Mani, T., et al.: Pyrolysis of wheat straw in a thermogravimetric analyzer: effect of particle size and heating rate on devolatilization and estimation of global kinetics. Chem. Eng. Res. Des. 88(8), 952–958 (2010)

Bayartsengel, B., et al.: Characterization of biochars produced from various biowastes: in 5th international conference on chemical investigation and utilization of natural resource (ICCIUNR-2021). Atlantis Press, Amsterdam (2021)

Garba, J., et al.: Evaluation of adsorptive characteristics of cow dung and rice husk ash for removal of aqueous glyphosate and aminomethylphoshonic acid. Sci. Rep. 9(1), 17689 (2019)

Adeniyi, A.G., et al.: Thermal energy recovery and valorisation of Delonix regia stem for biochar production. Environ. Challenges 9, 100630 (2022)

Qu, J., et al.: Magnetic porous biochar with high specific surface area derived from microwave-assisted hydrothermal and pyrolysis treatments of water hyacinth for Cr (VI) and tetracycline adsorption from water. Bioresour. Technol. 340, 125692 (2021)

Saliu, O.D., et al.: Microwave exfoliation of a biochar obtained from updraft retort carbonization for supercapacitor fabrication. Electrochem. Commun. 139, 107308 (2022)

Zhou, S., et al.: The influence of manure feedstock, slow pyrolysis, and hydrothermal temperature on manure thermochemical and combustion properties. Waste Manage. 88, 85–95 (2019)

Chand, N., Kumar, K., Suthar, S.: Cattle dung biochar-packed vertical flow constructed wetland for nutrient removal: effect of intermittent aeration and wastewater COD/N loads on the removal process. J. Water Process. Eng. 43, 102215 (2021)

Yusefi, M., et al.: Performance of cow dung reinforced biodegradable poly (lactic acid) biocomposites for structural applications. J. Polym. Environ. 26, 474–486 (2018)

Yang, X., et al.: Sorptive removal of ibuprofen from water by natural porous biochar derived from recyclable plane tree leaf waste. J. Water Process. Eng. 46, 102627 (2022)

El-Shafie, A.S., et al.: Techno-economic assessment of waste mandarin biochar as a green adsorbent for binary dye wastewater effluents of methylene blue and basic fuchsin: lab-and large-scale investigations. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 306, 123621 (2024)

Campion, L., et al.: The costs and benefits of biochar production and use: a systematic review. J. Clean. Prod. 408, 137138 (2023)

Ighalo, J.O., et al.: Competitive adsorption of heavy metals in a quaternary solution by sugarcane bagasse—LDPE hybrid biochar: equilibrium isotherm and kinetics modelling. Chem Prod Proc Model 18, 1–15 (2022)

Adelodun, A.A., et al.: Thermochemical conversion of oil palm fiber-LDPE hybrid waste into biochar. Biofuels Bioprod. Biorefining 14(6), 1313–1323 (2020)

Funding

There was no external funding for the study.

Author information

Authors and Affiliations

Contributions

JOI (conceptualization; data curation; methodology; writing—original draft; writing—review & editing; resources), CAA (conceptualization; data curation; methodology), KOI (writing—original draft; writing - review & editing), ECE (writing—original draft; writing—review & editing), AGA (conceptualization; writing—review & editing; supervision; validation; project administration; resources).

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Ethical Approval

No Ethical approval was required for the study.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ighalo, J.O., Adeyanju, C.A., Iwuozor, K.O. et al. Retort Co-carbonization of Daniellia oliveri Leaves: Effect of Cow Dung Co-feed on Biochar Properties. Waste Biomass Valor (2024). https://doi.org/10.1007/s12649-024-02461-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12649-024-02461-z