In the late 2000’s, rumors circulated about a bunker in Iran struck by a bunker-buster bomb. The bomb had failed to penetrate—and remained embedded in—the surface of the bunker, presumably until the occupants called in a bomb-disposal team. Rather than smashing through the concrete, the bomb had been unexpectedly stopped dead.

The reason was not hard to guess. Iran was a leader in the new technology of Ultra High Performance Concrete, or UHPC. Evidently, their latest was too much for standard bunker busters.

Dr. Stephanie Barnett of the University of Portsmouth in the U.K. is involved in developing stronger concrete to protect civilian buildings against terrorist attacks, pushing the envelope of ever-better protection. She has heard the story and understands the see-saw balance between offense and defense. While civilian audiences have been enthusiastic, she occasionally hears less positive responses from military personnel attending her presentations.

“One officer told me, ‘If you make this stronger blast- and impact-resistant material, we need to think about how to get through it,’” Barnett tells Popular Mechanics.

Better concrete forces bunker busters to raise their game. In 2005, Israel—which has had a longstanding interest in Iran as a potential target—requested new, more powerful bunker-busting weapons from the U.S., and these were eventually supplied in 2009. The GBU-28 is a 5,000-pound bomb with roughly four times the penetrating power of the 2,000-pound GBU-31v3 previously supplied to the Israeli Air Force.

Now, Israel is raising the bar again with a request for the United States Air Force’s (USAF) new GBU-72 “Advanced 5K Penetrator” bomb, which is not yet in service and was only tested for the first time last October. Like the GBU-28, it’s a 5,000-pounder, but with a significant improvement on the earlier weapon—although the Air Force will not give details.

The development of the GBU-72 and Israel’s urgent desire for it might be signals that in the quiet arms race between concrete and bombs, the concrete is winning.

Bunker Busting Basics

The USAF introduced its first modern bunker buster in 1985. General-purpose bombs have a thin steel casing filled with explosives; the bunker buster had a narrower profile, with a thicker casing and less explosives. This design concentrates all the weight on a smaller area, making it an ice pick rather than a hammer, so the bomb can smash through concrete or burrow through earth to strike deeply-buried targets.

While the same general-purpose bombs are being used as they were in the 90s, bunker busters had to go through several generations of upgrades. In the early 2000s, the Air Force even developed a special type of steel for the purpose, known as Eglin Steel, in association with steel specialist Ellwood National Forge Company.

Eglin Steel is a low-carbon, low-nickel steel with traces of tungsten, chromium, manganese, silicon, and other elements, each contributing a desirable property to the whole. Eglin Steel is the gold standard for bunker-busting munitions, although in recent years it has been supplemented by new USAF-96 steel, which boasts similar performance but is easier to produce and work with.

Materials scientists distinguish between the two qualities of toughness and hardness, and it is the balance between them that drives arms races between weapons and armor.

For example, when a soft lead bullet strikes a Kevlar vest, the bullet crumples and deforms, losing energy because it lacks hardness. Give the bullet a hard steel jacket though, and the Kevlar gives way. The counter is to make armor harder, by adding ultra-hard ceramic plates made out of materials like boron carbide. These are so hard that steel-jacketed bullets break up on impact. This led to special armor-piercing bullets tipped with hard tungsten. When these hit a ceramic plate, the plate breaks up in a process known as brittle failure.

The bunker-buster arms race is similar, but while the attackers have the advantage of steel, defense is based on concrete, which starts with a built-in disadvantage. “Concrete is inherently brittle,” says Professor Phil Purnell, an expert in concrete technology at the University of Leeds. “It is good at being squashed, not being stretched. The weakness is in its tensile capacity and toughness.” Purnell notes that while some modern concrete is actually stronger than aluminum, its brittleness is its Achilles Heel, and it gives way by cracking.

However, this changed with the advent of the type of concrete known as UHPC. Previously, a yield strength of 5,000 pounds per square inch (psi) was enough for concrete to be rated as “high strength,” with the best going up to 10,000 psi. The new UHPC can withstand 40,000 psi or more.

The greater strength is achieved by turning concrete into a composite material with the addition of steel or other fibers. These fibers hold the concrete together and prevent cracks from spreading throughout it, negating the brittleness. “Instead of getting a few large cracks in a concrete panel, you get lots of smaller cracks,” says Barnett. “The fibers give it more fracture energy.”

Fracture energy is defined as the amount of energy needed to split a material open. The concrete absorbs the incoming kinetic energy of a projectile as it fractures, slowing it right down and stopping it from penetrating. Naturally, researchers have been experimenting with finding the optimal mix of fibers for UHPC. More is better, but there is a limit. “The problem is that if you put in more than about one percent of steel fiber, it starts to clump together,” says Purnell. “The clever trick [is] how do you mix in more than one percent of fiber into the concrete.”

Various teams around the world have been working with techniques to mix fibers successfully. Much of this work is carried out by the military; but as Barnett notes, in her experience, the military sometimes come and ask questions to civilian researchers but never say anything about their own work. In the field of impact-resistant concrete—a minority interest in civil work—they may be some way ahead of their civilian counterparts.

When the USAF needed a new bunker buster in a hurry...

In January 1991, when the U.S. was leading the operation to Kuwait, U.S. intelligence discovered something alarming. The Iraqis had built a series of new command bunkers around Baghdad deep underground and protected by several feet of reinforced concrete, estimated to be invulnerable to the USAF’s existing 2,000-pound bunker busters.

A crash program was launched to build a new 5,000-pound bomb for the job. The USAF asked for ideas on January 18, and work commenced immediately at the Air Force Research Laboratory Munitions Directorate at Eglin Air Force Base, Florida. There was no time to fabricate bomb casings from scratch, so surplus 8-inch howitzer barrels were used as the basis of the bomb body, hand-filled with explosive, with a new nose section added. The first prototypes were delivered to the USAF less than a month later; in a rocket-sled test, the new weapon penetrated over 20 feet of concrete.

Two operational bombs were flown to the theater on 27 February and delivered by F-111Fs. Six seconds after impact on one of the new Iraq bunkers, smoke poured from the entrance, showing the bunker had been breached and destroyed. The day was saved by a munition developed six weeks flat.

But will the Air Force win the next round of bunker-busting so easily?

Are There Really Invulnerable Bunkers?

In 2012, the USAF launched a project to evaluate the challenge posed by bunkers made of UHPC. The Air Force ended up developing its own version of UHPC, known appropriately enough as Eglin high-strength concrete, for the testing process.

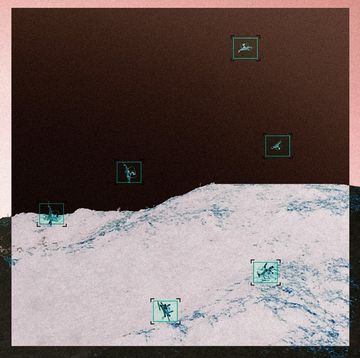

While the results of the USAF study are classified, an open-source Chinese study compared normal high-strength concrete with fiber-reinforced UHPC. Projectiles smashed through the reinforced concrete targets, but the UHPC targets survived with only minor cracking, and projectiles “either embedded in or rebounded from” the targets.

The Air Force was already concerned that even its 5,000-pound bombs were not sufficient, and in 2011, it received the Massive Ordnance Penetrator (MOP), a colossal 30,000-pound bomb. This was even bigger than the celebrated 21,000-pound Massive Ordnance Air Blast (MOAB, or ‘mother of all bombs’), to bust the deepest and toughest bunkers with sheer kinetic energy. MOP is about as big a bomb as you can fly—only the B-2 Spirit strategic bomber has the capacity—so smaller 2,000- and 5,000-pound weapons will still need to do most of the work against lesser targets.

After the concrete study, the Air Force upgraded the MOP. Then it upgraded it again. By 2018, it was on its fourth upgrade. Similar upgrades were made to smaller weapons.

The problem is that even the biggest bomb possible, made of the toughest material available, may no longer be able to hack it. Dr. Gregory Vartanov, of Toronto-based Advanced Materials Development Corp, claims high-grade UHPC is simply too strong for bombs made with existing steels. “Penetrators with monolithic cases made from materials such as… Eglin Steel … cannot penetrate bunkers made from UHPC,” Vartanov notes in a February 2021 piece in Aerospace & Defense Technology magazine, basing his claim on open-source penetration formulas.

But that is not the end of the story. UHPC is good, but even better protection is already being tested in the laboratory.

Concrete Is Getting Even Stronger

Recent work from China describes Functionally Graded Cementitious Composite, or FGCC, made by layering different types of high-performance concrete with different properties. The thin outer layer is extra-hard aggregate-reinforced UHPC; beneath this is a thick layer of hybrid fiber-reinforced UHPC optimized to resist cracking. Finally, there is a layer of tough steel fiber-reinforced UHPC. As Purnell explains, each layer has a different effect.

“You’ve got that hard outer layer to damage the projectile, then there is the thick layer with the mass to absorb its energy, and then the inner layer is there to catch the bits,” says Purnell. This inner, anti-spall layer, ensures that if the concrete does crack, no fragments (or “spalling”) get through into the bunker beyond.

According to Chinese research published in June, FGCC resisted penetration and explosion far better than UHPC: “penetration depth, crater area, and penetration damage were decreased greatly by the synergistic effects of high-strength fibers and coarse aggregates.” Barnett says that she has worked on a similar concept, and that this technique of layering materials with different properties could be more effective than any single material.

The latest research follows at least four years of Chinese study into layered concrete, with a particular focus on absorbing impacts and blasts. Expect new bunkers to be very tough nuts to crack.

Faster and Smarter Ways to Bust Bunkers

There is limited scope for making bunker busters bigger and badder, but there are other approaches. The arms race may not continue along the same path but take off in a different direction.

“Hypersonic weapons offer a new potential mode of attack against hardened bunkers,” says Justin Bronk of the U.K. defense think tank RUSI. Hypersonics are missiles which travel through the atmosphere at speeds in excess of Mach 5. Equipped with tungsten penetrators, they could act as ‘rods from god,’ punching through layered concrete like an armor-piercing bullet. With no explosive warhead, such weapons do damage by kinetic energy alone.

Bronk notes also that it is not always necessary to actually destroy a bunker. You can damage the entrances, take out the aerials, and cut off communication to a command bunker with hits in the right places. In military terms, it might as well be a crater, even if the occupants are unharmed.

The USAF will understandably not discuss its current bunker-busting capabilities or how they stack up against potential targets in Iran, China, or elsewhere. And most of the military work on high-strength concrete is similarly classified.

The U.S. military relies heavily on airpower to hold targets at risk. Adversaries may try to hide their command headquarters or nuclear facilities underground, but bunker busters give them no refuge. Incremental improvements in the prosaic field of concrete technology might have far-reaching strategic implications if they can blunt the edge of air power.