Abstract

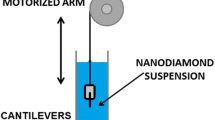

The surface of samples in atomic force microscopy is studied using cantilevers, which are an elastic console with a sharp needle at the free end. The quality of images obtained with an atomic force microscope (AFM) depends to a large extent on the degree of sharpness of the needle. Single-crystal silicon cantilevers made based on wet anisotropic etching are widely used. In this paper, the dependence of the shape and size of the formed needle on the KOH concentration in the solution is studied. The influence of pyrogenic oxidation and oxidation in an atmosphere of dry oxygen on the sharpness of the needle during the sharpening process is studied. It is determined that at a 70% KOH concentration, needles are formed that have the highest aspect ratio and maximum height. In this case, the shape of the needle is an octagonal pyramid, the side faces of which are formed by eight crystallographic planes of {311} and {131}. It is shown that a two-stage process of sharpening, consisting of pyrogenic oxidation and oxidation in an atmosphere of dry oxygen, makes it possible to form sufficiently sharp probes with a tip radius of 2–5 nm and an apex angle of 14° to 24°, while a one-stage process of needle sharpening based on pyrogenic oxidation produces probes with a radius of about 14 nm. Comparative tests of the fabricated probes are carried out. Using an AFM, images of a test sample of a polycrystalline silicon film with hemispherical grains (HSG-Si) are obtained. It is determined that a statistical parameter such as the relative increment of the surface area Sdr is the most sensitive to the sharpness of the probe for HSG-Si type film surfaces.

Similar content being viewed by others

REFERENCES

Burt, D.P., Dobson, P.S., Donaldson, L., and Weaver, J.M.R., A simple method for high yield fabrication of sharp silicon tips, Microelectron. Eng., 2008, vol. 85, no. 3, pp. 625–630. https://doi.org/10.1016/j.mee.2007.11.010

Wolter, O., Bayer, Th., and Greschner, J., Micromachined silicon sensors for scanning force microscopy, J. Vacuum Sci. Technol., 1990, vol. 9, no. 2, pp. 1353–1357. https://doi.org/10.1116/1.585195

Li, J., Xie, J., Xue, W., and Wu, D., Fabrication of cantilever with self-sharpening nano-silicon-tip for AFM applications, Microsyst. Technol., 2013, vol. 19, no. 2, pp. 285–290. https://doi.org/10.1007/s00542-012-1622-x

Zhang, X., Yu, X., Li, T., and Wang, Y., A novel method to fabricate silicon nanoprobe array with ultra-sharp tip on (111) silicon wafer, Microsyst. Technol., 2018, vol. 24, no. 7, pp. 2913–2917. https://doi.org/10.1007/s00542-017-3687-z

Han, J., Lu, S., Li, Q., Li, X., and Wang, J., Anisotropic wet etching silicon tips of small opening angle in KOH solution with the additions of I2/KI, Sens. Actuators, A, 2009, vol. 152, no. 1, pp. 75–79. https://doi.org/10.1016/j.sna.2009.03.008

Brugger, J., Buser, R.A., and de Rooij, N.F., Silicon cantilevers and tips for scanning force microscopy, Sens. Actuators, A, 1992, vol. 34, no. 3, pp. 193–200. https://doi.org/10.1016/0924-4247(92)85002-J

Folch, A., Wrighton, M.S., and Schmidt, M.A., Microfabrication of oxidation-sharpened silicon tips on silicon nitride cantilevers for atomic force microscopy, J. Microelectromech. Syst., 1997, vol. 6, no. 4, pp. 303–306. https://doi.org/10.1109/84.650126

Marcus, R.B., Ravi, T.S., Gmitter, T., et al., Formation of silicon tips with <1 nm radius, Appl. Phys. Lett., 1990, vol. 56, no. 3, pp. 236–238. https://doi.org/10.1063/1.102841

Ravi, T.S., Marcus, R.B., and Liu, D., Oxidation sharpening of silicon tips, J. Vacuum Sci. Technol. B, vol. 9, no. 6, pp. 2733–2737. https://doi.org/10.1116/1.585680

Dey, R.K., Shen, J., and Cui, B., Oxidation sharpening of silicon tips in the atmospheric environment, J. Vacuum Sci. Technol., 2017, vol. 35, no. 6, p. 06GC01. https://doi.org/10.1116/1.4998561

He, H., Zhang, J., Yang, J., and Yang, F., Silicon tip sharpening based on thermal oxidation technology, Microsyst. Technol., 2017, vol. 23, no. 6, pp. 1799–1803. https://doi.org/10.1007/s00542-016-2941-0

Marcus, R.B. and Sheng, T.T., The oxidation of shaped silicon surfaces, J. Electrochem. Soc., 1982, vol. 129, no. 6, pp. 1278–1282. https://doi.org/10.1149/1.2124118

Novak, A.V. and Novak, V.R., Influence of the probe sizes on the parameters of the surface morphology of hemispherical-grain polysilicon films: Estimation via atomic-force microscopy, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech., 2016, vol. 10, no. 5, pp. 949–958. https://doi.org/10.1134/S1027451016050104

Novak, A.V., Formation of hemispherical-grain polycrystalline silicon films for capacitor structures with increased capacitance, Izv. Vyssh. Uchebn. Zaved., Elektron., 2013, no. 6 (104), pp. 10–16.

Novak, A.V., Novak, V.R., Smirnov, D.I., and Rumyantsev, A.V., Features of the morphology and structure of thin silicon films, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech., 2021, vol. 15, no. 1, pp. 152–157. https://doi.org/10.1134/S1027451021010298

Zubel, I., Silicon anisotropic etching in alkaline solutions III: On the possibility of spatial structures forming in the course of Si(100) anisotropic etching in KOH and KOH+IPA solutions, Sens. Actuators, A, 2000, vol. 84, nos. 1–2, pp. 116–125. https://doi.org/10.1016/S0924-4247(99)00347-7

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Novak, A.V., Novak, V.R. & Rumyantsev, A.V. Features of the Manufacturing Process of Silicon Needles for Cantilevers. Russ Microelectron 51, 521–527 (2022). https://doi.org/10.1134/S1063739722070071

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739722070071